Please note that some content is only available in Japanese

OBAYASHI CORPORATION TECHNOLOGY RESEARCH INSTITUTE OL3

Japan’s first reuse of structural components from a demolished building in new construction

POINT

-

Reused in a completely different building—structure, design, and purpose

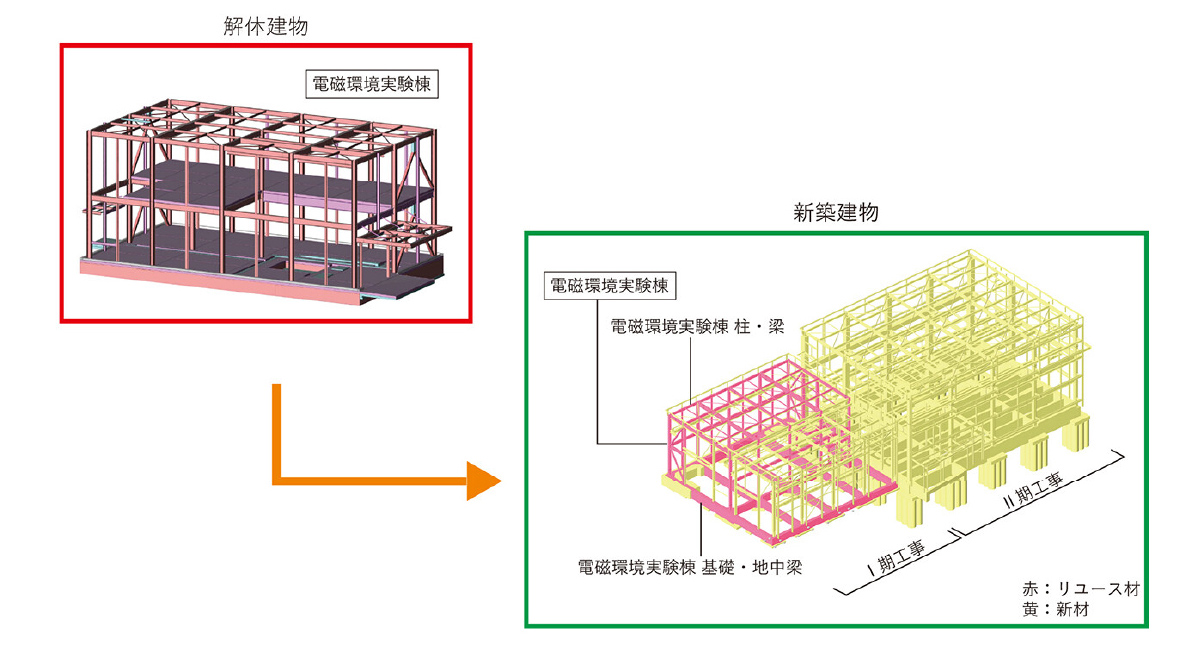

Demolished building: Electromagnetic Environment Test Building, steel-frame, 2 stories (completed in 1993)

Obayashi is undertaking Japan’s first initiative to reuse structural components—such as steel and concrete—that are typically melted down or crushed for recycling after building demolition, by incorporating them directly into the structure of a new building. This is being implemented in the construction of the Open Lab 3 (OL3) experimental facility at the Obayashi Technology Research Institute.

-

New building: Rendering of Open Lab 3 (OL3) upon completion

-

netZEB achieved through insulation performance, high-efficiency equipment, and solar power generation

