Please note that some content is only available in Japanese

Clean-Crete Segments

Environmentally friendly segments with significantly reduced CO2 emissions

POINT

-

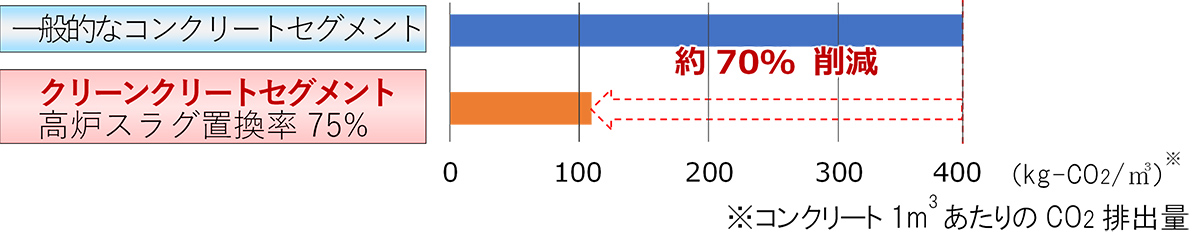

Approximately 70% reduction in CO2 emissions during segment production

Clean-Crete Segments

By using Clean-Crete mixed with ground granulated blast furnace slag in the concrete for RC (reinforced concrete) segments used in shield tunnel lining, CO2 emissions can be significantly reduced compared to using conventional concrete. This results in a roughly 70% reduction in CO2 emissions during segment production. For example, in a shield tunneling project with a segment outer diameter of 10-meter and a 2-kilometer length reduces approximately 7,560 tons of CO2.

-

Ground granulated blast furnace slag

-

CO2 emission reduction effect

-

Improved durability with quality and cost performance equal to or better than conventional segments

Strength confirmed through full-scale testing

Using ground granulated blast-furnace slag results in denser concrete, which slows chloride penetration and enhances the durability of the reinforcing steel against salt damage. Full-scale testing has confirmed that the segments offer hardening characteristics and compressive strength equal to or greater than those of standard reinforced concrete segments.

Since they can be produced using existing plants, the manufacturing cost is comparable to that of conventional concrete segments.