Please note that some content is only available in Japanese

One-Bind Cross

Faster, higher-quality reinforcement of tunnel linings

POINT

-

A rapid reinforcement method that enables early reopening to traffic

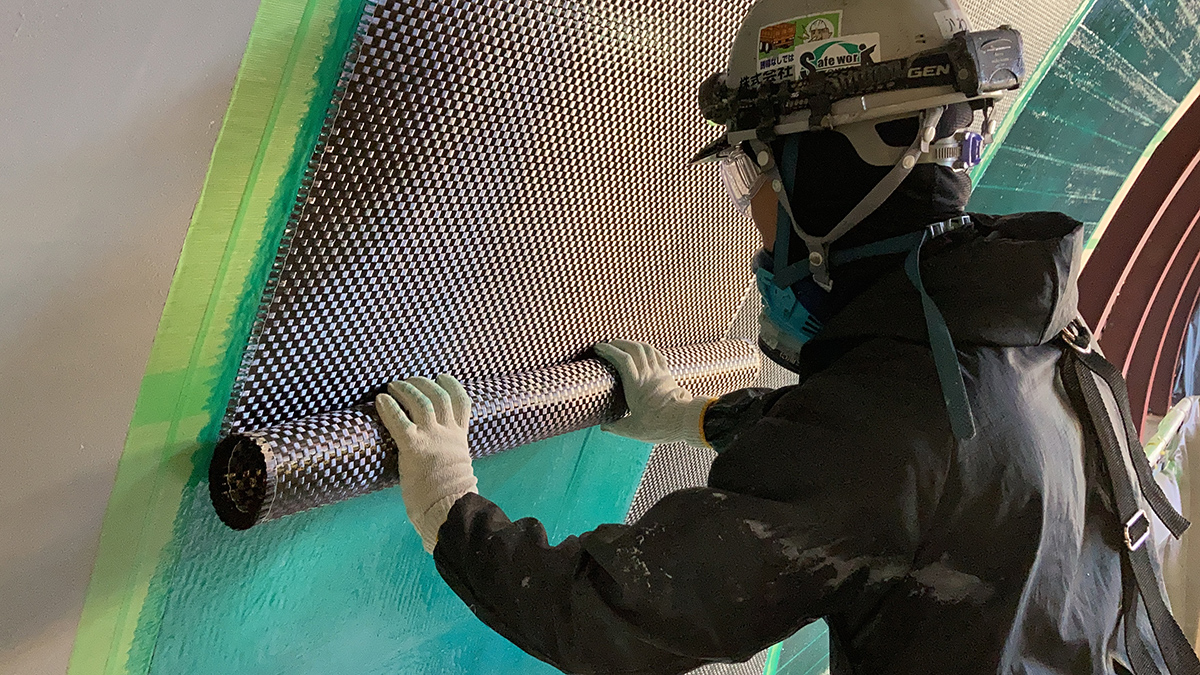

This is a tunnel lining reinforcement method that uses high-fiber areal weight, bidirectional carbon fiber sheets. Since reinforcement can be completed with just one layer of sheet, the work process is shortened. The use of large-format sheets (1 meter wide) also improves installation efficiency. Thanks to the special manufacturing method of the carbon fiber sheets, a single layer provides strength equivalent to two conventional layers, eliminating issues such as poor adhesion between layers.

