Please note that some content is only available in Japanese

Scallop Seal / Scallop Paint

Sealant and paint made with powdered scallop shells

POINT

-

Effective use of discarded scallop shells

Scallop Seal / Scallop Paint

A biomass filler made from crushed scallop shells is used to replace calcium carbonate in sealants for joints and seams, as well as in paints.

Scallops absorb and fix CO2 from seawater in their shells as they grow, reducing CO2 emissions during manufacturing. Since the main component of scallop shells is calcium carbonate, they are flame-resistant and hard to decompose, making incineration difficult and disposal a challenge. By crushing and reusing them as biomass filler, waste can be reduced. The biomass-filled sealant Scallop Seal and paint Scallop Paint deliver performance equal to or better than conventional products. -

Equivalent or better performance with reduced CO2 emissions during manufacturing

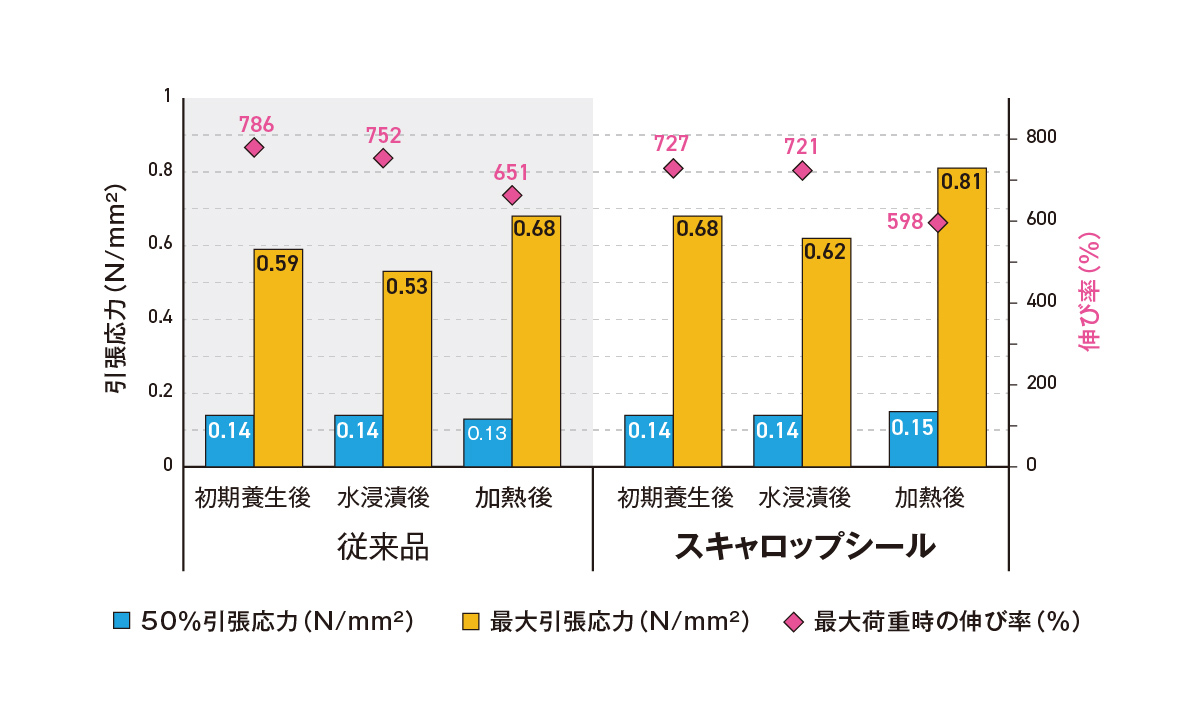

Tensile adhesion of Scallop Paint

Conventional sealants typically contain calcium carbonate derived from limestone, which emits approximately 0.09 kg-CO2 per kg during production. In contrast, scallop shells emit -0.44 kg-CO2 per kg, meaning they effectively reduce CO2 when reused as biomass filler. By incorporating scallop shell filler, the CO2 emissions associated with sealant production can be significantly lowered. Scallop Seal achieves comparable cost and performance—such as water and heat resistance—to standard two-component modified silicone sealants widely used in the industry. It also bonds well with finishing paints, and due to the higher kinematic viscosity provided by the biomass filler, it restricts sagging, improving workability.

-

Finish materials used for the Women’s Pavilion at Expo 2025 Osaka, Kansai, Japan

The Women’s Pavilion in collaboration with Cartier ©Cartier

Scallop Seal has been applied on-site in the construction of the Women’s Pavilion in collaboration with Cartier for Expo 2025 Osaka, Kansai, Japan a project undertaken by Obayashi Corporation.