Please note that some content is only available in Japanese

Compact Invert

Rapid invert construction using precast components

POINT

-

Contributing to more efficient tunnel renovation work

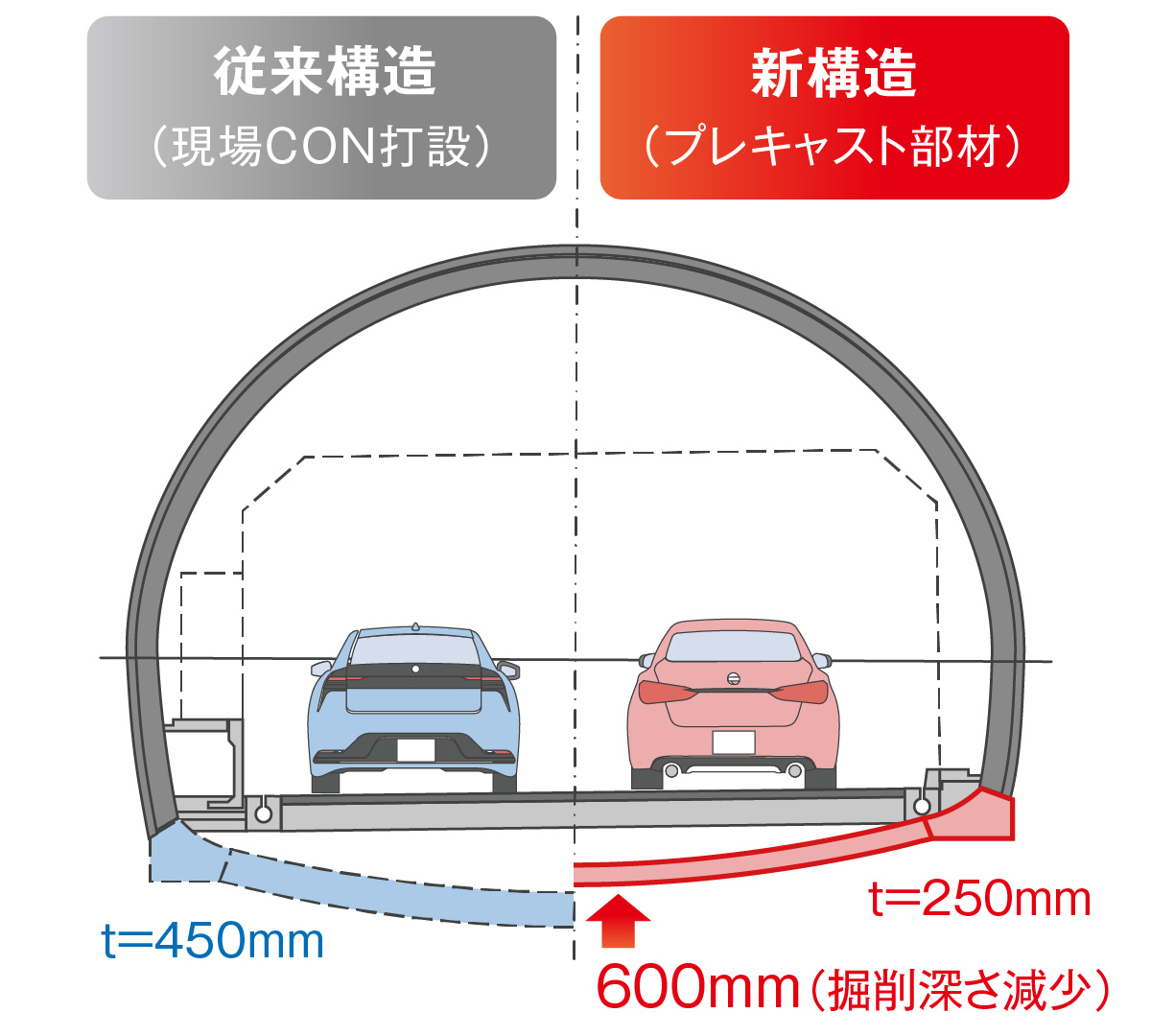

This is a rapid construction method for invert concrete in tunnel renovation projects. Without changing the curvature of the invert, the structure uses thin, high-strength reinforced concrete (RC) components, installed at a shallower depth to avoid interfering with utilities.

