Please note that some content is only available in Japanese

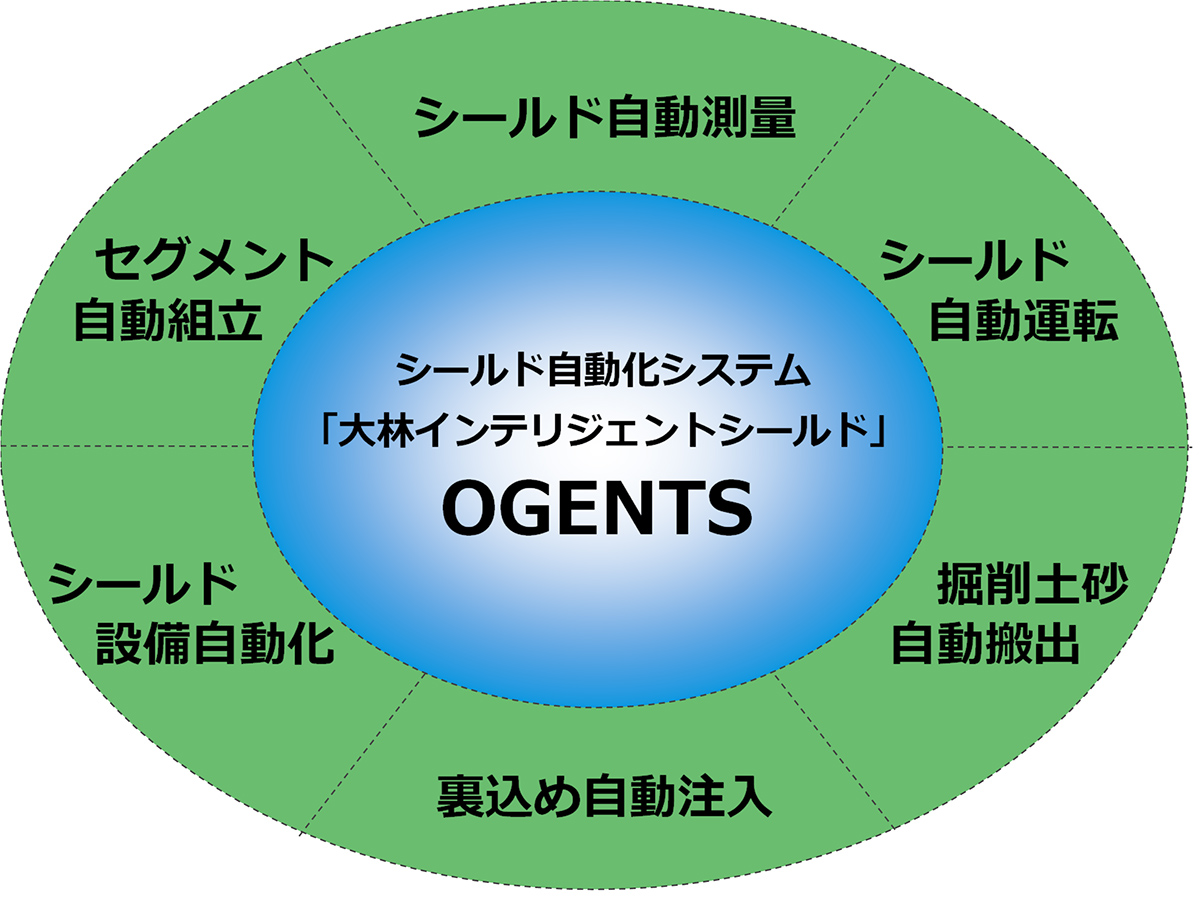

OGENTS

Automating various shield tunneling operations

POINT

-

Automating shield tunneling by integrating six types of work processes

OGENTS (Obayashi Intelligent Shield)

Among construction methods, shield tunneling is relatively advanced in terms of mechanization and automation; however, it still requires a large number of skilled workers. To address the growing labor shortage caused by population decline and aging, OGENTS integrates automation technologies for six key shield tunneling operations to achieve full automation of the entire process. This enables both labor savings and improved construction quality.

