Please note that some content is only available in Japanese

PC Wider

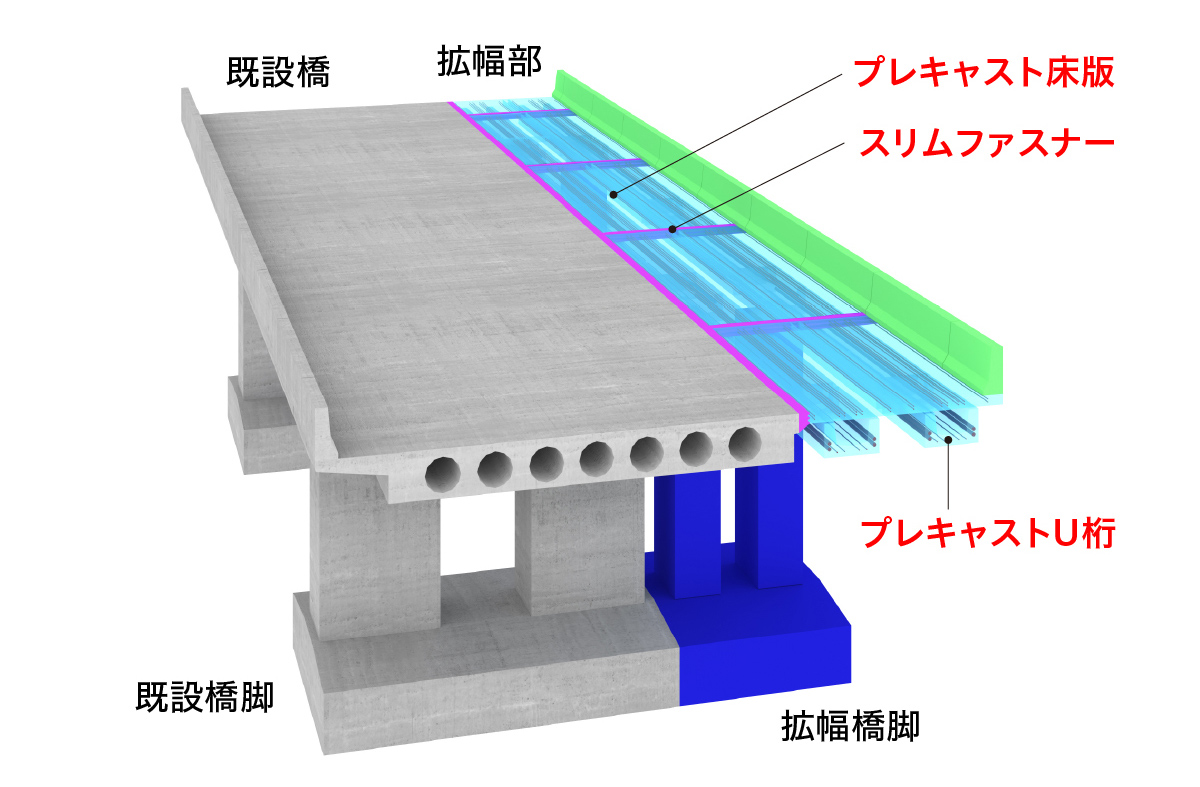

Bridge widening using PCa-U girders for concrete bridges

POINT

-

Reducing the weight of the widened section by 60%

PC Wider overview video

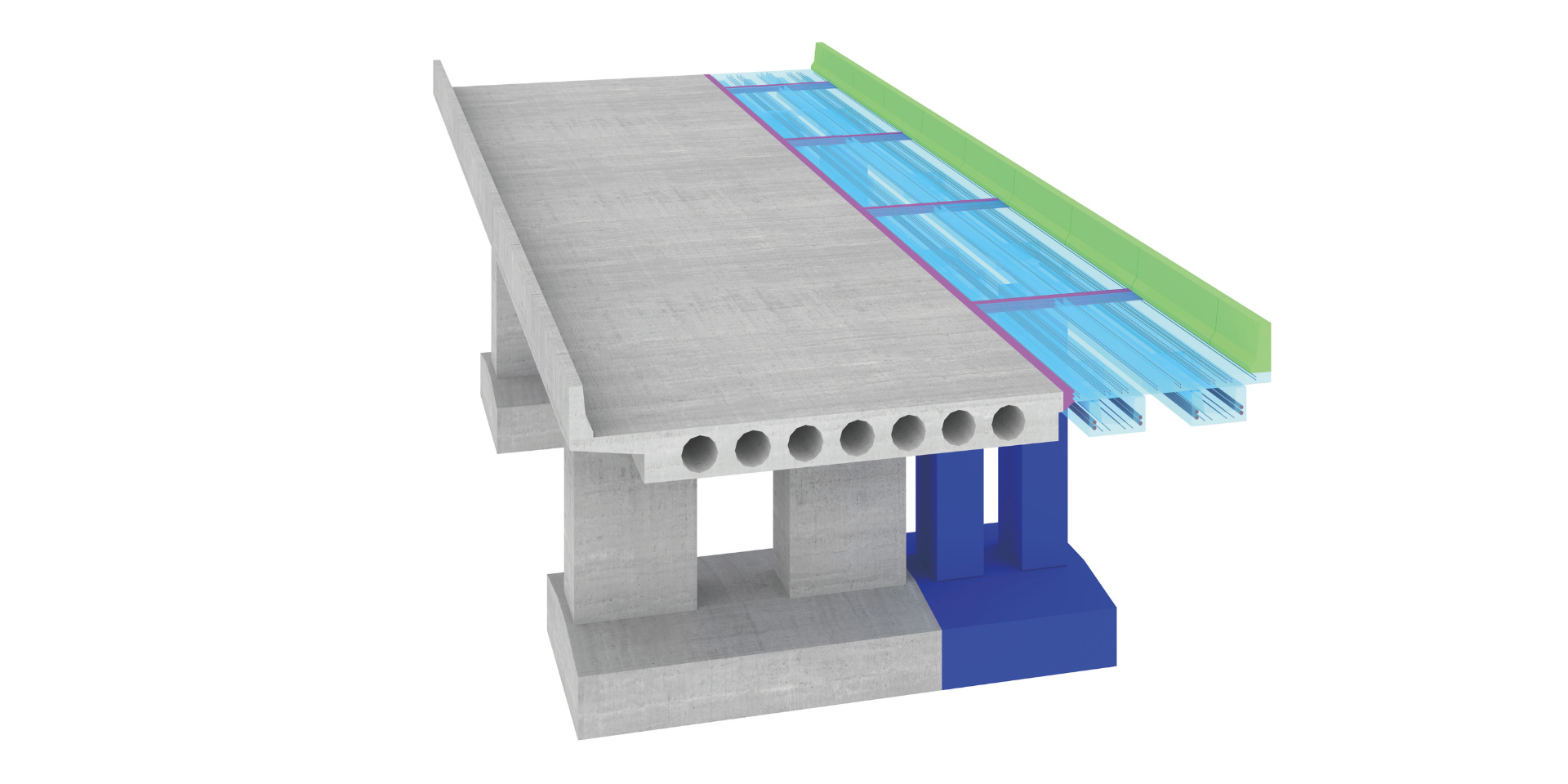

The design separates the use of PCa-U girders and PCa deck panels, joining only the U-girder sections using post-tensioned PC steel tendons. In addition, by applying SLIM FASTENER at the deck joints, the quantity of PC steel and concrete used in the widened superstructure is reduced, bringing the total weight of the girders and deck down to approximately 60% of that in conventional methods. The widening structure is achieved through the effective use of precast components and optimized placement of both pre-tensioned PC wires and post-tensioned PC tendons.

-

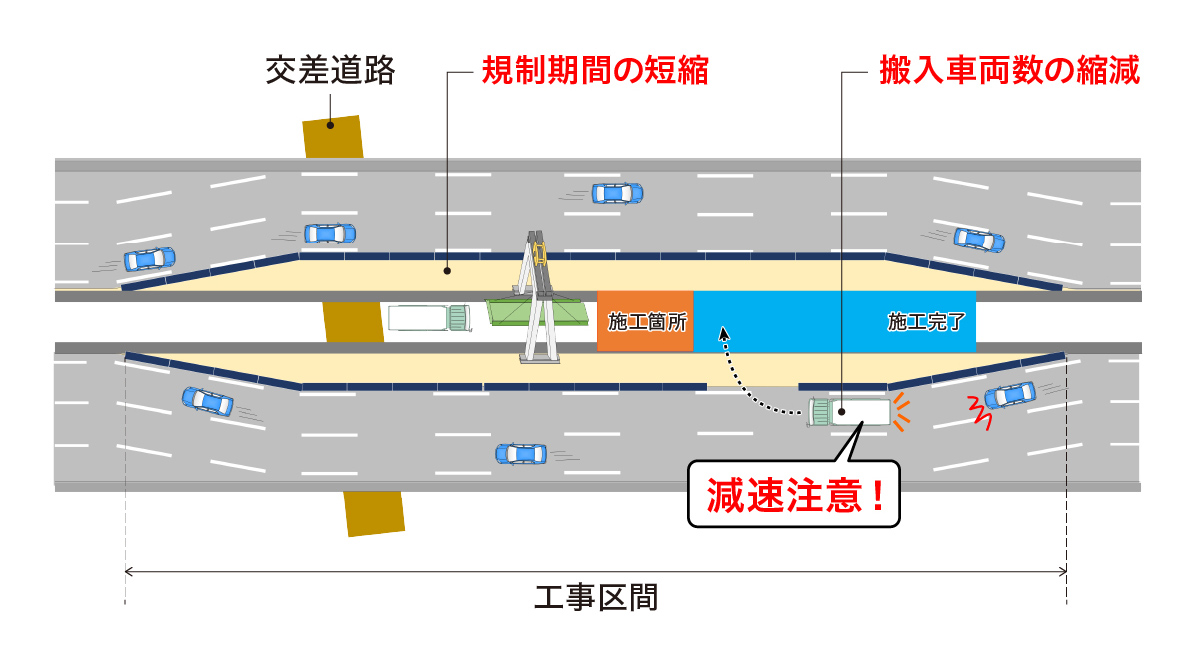

Reducing traffic restriction periods by 30%

In conventional methods, cast-in-place concrete for the widened section (in the case of PC bridges) requires a six-month curing period before the second-stage deck slab at the joint can be constructed. By using precast components, it becomes possible to secure sufficient curing time in advance, reducing the effects of creep and drying shrinkage. After curing, the precast segments are installed on-site and the joint sections completed in sequence, allowing the traffic restriction period to be shortened to just 30% of that required by conventional methods.

High versatility

The widening structure can now be implemented at the same girder height as the existing bridge, even for bridges with low girder depths. It is compatible with a variety of girder cross-sections, including T-girders and box girders, and can be applied to various structural types such as simple-span, continuous-span, and composite girders. In addition to widening on the shoulder side, it can also be used for median-side widening, enabling applications to bridge types that were previously difficult to adapt.