Please note that some content is only available in Japanese

Fireproof Coating Spray Robot

Achieve the same productivity and spraying quality as skilled-workers

POINT

-

Spraying in various positions using a robotic arm

Video of the fireproofing spray robot

To protect steel frames in steel-structure buildings from fire damage, Obayashi has automated the fireproof coating spraying application process.

The robot was specifically designed and developed to efficiently spray beams in office buildings. Both the spraying productivity and quality now reach the level of skilled workers. -

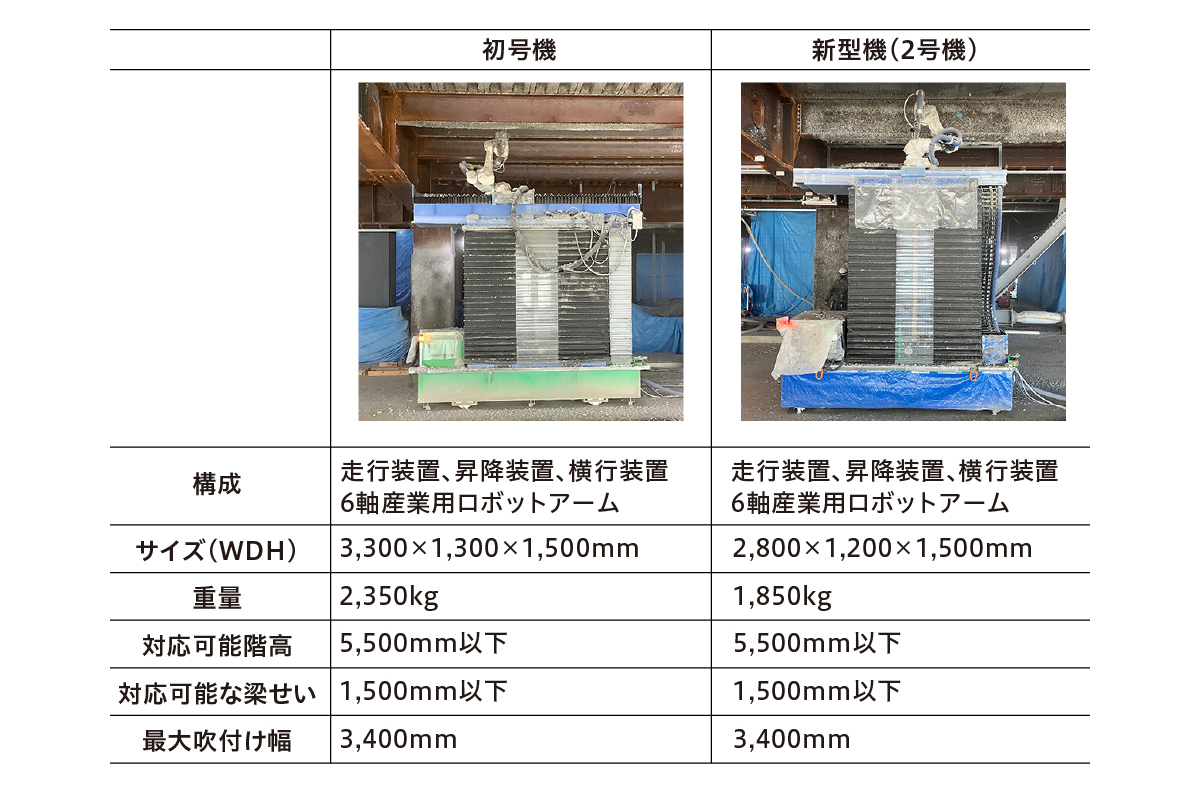

Second-generation robots are more compact and lightweight

Comparison chart of the first-generation (left) and the second-generation (right)

The second generation is 500mm smaller in width and 500kg lighter. The smaller size makes it easier to operate on construction sites and makes it easier to get on and off construction elevators.

-

Stabilizing quality with highly accurate autonomous movement and beam recognition function

Autonomous movement in action

We devised a measurement method that enables stable positioning even in dusty environments, achieving highly accurate positioning of the robot. By measuring the beams before spraying, the relative position and angle between the beams and the robot can be calculated, and the spraying paths of the robot can be corrected to ensure spraying according to the design values, resulting in stable spraying quality.