-

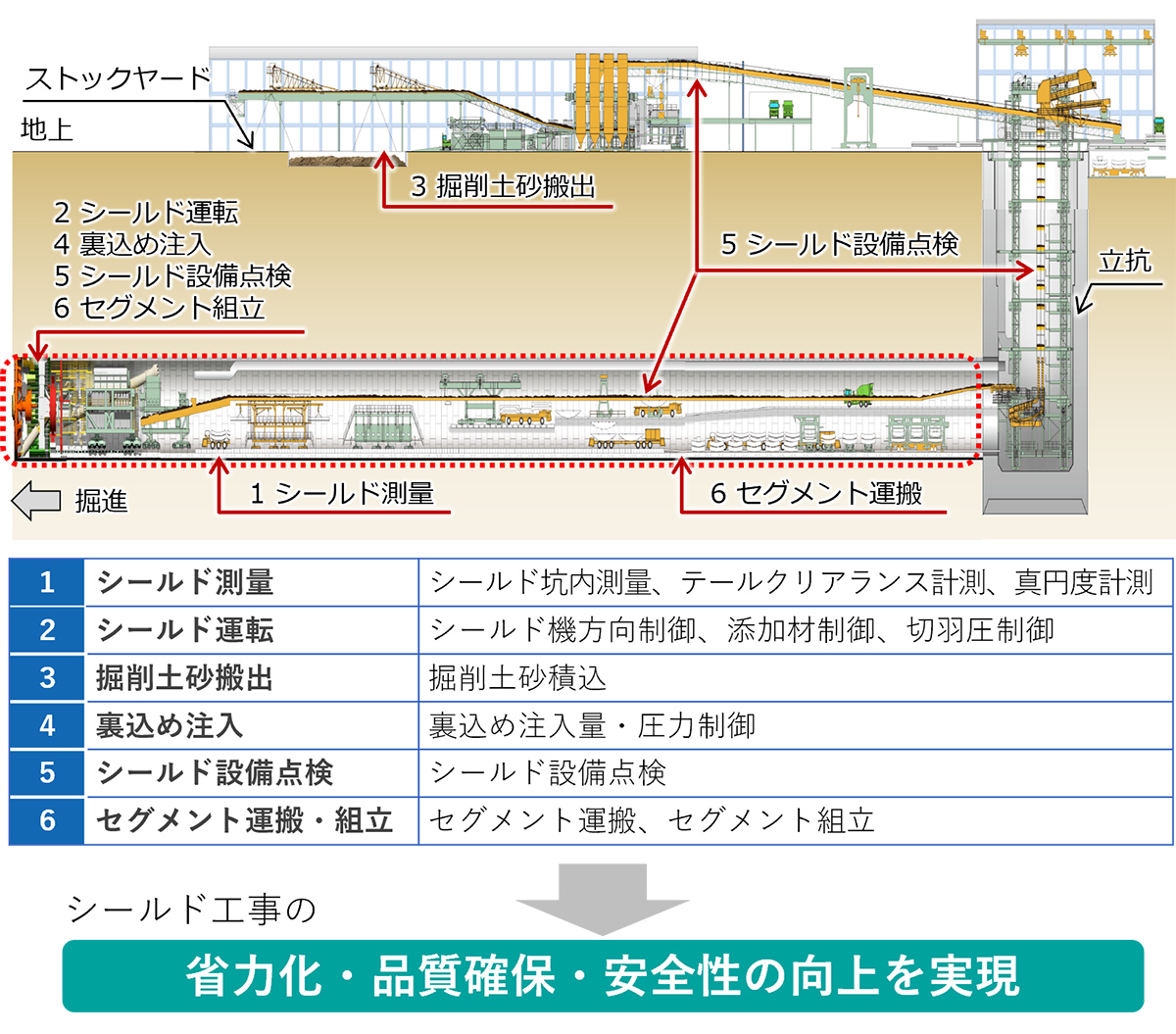

Six key shield tunneling operations

-

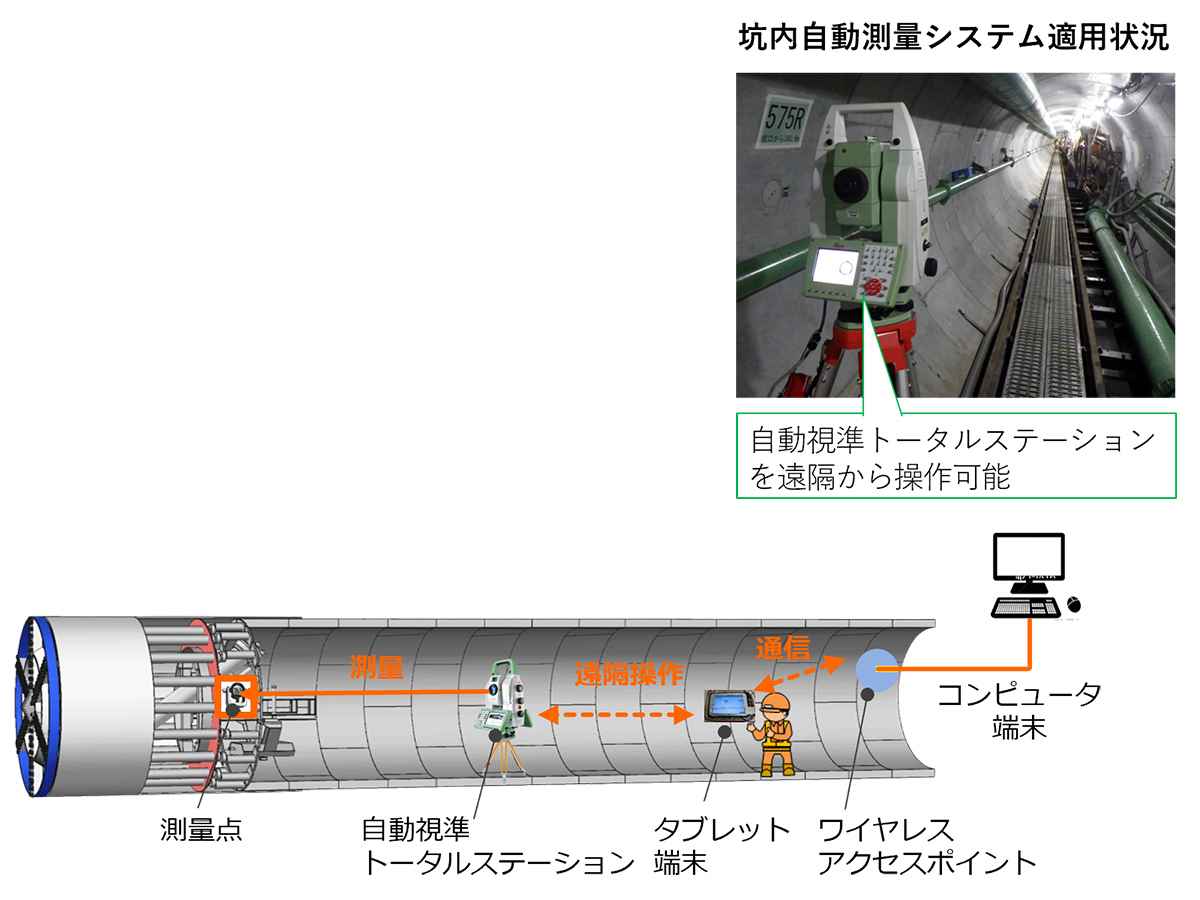

Labor-saving and efficiency improvements through automated surveying

OGENTS/SURVEY enables remote operation of a total station via a tablet device, eliminating the need for an assistant to reposition the prism—previously required for each measurement—allowing one person to complete the survey alone. The total station