-

Not restoration—repurposing into an entirely new building

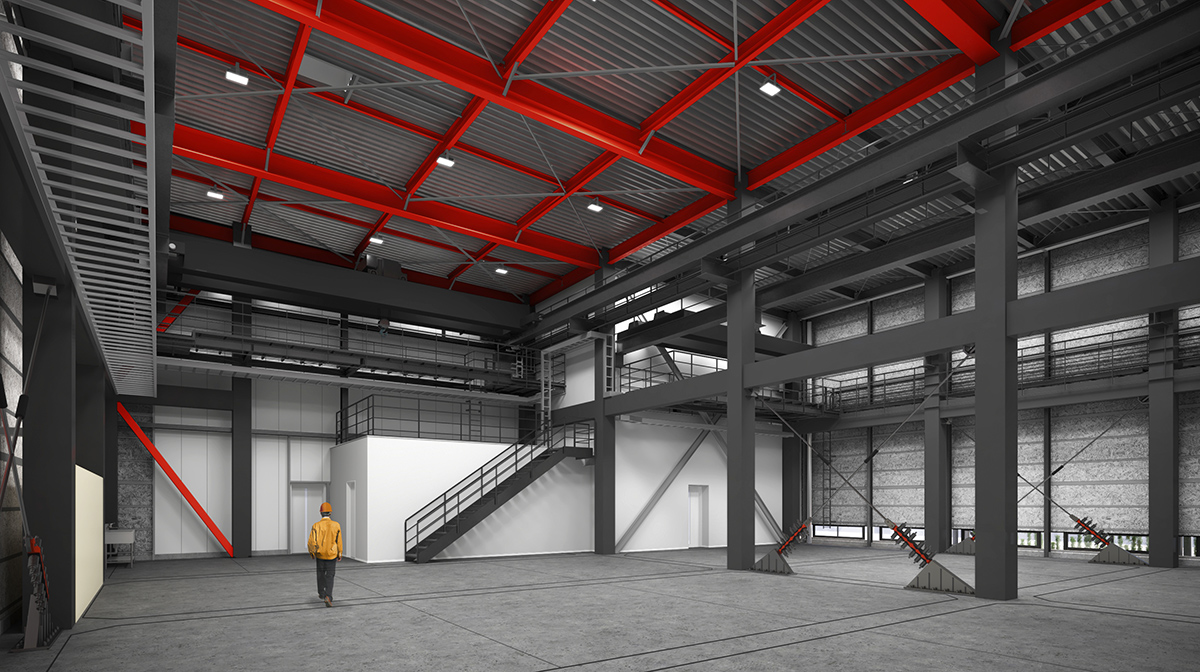

Red-painted sections indicate reused steel beams

Rather than restoring the same structure using old materials, this unprecedented initiative gives new life to those materials by repurposing them in a completely different building. While there are examples of reusing timber from demolished wooden buildings, there have been no previous cases in Japan of reusing steel or concrete structural components from demolished buildings as the structural framework of a new building. Through this project, Obayashi aims to advance the development of technologies suited for such reuse.