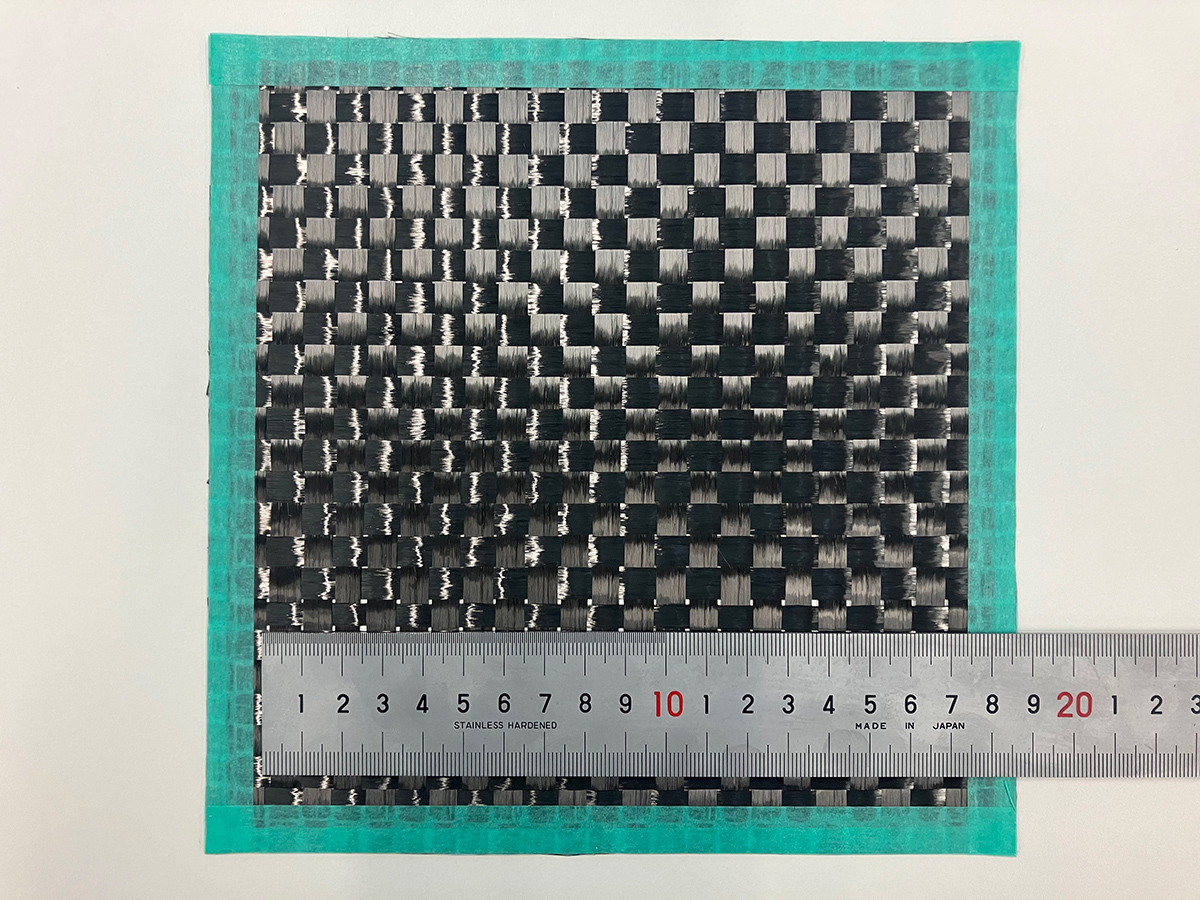

High-fiber areal weight, bidirectional carbon fiber sheet

A high-fiber areal weight, bidirectional carbon fiber sheet with a fiber areal weight of 200 g/m² in both warp and weft directions, and high strength—tensile strength of 2,900 N/mm² or more, and a static elastic modulus of 245 ± 36 kN/mm².

This method complies with the “materials for preventing spalling exceeding small fragments” criteria in the NEXCO Tunnel Construction Management Manual (R5.7).Truck-mounted system work platform “Flap Lift”

Flap Lift provides a wide work platform that can cover half the tunnel cross-section (10.5 m in length). The platform can be easily deployed and retracted on the bed of a large truck, making it ideal for projects involving one-lane traffic control and daily transport in and out of the site. The hydraulic system allows the platform to be positioned at the optimal height and angle to follow the tunnel’s arched shape. Workers can move freely across the wide platform, significantly improving work efficiency. When combined with the One-Bind Cross, it can further greatly reduce times of traffic restriction.

“Pitant” environmental control system for construction sites

Pitant is a system that maintains optimal working conditions even in the high-humidity environments inside tunnels. Its tent-like structure fits snugly against the tunnel lining, blocking outside air from entering the workspace. By circulating air using climate control equipment, it maintains the temperature and humidity required for proper construction conditions.

It helps prevent curing defects in the epoxy resin used with One-Bind Cross, ensuring quality and preventing schedule delays caused by work stoppages or rework.