is equipped with an automatic prism detection and targeting function, and survey data is automatically transmitted, reducing work time by 30%.

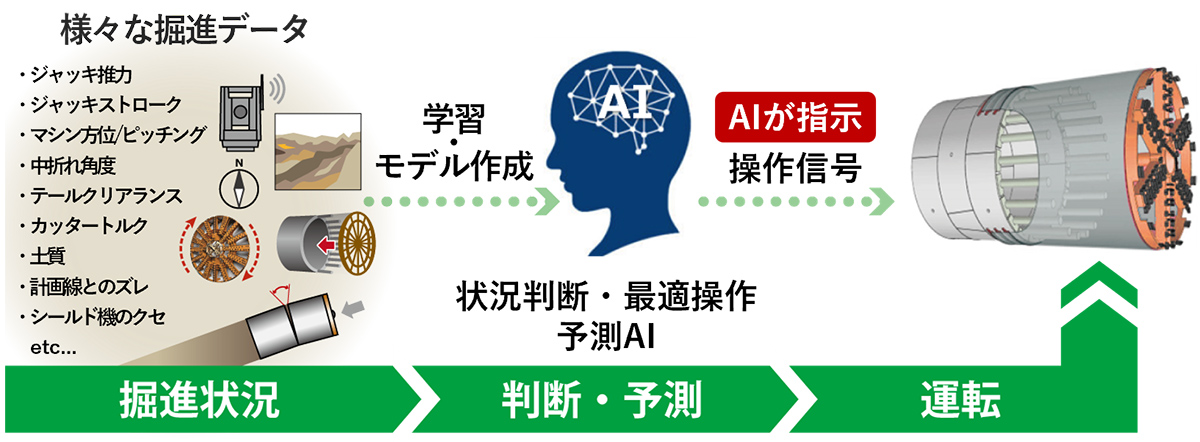

Automating shield direction control with AI

OGENTS/DRIVE uses AI to control shield direction by selecting jacks based on learned operations from skilled operators. The AI automated driving has been applied at several sites, and its accuracy has been verified.