-

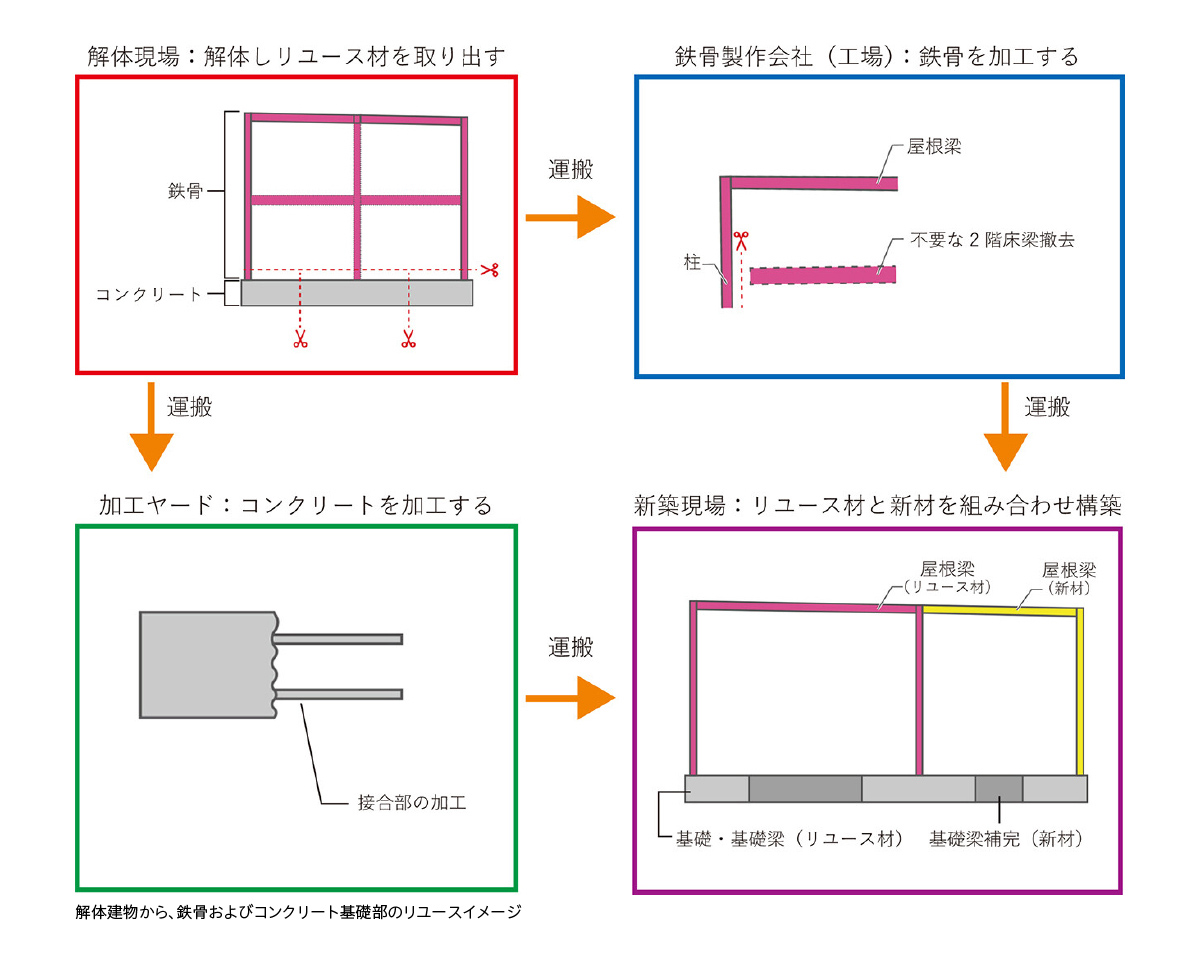

Processing and joining steel and concrete structural components with new materials

Steel components—including columns, beams, and braces—from the demolished test building were removed, cut, and modified to match the design of the new structure, then reused as part of the new structural frame. Concrete structural elements such as foundations, foundation beams, girders, and floor slabs were also cut to fit the floor plan of the new building. Their joints were processed to allow on-site connection with new materials, enabling their reuse as part of the new structure.

