Please note that some content is only available in Japanese

Chapter 03 CREATION Realizing a Decarbonized Society and Creating New Social Value

Explore the many new value creation initiatives the Obayashi Group is making

toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.

Corporation

Obayashi Corporation×

Traditional Architecture

and Living Heritage

- What We Seek to Preserve is “The Story” that Buildings Share with People and Cities

- Why are we so drawn to historic buildings? It’s because they embody the stories of people and cities passed down through time. At Obayashi Corporation, we approach the preservation and renovation of historic structures from two perspectives: the continuation of architectural styles and the carrying of memories. For example, at the World Heritage site of Hiraizumi, we preserved the appearance of the Hondo Main Hall of Chuson-ji Temple as it has been since the Heian period. In Kyoto’s Gion district, we revitalized the Yasaka Kaikan as a place that connects with the memory of the city. Through these and many other projects, we have accumulated extensive knowledge that we share across the organization. Preserving a building means passing on its story to the future—and that, we believe, is our mission at Obayashi Corporation.

Chuson-ji Temple

Preserving a Legacy from the Heian Period in Its Unchanging Form for the Future

The top priority in the seismic reinforcement of the Chuson-ji Main Hall was to preserve the exact appearance of the Heian-style structure that was reconstructed during the Meiji era. This meant maintaining not only the exterior but also the usability of the interior without alteration. Within those constraints, we pursued the highest level of seismic performance, repeatedly refining our approach and taking on the challenge of integrating traditional aesthetics with modern technology. With a deep sense of pride and responsibility in protecting this World Heritage Site—an irreplaceable treasure of humanity—we enhanced the structure’s seismic resilience using Obayashi’s proprietary technology while ensuring design flexibility. Our hope is that this historic building will continue to welcome visitors in its enduring form and carry its story forward for another thousand years.

General Manager, Traditional Architecture and Heritage Project Team Marketing Division, Obayashi Corporation Shinji Yamazaki

Architecture

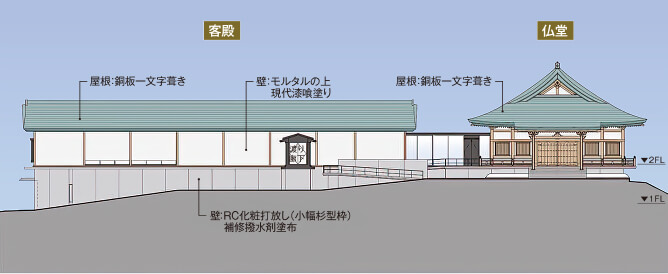

Continuation of Architectural Style with Modern Technology New Construction of Koshoin

- A New Buddhist Hall and Guest Pavilion

- Within the precinct of the Chuson-ji Main Hall, we constructed the Buddhist hall Koshoin and a new guest pavilion to receive distinguished visitors from Japan and abroad. The project required careful planning to preserve the historical remains, such as foundation postholes, and to harmonize with the overall form of the temple precinct. It also maximized the usage of the limited site.

- Blending Tradition with Modern Functionality

- The hall was built using a traditional design featuring unfinished wood, creating a dignified yet powerful space both inside and out. A connecting corridor at the same level as the existing Main Hall links the New Hall, Guest Hall, and other spaces, resulting in a layout that is both intuitive and easy to use. The facility also features enhanced accessibility and incorporates warm, inviting materials. In addition, the upper floor uses a steel-frame structure to create a large-span, pillar-free space that ensures flexibility and ease of use.

- Preserving the Heian Style

- As the area surrounding Chuson-ji has been designated a Historic Scenic District, architectural harmony with the surroundings is essential. To maintain the historical landscape, the building was designed based on the Buddhist architectural style of the Heian period, when Chuson-ji was originally founded, and features traditional roof style.

The guest hall (foreground) and New main hall (background) sit atop a cantilevered second-floor slab projecting over the cliff.

Elevation of the Guest Hall

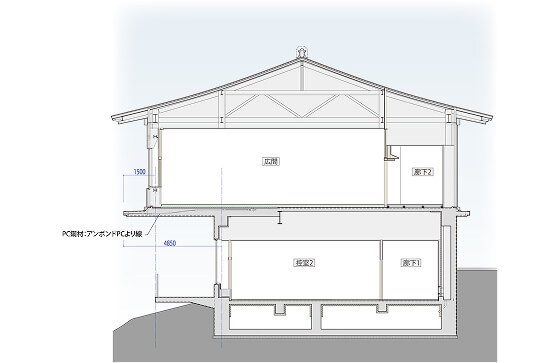

Construction of the cantilevered slab using unbonded PC strand method

- A “Modern Kakezukuri” Built on a Site with Cliffs and Archaeological Remains

- By fitting the new first-floor layout within the footprint of the former guest hall and temple lodging, excavation was kept to a minimum, preserving the archaeological remains while constructing the structure with reinforced concrete. Above this, a cantilevered concrete slab was extended dramatically out over the cliff to create and widen the space of the second floor. Built atop this “modern kakezukuri” foundation are the Buddhist hall and guest hall, combining a steel-frame structure with traditional architectural design.