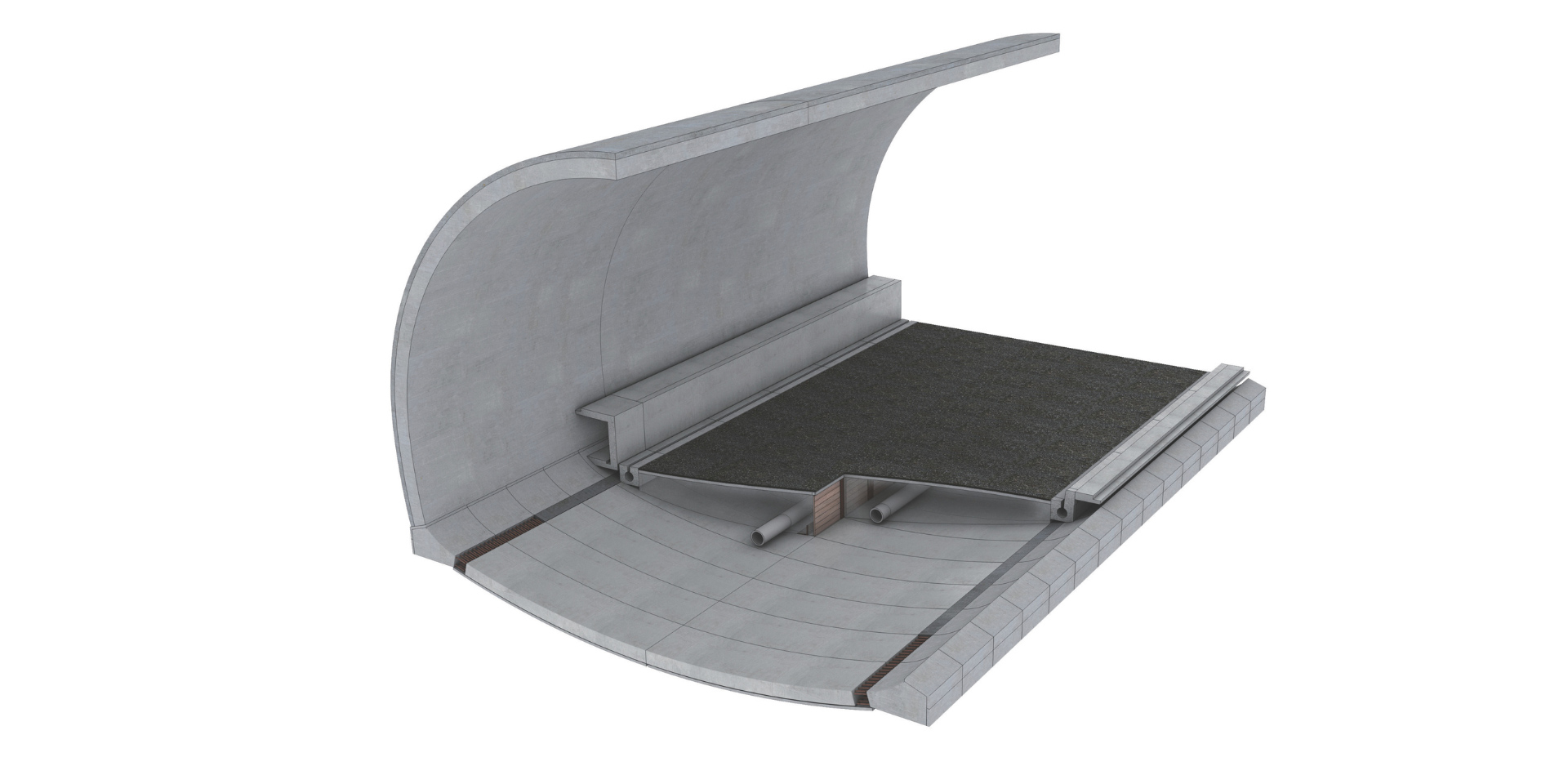

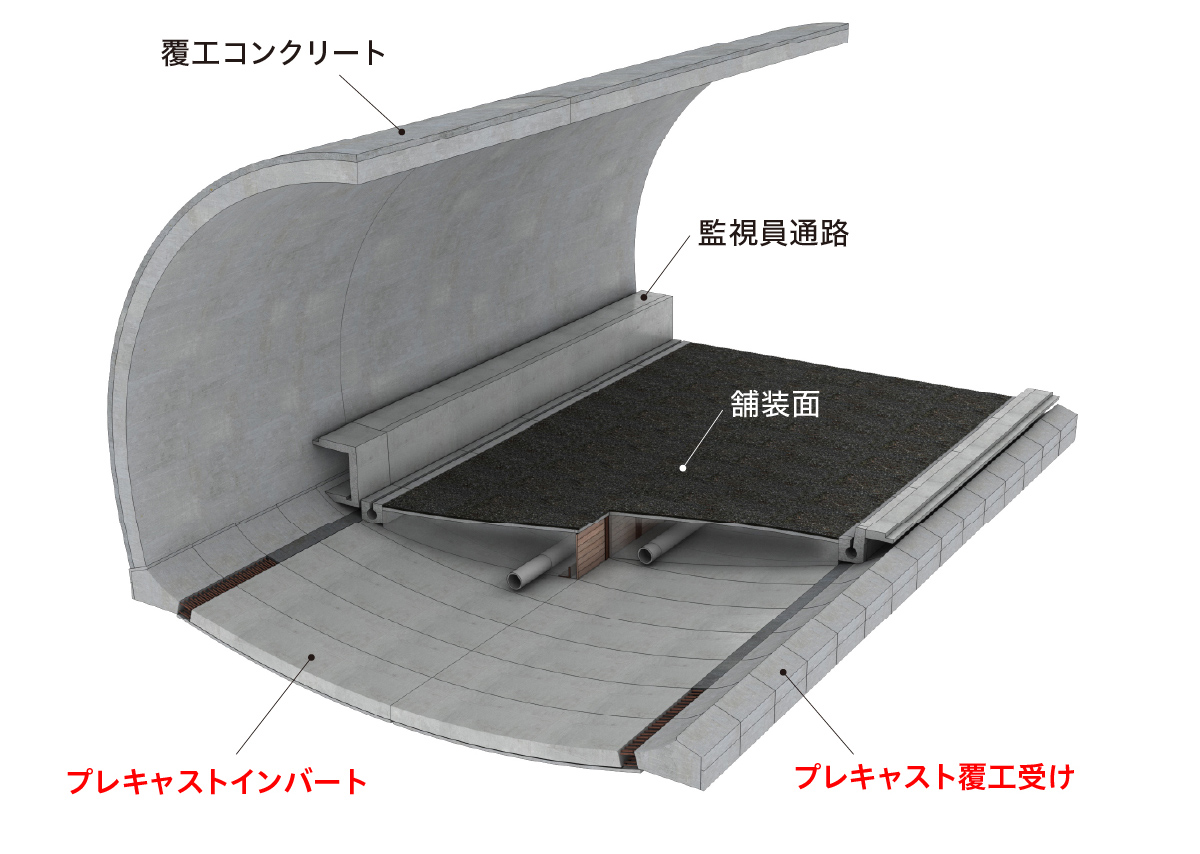

This new invert design greatly reduces on-site construction volume and quickly delivers reinforcement effects after installation, eliminating the need for invert support structures.Applying precast components to the invert

The invert can be designed with the necessary cross-sectional performance to resist subgrade heaving. By using reinforced concrete, load-bearing capacity is improved. Both the invert and the lining support sections are made precast, which