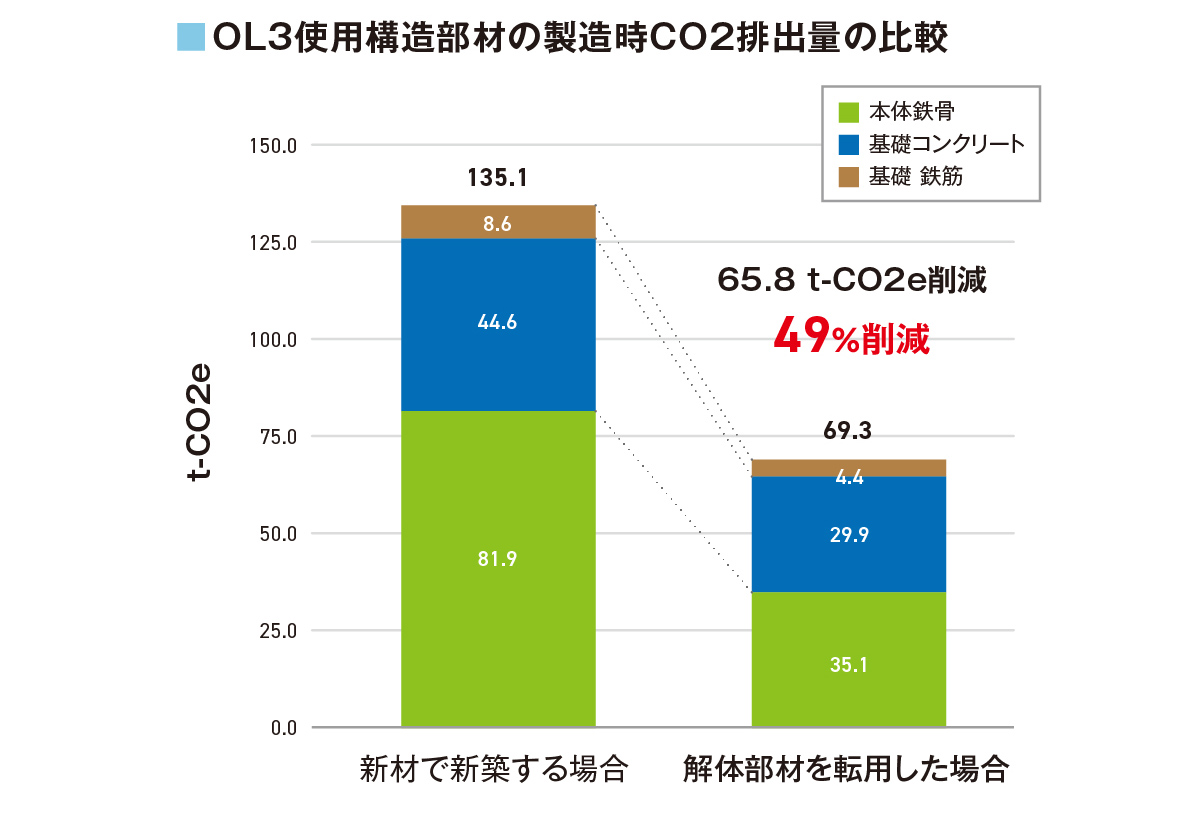

Approximately 49% reduction in CO2 emissions compared to using all-new materials

Comparison of CO2 emissions from structural component production in Open Lab 3 (OL3)

In the new building, 57% of the steel and 33% of the concrete structural components are reused materials from the demolished structure. As a result, CO2 emissions associated with the production of structural components are expected to be reduced by approximately 49% compared to using entirely new materials.

Reusing materials from EXPO 2025 OSAKA, KANSAI, JAPAN pavilions

Materials from pavilions that will be dismantled after the EXPO 2025 OSAKA, KANSAI, JAPAN will be reused. These include interior materials such as tile carpets; exterior and landscaping materials such as paving blocks, grating, and decking; electrical equipment such as lighting fixtures, speakers, and outlet switches; HVAC equipment such as ventilation fans and diffusers; and plumbing and safety equipment such as faucets, sanitary ceramics, and fire prevention systems.

Use of diverse recycled building materials

(From left) CleanCrete N, CO2-fixing paint, Lignin-Crete, Alpha Timber, Indoor Greening

Clean-Crete N (precast exterior panels):

Achieves net-zero or negative CO2 emissions during production (carbon negative).

Cement made with recycled materials such as ground granulated blast-furnace slag and cement-based waste is used in the precast exterior panels.

CO2-fixing paint (interior coating material):

Paint made with recycled scallop shells as a raw material.

Lignin-Crete (stair treads):

Powdered lignin, a byproduct of woody biomass waste, is used as a substitute for sand in the concrete mix.

Reuse of felled trees:

Trees cut down during new construction are reused as exterior or interior materials.

Green steel (structural rebar):

Recycled steel produced using a CO2-reducing process is used for reinforcement bars.