Please note that some content is only available in Japanese

Carbon-Neutral Backfill Grouting Material

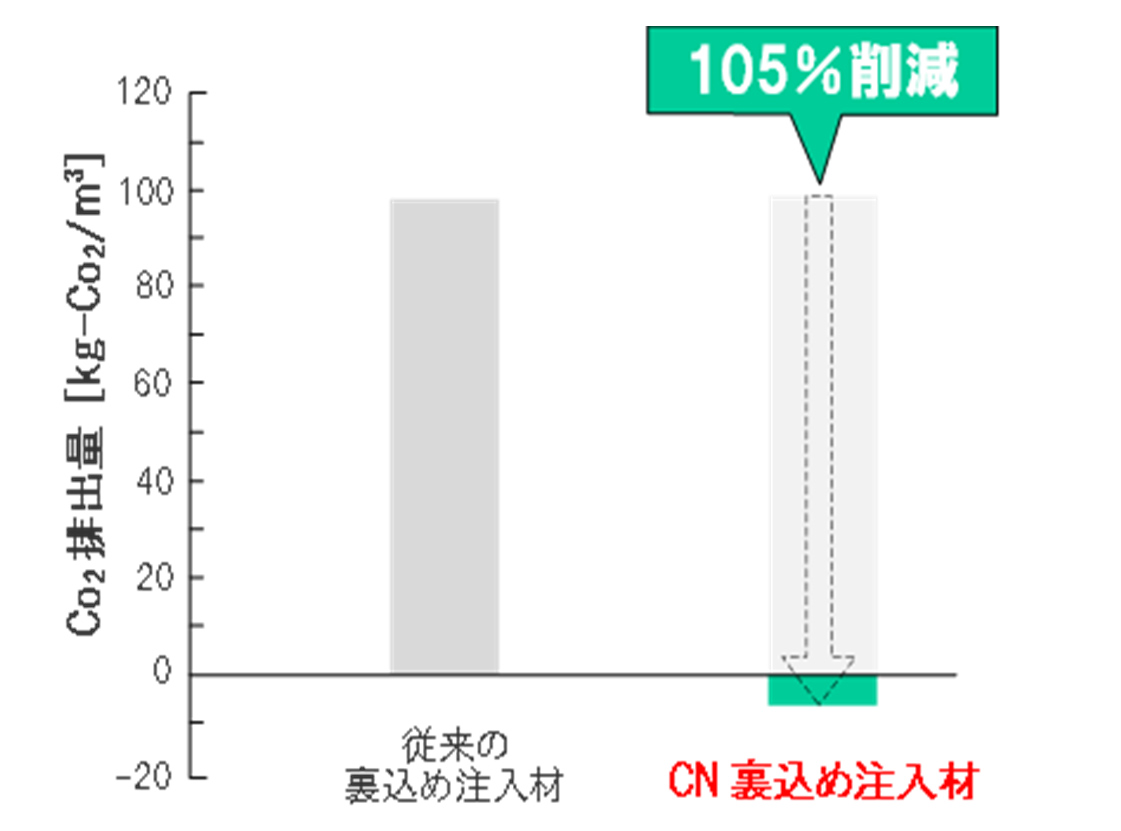

Reducing CO2 emissions during shield tunnel construction to net-zero or below

POINT

-

Same flowability and compressive strength as conventional backfill grout

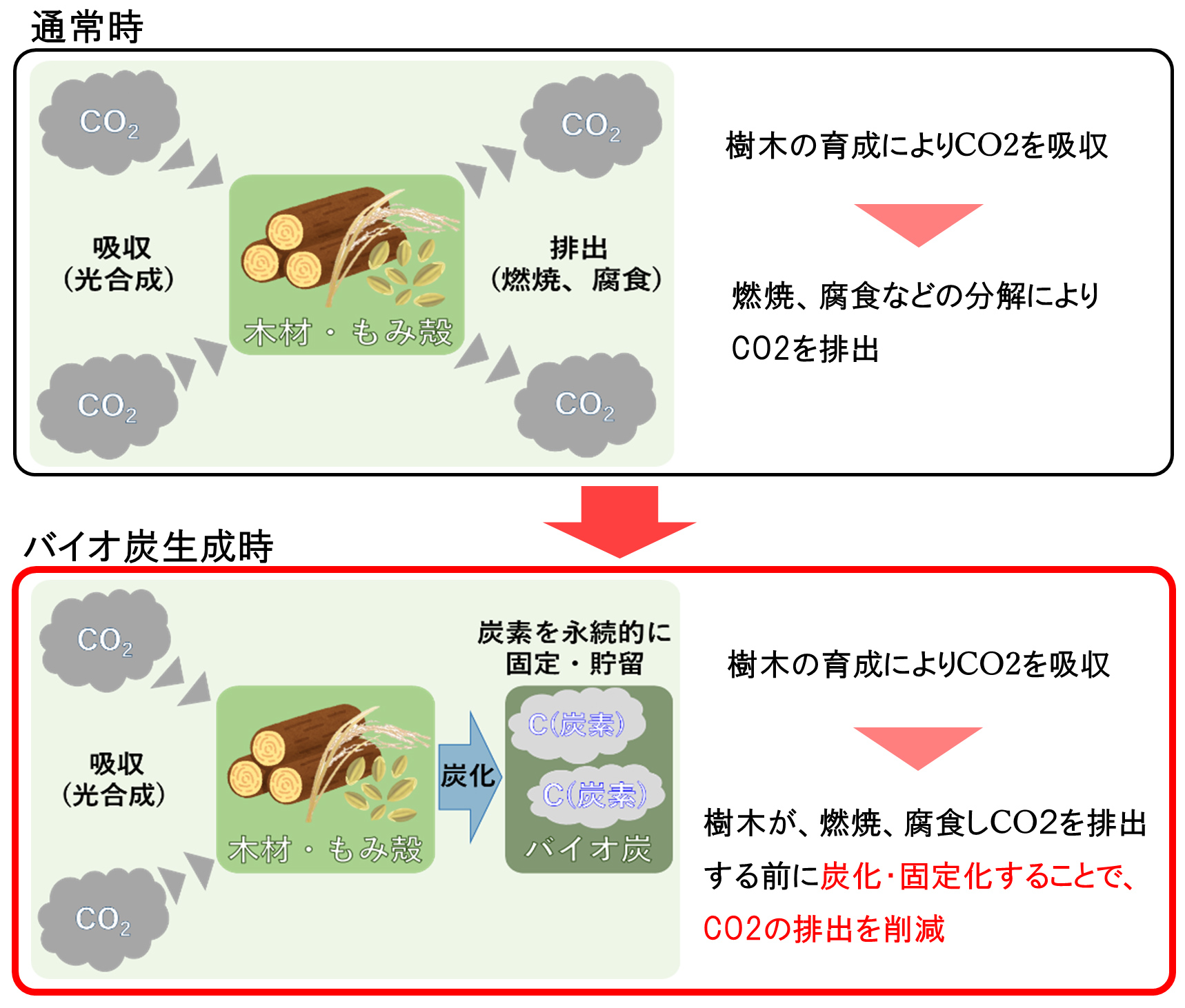

In shield tunneling, the backfill grout used to fill the void between the assembled segments and the surrounding ground typically involves cement-based solidifying materials, which emit CO2 during production. By replacing these with biochar—capable of capturing and storing carbon—the system can achieve a net CO2 reduction of 105%. For example, in a shield tunnel with a 10-meter segment outer diameter of 10-meter and a length of 2 kilometers, this would reduce CO2 emissions by approximately 910 tons compared to conventional materials. At the same time, it maintains the required performance, including flowability and compressive strength equivalent to standard backfill grout.

Wood-derived biochar

Carbon neutral backfill grouting material

CO2 emission reduction effect

Preventing material dispersion during mixing to maintain work environment

The biochar is pre-mixed with bentonite-based materials before being delivered to the site. This prevents material dispersibility during mixing while also preventing particles from spreading into the surrounding area.

Construction can proceed using existing equipment and the same work cycle as conventional methods.