helps to streamline the connection process between the invert and the tunnel lining.

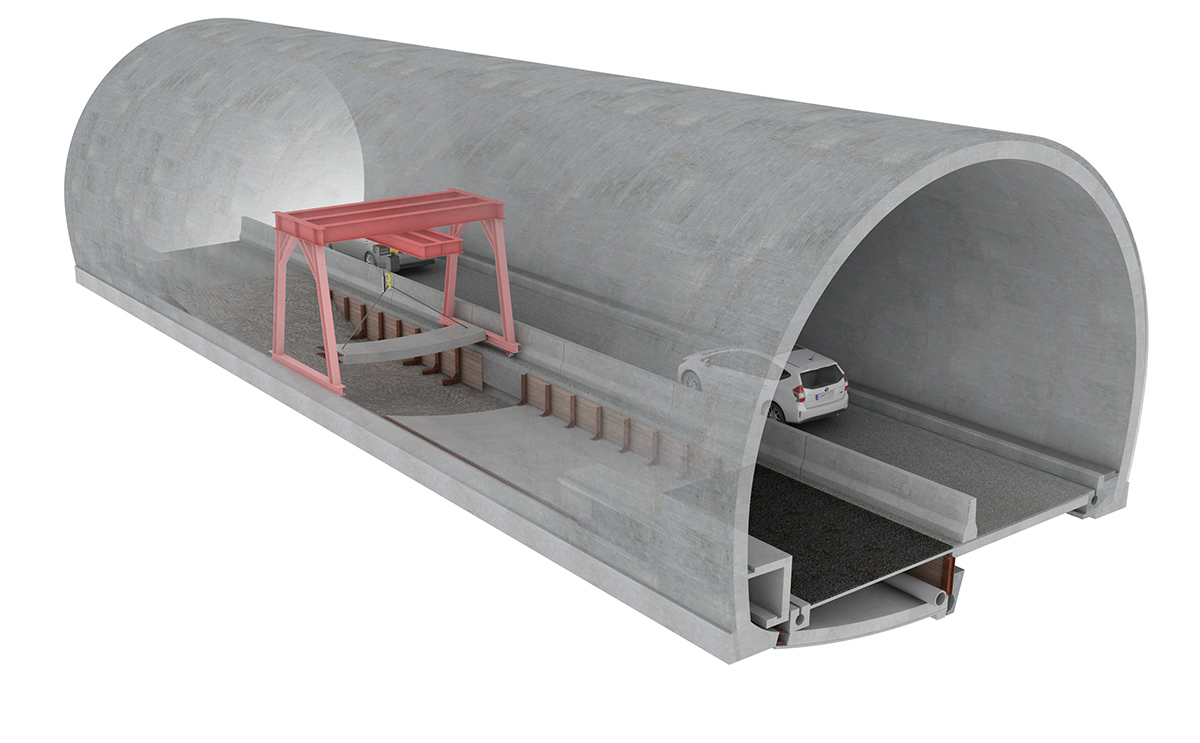

Supports sectionalized construction

The precast units can be designed for center-split installation, making it easy to perform half-section construction under single-lane traffic restrictions. Since the excavation depth is shallow, there is no need to install retaining piles at the tunnel centerline, eliminating neighboring work between heavy machinery and active traffic lanes—improving overall safety.