- Preserving Tradition with Proprietary Technology Seismic Retrofit of the Main Hall

- The Chuson-ji Main Hall, rebuilt in 1909, is a traditional wooden structure that relies primarily on plastered earth walls for seismic resistance. Just before its designation as a UNESCO World Heritage Site in June 2011, the building suffered damage to the walls during the Great East Japan Earthquake. In response to Chuson-ji’s strong request to preserve the original appearance without altering the exterior or functionality, Obayashi carried out a seismic retrofit using its then-state-of-the-art “Super Itakabe” (super panel wall) technology. This high-strength wall system offers over ten times the standard wall strength and can be finished with a traditional plaster coating, preserving both the building’s appearance and usability without compromising aesthetics or functionality.

| Location: | Iwate |

|---|---|

| Client: | Chuson-ji Temple (Religious Corporation) |

| Overview: | Reinforced concrete structure, partially steel-reinforced concrete and reinforced concrete 2 above ground Total floor area: 1,616 m² |

| Design: | Obayashi Corporation |

| Completion: | October 2019 |

(Tentative Name) Yasaka kaikan project (Imperial Hotel, Kyoto)

From Theater to Hotel—Carrying the “Memory of the Town” into the Future through Its Silhouette

Courtesy of Imperial Hotel

Courtesy of Imperial Hotel

Yasaka Kaikan is a theater that has long been beloved as a symbol of Kyoto’s Gion district. After seismic vulnerabilities were identified, the building was closed, but in the spring of 2026, this valuable local landmark will be reborn as the Imperial Hotel, Kyoto. For its revitalization, Obayashi proposed a plan to preserve and expand the structure by retaining two of the exterior walls visible from the street along with the structural frame, thereby carrying forward the building’s iconic silhouette and familiar streetscape. Reconstructing the building in a way that preserves its exterior while also meeting current building code requirements was no easy task. Even so, we took on the challenge—because we believe it is essential to carry forward the memories and history embedded in the building into the future.

Senior General Manager, Architectural Design & Engineering Division / Leader, Traditional Architecture and Heritage Project Team, Obayashi Corporation Masahiro Inoue

Heritage

The Challenge of

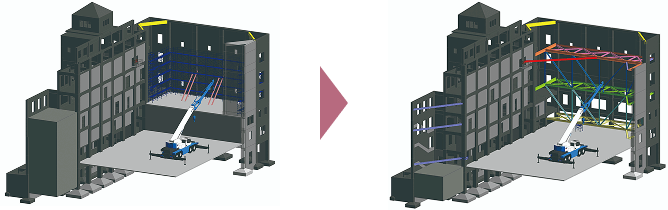

“Selective Demolition” and

“Capturing for Reuse”

Building height restricted to 12 meters in the height restriction area

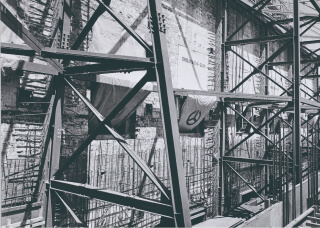

Existing exterior walls reinforced with steel framing in response to demolition phases

The site where Yasaka Kaikan stands is subject to strict building height regulations. Under normal circumstances, rebuilding to the same height would not be permitted. However, through extensive discussions with the Counsil on Aesthetic and Landscape Design, and the Landscape Design and the Landscape Review Board, special permission was granted—on the condition that the building’s silhouette would be preserved and the design harmonize with Gion’s traditional streetscape. As a result, the south and west exterior walls will be retained along with the structural frame.

During demolition, the remaining structure—comprising only exterior walls—was highly unstable and vulnerable to collapse under seismic forces or other stress during construction. To address this risk, structural engineers were brought into the project team from the planning stage, making this an exceptionally collaborative and complex undertaking.

Additionally, the exterior tiles were carefully removed and “captured for reuse,” while well-preserved tiles and terracotta reliefs were secured with pins to prevent them from falling. The project moved forward through ongoing technical trial and error. As demolition progressed, discrepancies were found between the actual structure and the original drawings—dimensions, reinforcement layouts, and other details often did not match. Each time, the site had to be re-surveyed, the design revised, and new permit applications submitted. Compared with a typical demolition and new construction project of the same scale, this one required significantly more time and effort. Nevertheless, we believe that this very experience will serve as a foundation for future efforts to preserve and revitalize traditional architecture and heritage.

100,000 exterior tiles were carefully removed and sorted with approx. 10% reused

Well-preserved terracotta reliefs were pinned in place to prevent detachment

“Challenge” Various Means of Preservation

What should we preserve, and what should we change? The approach to building preservation and renovation has evolved over time. With a wealth of knowledge and technical expertise, Obayashi Corporation is committed to passing great architecture on to future generations.