Unmanned operation through AI-driven automatic loading of excavated soil

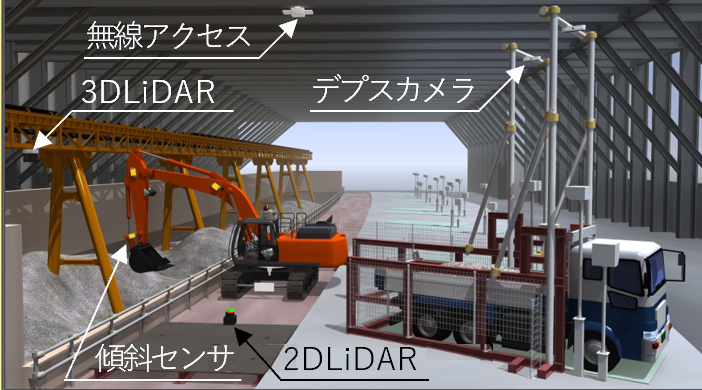

Autonomous Backhoe Operation System

The Autonomous Backhoe Operation System uses data from measurement devices such as 3D LiDAR installed in the soil stockyard to allow AI to determine where to excavate and operate the backhoe automatically. The AI also identifies the location and weight of the soil to be loaded onto dump trucks.

Automatic control of backfill grout volume and pressure

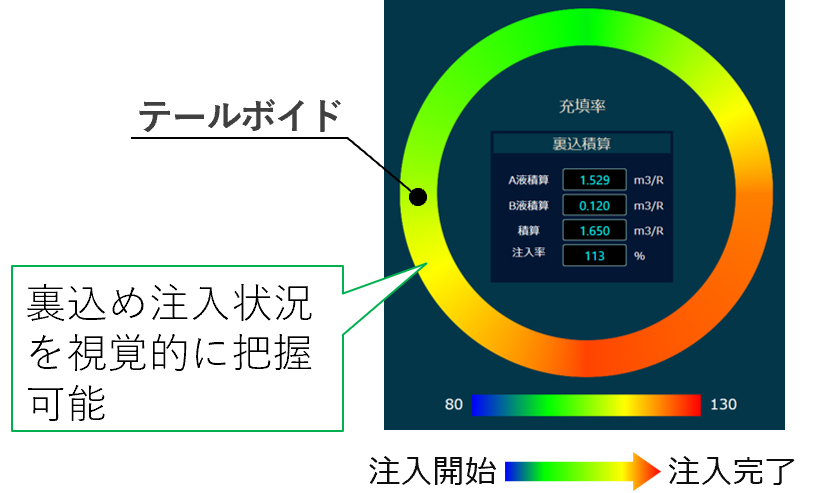

Backfill grouting management interface

The “Automatic Backfill Grouting Management System” adjusts the volume and pressure of grout injection automatically, based on the excavation speed and size of the tail void. This ensures reliable backfilling and helps prevent surface and ground deformation.

Preventing equipment failure through preventive maintenance

Shield equipment integrated management screen

Data from each individual piece of equipment—monitored for operational health—is consolidated into a single interface. If signs of abnormality are detected, a warning is displayed.The Shield Equipment Integrated Management System is an automated inspection technology that collects operating data from each piece of equipment and detects signs of abnormalities to issue warnings. Preventive maintenance of shield equipment helps avoid potential failures before they occur.

Preventing accidents through unmanned segment transport and remote assembly

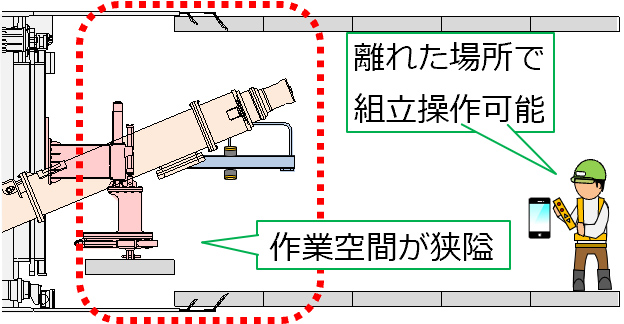

Segment Remote Assembly System

Segment transport from the surface stockyard to the tunnel face is automated, and segments are assembled via remote operation. This helps prevent accidents such as flying or falling objects and collisions during transport, as well as falls or entrapment during assembly.