Architecture

and Living Heritage

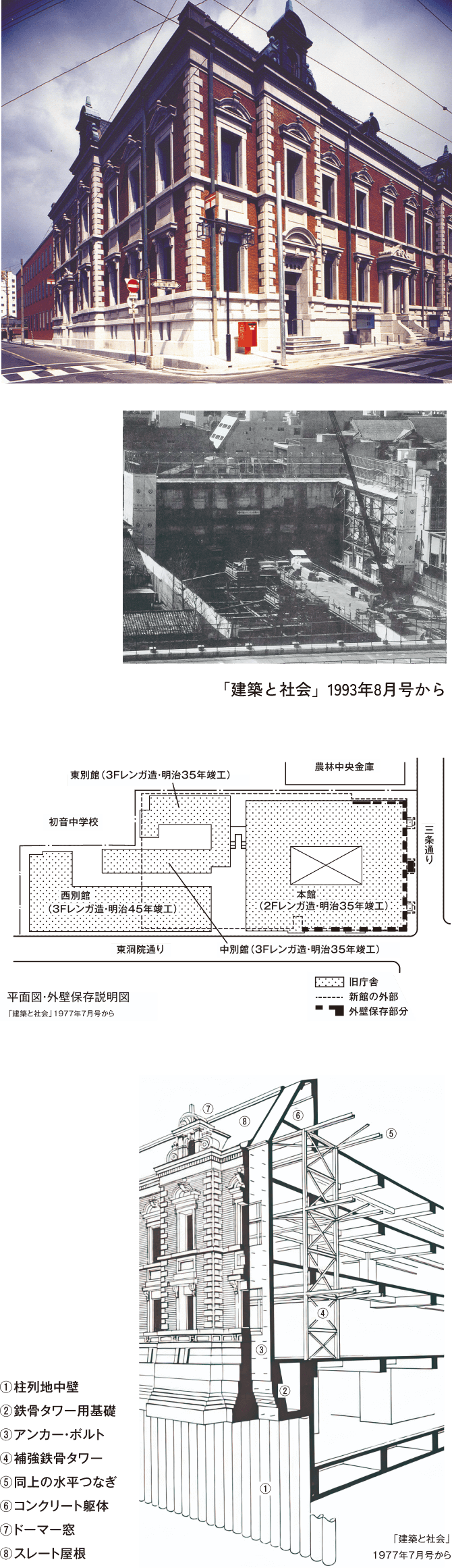

A Pioneer in Facade Preservation Nakagyo Post Office

-

Installation of anchor bolts in the brick exterior wall

-

Preserved facade supported by temporary steel framework

-

Preserved aedicula* and service counter lobby

*An aedicula is a shrine-like architectural feature built into a wall

-

Temporary steel framework and new facade under construction

- Constructing a New Post Office While Preserving the Brick Facade

- This Renaissance-style, two-story brick building, completed in 1902, is a renowned architectural landmark. In March 1976, a project began to preserve its brick exterior walls while integrating them with a new building housing the full functions of a post office. Because the brick walls could not stand on their own, demolition while leaving only the facade intact was not feasible. To prevent the walls from collapsing during construction, a temporary steel framework was built on the inside, using OWS walls and a continuous row of column piles as the foundation. The brick walls were then securely fastened to the steel frame with bolts. This made it possible to demolish the entire old building, construct a new reinforced concrete wall inside using the brick facade as a formwork, and then anchor the two together with epoxy-set bolts. Once this was done, the temporary steel framework was removed. As a result, the project was completed in March 1978, preserving the original exterior while completely rebuilding the interior as a new post office.

| Location: | Nakagyo-ku, Kyoto City |

|---|---|

| Client: | Ministry of Posts and Telecommunications |

| Overview: | Reinforced concrete structure (reinforced portions) 3 above-ground floors, 1 basement level Total floor area: 9,700 m² |

| Renovation design: |

Architectural Division, Minister’s Secretariat, Ministry of Posts and Telecommunications |

| Completion: | March 1978 |

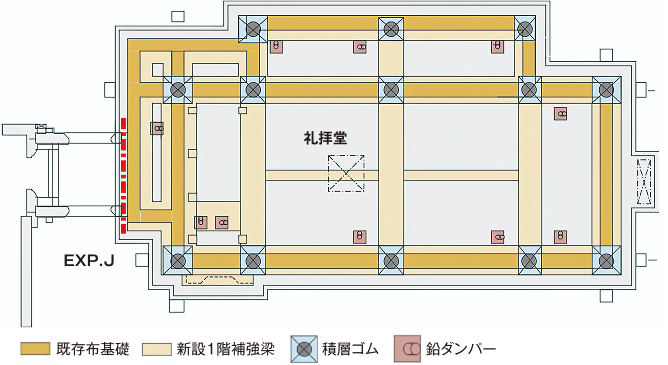

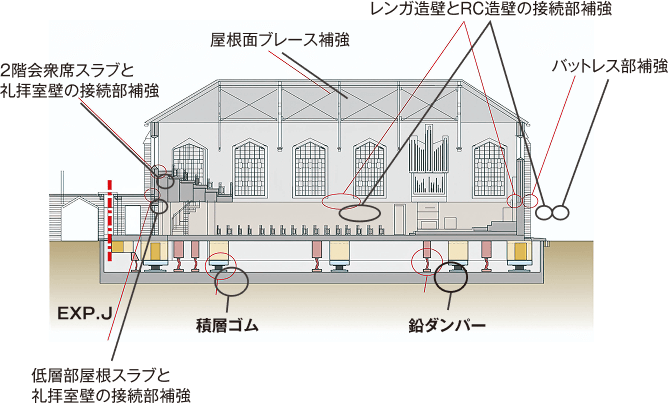

Japan’s First Seismic Retrofit of a Brick Structure Rikkyo All Saints’ Chapel

- A Brick Building Steeped in History

- Since its founding in 1874, Rikkyo University has upheld its educational philosophy of nurturing individuals based on Christian values. In 2000, as part of its 125th anniversary project, the university undertook a redevelopment of its Ikebukuro campus. The campus is home to several red-brick buildings, including the chapel, library, and main building. Among them, Obayashi carried out seismic retrofitting of the chapel—a symbolic structure of the university and a designated Historic Building by the Tokyo Metropolitan Government.

Providing Seismic Isolation Performance Equivalent to New Construction

-

Excavation

-

Steel reinforcement for base plate

-

Completed laminated rubber bearing section

In this seismic retrofit project, the “seismic isolation retrofit method” was applied for the first time in Japan to a brick structure. This method involves installing seismic isolation devices beneath an existing building to reduce the impact of earthquakes—delivering performance on par with newly constructed seismic-isolated buildings. Since the entire building is lifted to install the devices underneath, allowing the building to remain in use during construction. The method allows the work to proceed with minimal changes to both the exterior and interior making it an ideal solution for seismic reinforcement of historic buildings or those difficult to rebuild.

| Location: | Toshima-ku, Tokyo |

|---|---|

| Client: | Rikkyo University |

| Overview: | Reinforced concrete structure (reinforced portions) 1 floor above ground (partially 3 floors) Total floor area: 505 m² |

| Renovation design: |

Nikken Sekkei |

| Completion: | February 1999 |

Preserving a Pre-war Architectural Landmark with Proprietary Technology Osaka Club

Current exterior

Exterior at time of completion

Renovated lounge

Lounge at time of completion

- The Osaka Club: A Social Hub from the Taisho Era

- The Osaka Club was founded on the concept of “gathering,” with its clubhouse serving as the central venue for its activities. Just two years after its establishment, the first clubhouse was completed in September 1914 on the former site of the Bank of Japan’s Osaka Branch. However, the building was destroyed by fire in 1922. A social club cannot exist without its clubhouse, so the members quickly set their sights on rebuilding. The new design was entrusted to Takeo Yasui, founder of Yasui Architects & Engineers, Inc. Blending Southern European architectural elements with touches of Oriental style throughout, the building would later come to be known as one of Yasui’s signature works in his “free style” approach.The new clubhouse was completed in 1924—just 22 months after the fire. (Source: Osaka Club website)

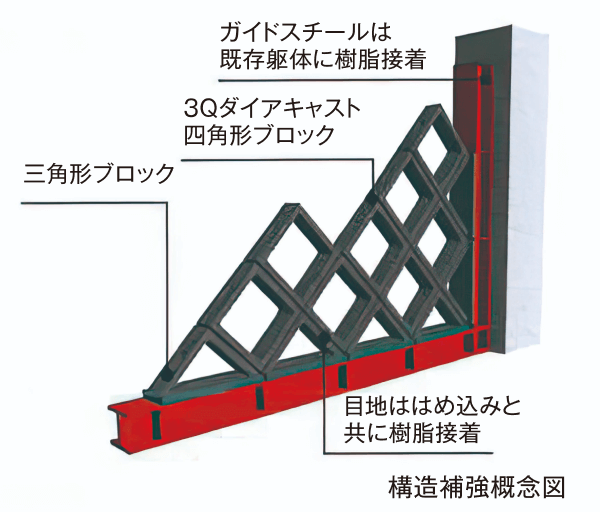

- Seismic Reinforcement Using “3Q Diacast”

- Seismic reinforcement had long been a pressing issue for the Osaka Club. As the original contractor with deep involvement in the building, Obayashi took the opportunity to carry out reinforcement work following the 2017 development of “3Q Diacast”—a cast iron block system characterized by quiet installation, speed, and high quality. Based on a seismic diagnosis, only the second floor—which houses the lounge—was reinforced due to insufficient seismic resistance. The “3Q Diacast” cast iron components provide reinforcement without compromising the atmosphere or openness of the space. The system is also easy to install and minimizes disruption to the surrounding area. Each wall section could be completed in about one week. Although each block is just 90 mm thick, the wall has strength equivalent to a 180 mm reinforced concrete wall. The walls are formed by combining square and triangular blocks.

| Location: | Chuo-ku, Osaka City, Osaka Prefecture |

|---|---|

| Client: | Osaka Club |

| Overview: | Reinforced concrete structure 1 basement floor, 4 floors above ground Total floor area: 3,442 m² |

| Seismic reinforcement design: |

Obayashi Corporation |

| Completion: | October 2017 |

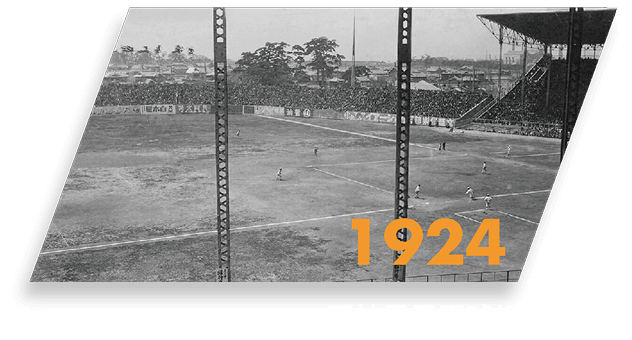

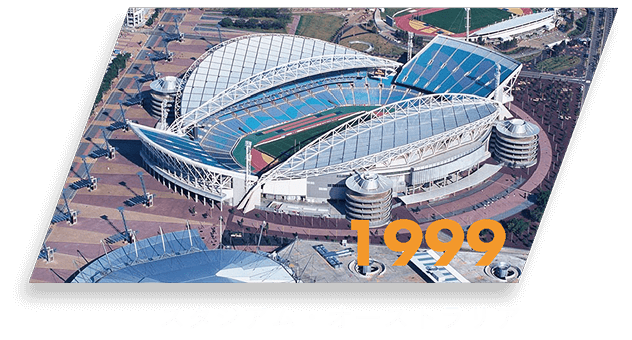

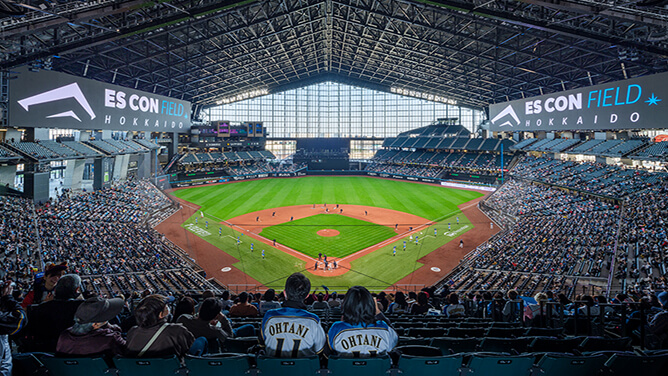

Obayashi Corporation× Stadium and Arena Development

Creating “Cores of the City” That Unite People Through Shared Excitement

Obayashi Corporation has long been committed to creating not just sports facilities, but spaces that generate excitement and serve as vital hubs—“cores”—for their communities. The expertise we have cultivated since constructing Koshien Stadium in 1924 continues to inform today’s state-of-the-art facilities. In recent years, we proposed a new model for ballparks in collaboration with the local community through “ES CON FIELD HOKKAIDO,” and realized a multifunctional arena that revitalizes the urban waterfront in the form of “GLION ARENA KOBE.” What these projects share in common is a focus not just on the physical structure, but on the experiences they generate and the ways they connect with their surrounding cities. Drawing on our long-standing technological expertise and passion for creating new value, we remain committed to shaping the future of sports.

Manager, Architectural Design Department, Architectural Design & Engineering Division Obayashi Corporation Takeo Iwaoka

The Inherited DNA of “Creating Excitement”

The Ultimate Viewing Experience

That Brings You Closer to the Field

- A 360-Degree Circulation Concourse with Views from Anywhere

- The concourse was designed as an open space that allows spectators to watch the game from anywhere within the stadium. This enables fans to enjoy the match while spending time wherever and however they like, without missing the action. Far from being just a passageway, the concourse serves as a key element that helps amplify the crowd’s excitement and fosters a shared sense of unity throughout the stadium.

- Creating a Community with the Ballpark at Its Core

- Part of ES CON FIELD HOKKAIDO, the HOKKAIDO BALLPARK F VILLAGE is more than just a venue for baseball—it is a space for co-creation. It brings together fans, businesses, and local residents with the shared goal of contributing to society and revitalizing the region. While the stadium hosts around 80 home games each year, the area remains lively even on non-game days. It has become an inclusive and creative community space where people of all nationalities, ages, and genders can gather—realizing a new model of urban development centered around the ballpark.

- Bowl-Shaped Seating That Brings You Closer to the Action

- To deliver an overwhelming sense of immersion, a bowl-shaped seating configuration was adopted—designed so that every seat offers a clear, downward view of the field. This layout strengthens the sense of unity between spectators and players by minimizing the distance between them. With the field so close, fans can even sense the players’ breathing and become fully absorbed in the game. This structure is more than just a viewing arrangement—it is a crucial element in creating a stadium where emotional experiences can be shared.

Revitalizing the Historic Pier

That Once Drove Kobe’s Growth—

Now a New Hub of Activity

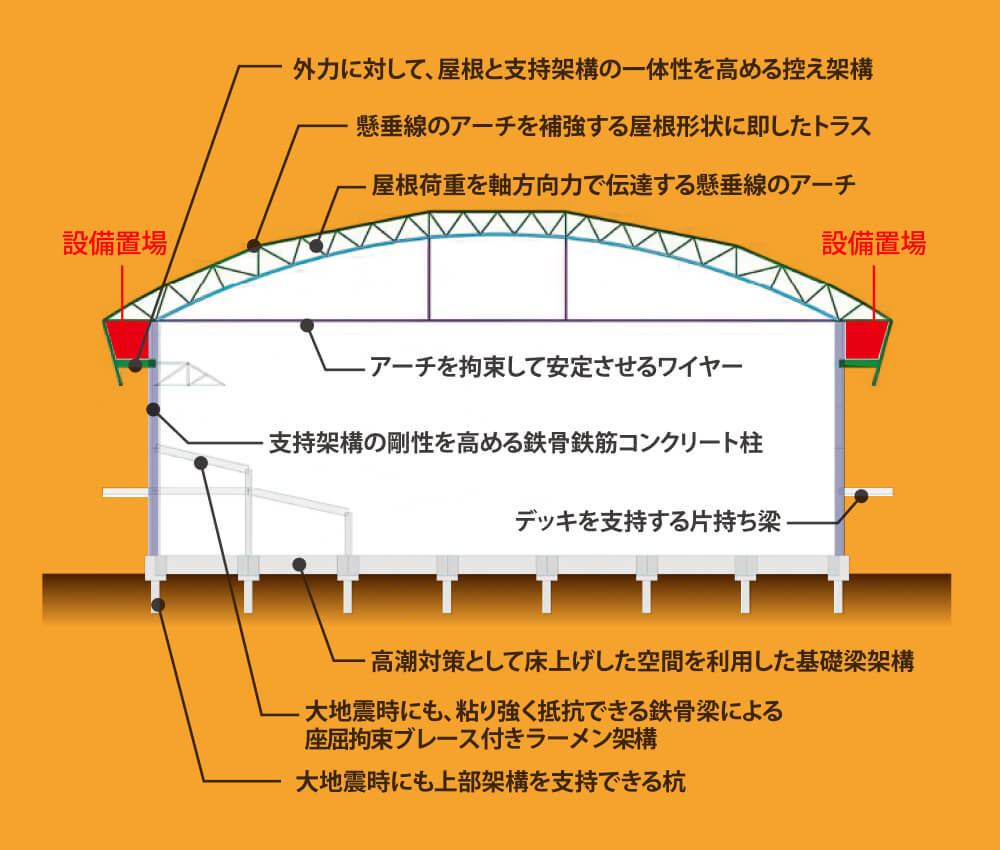

- Breathing New Life into the Pier That Supported Kobe’s Development

- GLION ARENA KOBE stands as a new symbol of the port city, writing a fresh chapter in Kobe’s history. Once used as a docking pier, the site has been transformed into a vibrant space for community gathering and exchange. As a new hub of activity on the waterfront, the arena connects the city’s rich legacy with hopes for the future—continuing to support Kobe’s ongoing growth and revitalization.

- Immersive Bowl-Shaped Design

- As one of the few next-generation arenas in the Kansai region with a capacity of over 10,000, the venue features a horseshoe-shaped seating layout that accommodates not only sports, but also concerts, lectures, and a wide range of events. The design ensures excellent visibility of the stage or court from every seat, delivering a deeply immersive experience for all attendees.

Opening Night Party KENTO MORI Presents “DREAM DANCE LIVE” in GLION ARENA KOBE Courtesy of The Kobe Shimbun

ZEB Ready: A building designed as a precursor to a ZEB (Net Zero Energy Building, where annual primary energy consumption is zero or negative), featuring a highly insulated envelope and high-efficiency energy-saving systems.

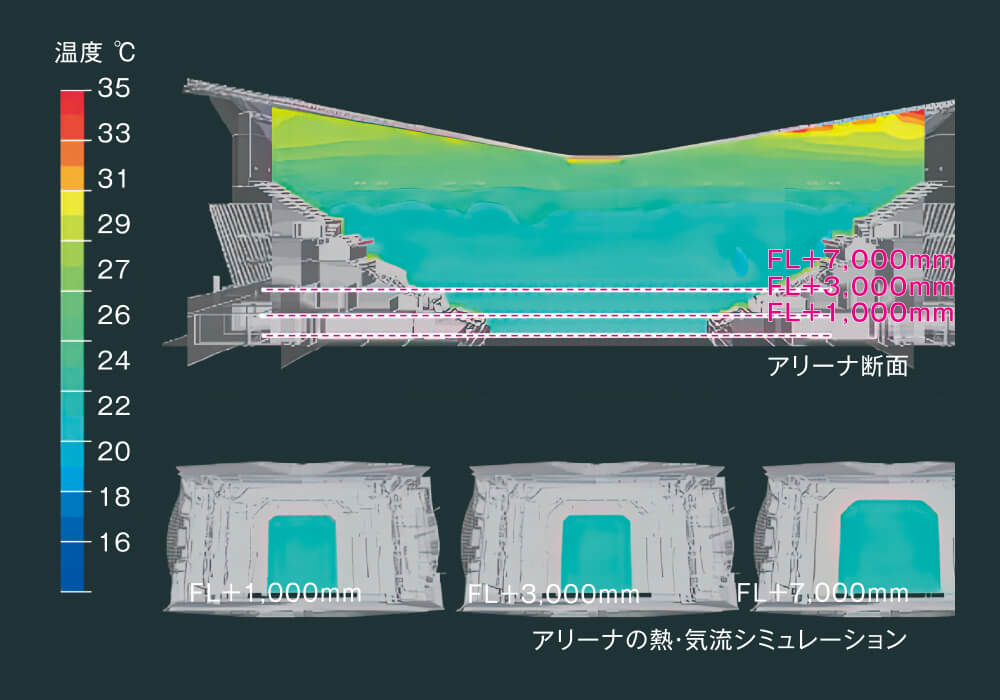

- First Large-Scale Arena in Japan to Achieve “ZEB Ready” Certification

- GLION ARENA KOBE has received “ZEB Ready” certification, highlighting its exceptional energy efficiency. Its distinctive V-shaped roof design, symbolizing Kobe’s ambition to spread excitement and inspiration to the world, optimizes the arena’s interior volume to match the seating configuration. This helps reduce the building’s overall air-conditioning load, contributing to energy savings.

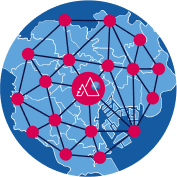

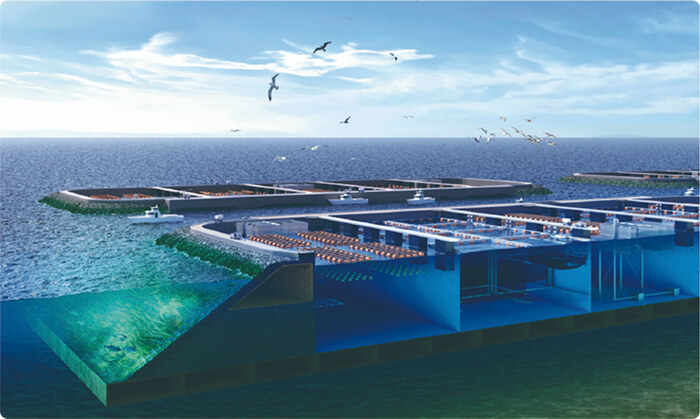

Obayashi Corporation× New Business Initiatives

Beyond Construction—Accelerating “MAKE BEYOND” with new business development

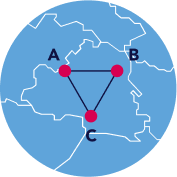

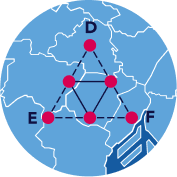

MAKE BEYOND: Obayashi’s new business initiatives are one of the forms of this brand vision—taking on challenges beyond the traditional scope of construction. Our goals are to deliver new value propositions to customers and to create businesses that solve social issues. In other words, we aim to bring new value to society through implementable business models. Following this vision, new companies, i ncluding PLiBOT in 2022 , Oprizon in 2023, and MiTASUN in 2024, were launched. Today, over 30 projects are underway, and we continue to deliver diverse values through synergies with our core business “construction.” Obayashi’s ongoing challenges beyond construction—Stay tuned.

General Manager Business Innovation Integration Division Dr.Tamaki Horii

Businesses

Initiatives

- Turning “Sleeping Buildings” into Urban Infrastructure

Obayashi’s Data Center (DC) Business - Leveraging the strengths we’ve developed across construction and a wide range of business domains, Obayashi is transforming underutilized buildings in urban areas into small-scale data centers—either through renovation or reconstruction. By linking multiple sites via dedicated lines, we are building an urban cluster of data centers that offers functionality on par with large-scale facilities.

-

Urban DC Cluster

Construction -

-

- STEP 1

- Site provision

-

- STEP 2

- Each additional site strengthens

the DC network

-

- STEP 3

- Alliances with other operators

enable interconnectivity

-

- What We Will Resolve

-

-

- Communication Costs

- Urban locations in central Tokyo

offer cost advantages

-

- Low Latency

- High-speed, stable connections suited

for large data volumes

-

- Access Convenience

- High accessibility enables rapid response

in the event of system failures

-

Obayashi Corporation× Expo

History Envisioning a Better Future Beyond the Expo

A World Expo is a gathering place for global wisdom to address the challenges facing humanity. For over 120 years, Obayashi Corporation has played a role in a wide range of expos—continually envisioning a better future and boldly taking on the challenge of making it a reality.

-

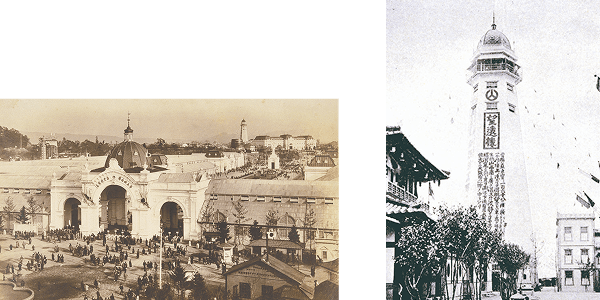

1903

The 5th National Industrial Exhibition Obayashi was responsible for most of the venue construction. The 45-meter-high “Obayashi Tower” drew attention at the time as a rare example of a building equipped with an elevator.

-

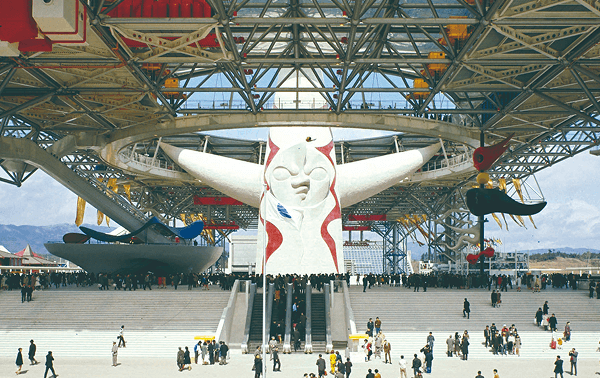

1970

Expo ’70 (Osaka Expo) Obayashi carried out site development, surrounding road infrastructure, and construction of 17 pavilions. Using the latest construction technologies, we brought to life the visions of nations and companies for what 21st-century living could look like.

-

1975

Okinawa International Ocean Expo

-

1985

International Exposition on Science and Technology (Expo ’85 Tsukuba)

-

1990

International Garden and Greenery Exposition (Osaka Garden Expo)

-

2005

Expo 2005 Aichi, Japan

-

2010

Expo 2010 Shanghai

-

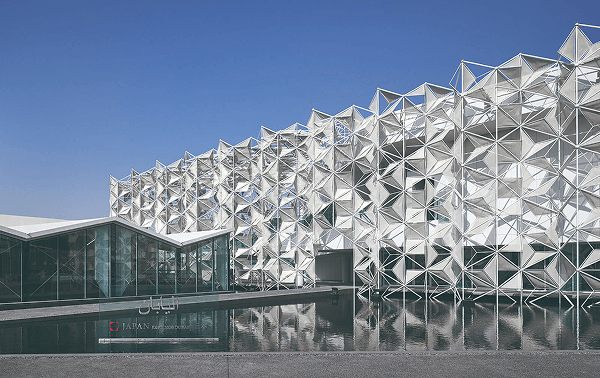

2021

Expo 2020 Dubai The Japan Pavilion, distinguished by its striking white facade designed by Obayashi Corporation, is being reused for the Women’s Pavilion at Expo 2025 Osaka, Kansai, Japan.

EXPO 1970

- Expo ’70 (Osaka Expo)

- Held under the theme “Progress and Harmony for Mankind,” Expo ’70 was the first World Expo to take place in Asia. It showcased Japan’s postwar recovery and technological prowess to the world, while also drawing attention to the social issues emerging from rapid economic growth. To manage the large-scale construction efficiently and accurately, Obayashi established a specialized management system and completed 17 pavilions within a limited timeframe. The massive 8,000-ton roof structure surrounding the Tower of the Sun was erected using the cutting-edge “lift-up method” of the time—a technique that would later become a cornerstone in large-scale and high-rise construction projects.

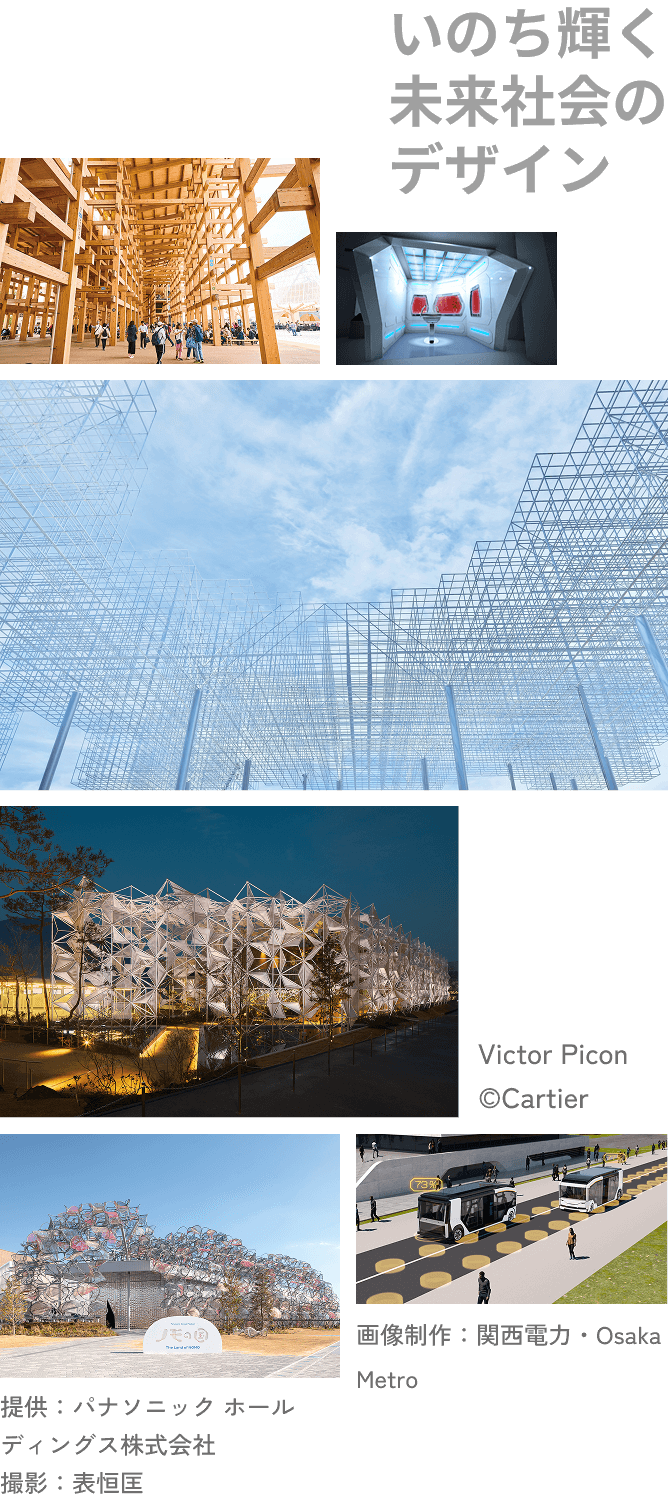

EXPO 2025

- Expo 2025 Osaka, Kansai, Japan

- In today’s world, where values and ways of living are becoming increasingly diverse, Expo 2025 Osaka, Kansai, Japan is being held under the theme “Designing Future Society for Our Lives.” The Expo aims to foster a sustainable society in which each individual can reflect on their desired way of living and fully realize their potential through global co-creation. The focus is shifting—from “how to advance” to “how to live happily,” and further to “how to build a sustainable society to support that happiness.” With awareness of these issues, Obayashi Corporation worked with various partners to construct the related facilities.

The Grand Ring

A symbol of Expo 2025 Osaka, Kansai, Japan and one of the largest wooden structures in the world. Designed by architect and site design producer Sousuke Fujimoto, it embodies the expo’s core philosophy: “Unity in Diversity.”

※Available only in Japanese

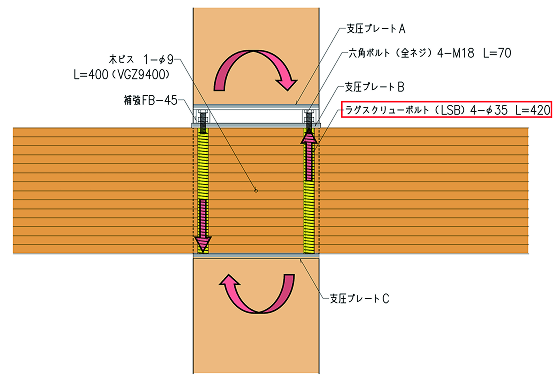

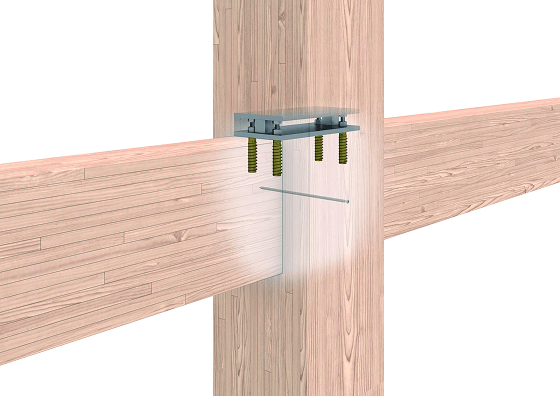

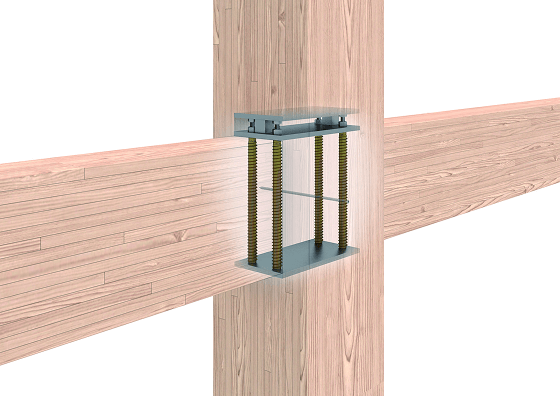

“Nuki” joinery: horizontal beams inserted through holes in the columns and secured in place

- A Structure Designed for Easy Assembly and Reuse

- The construction of the Grand Ring combines the traditional nuki (through-beam) joinery method, as seen in the stage protruding from the main hall of Kiyomizu Temple in Kyoto, with added modern construction methods to increase rigidity. Traditionally, this method uses wooden wedges inserted into the joint to secure the beams, but during earthquakes or strong winds, the wedges can loosen or the beams may compress and deform—potentially leading to structural failure. To meet modern seismic standards, steel plates were placed above and below the column joints, and adjustable lag screw bolts were used to apply tension, firmly compressing the joints. In areas requiring greater strength, a “high-strength type” was used, with the sides of the horizontal beams reinforced with steel plates. In areas with lower structural demands, a “low-rigidity type” was selected—ensuring the optimal specifications for each location. In addition, the Grand Ring will be dismantled and reused after closure of the Expo. Therefore, we conducted experiments on assembling and dismantling a full-scale mock-up to verify methods for dismantling the structure while preserving its condition.

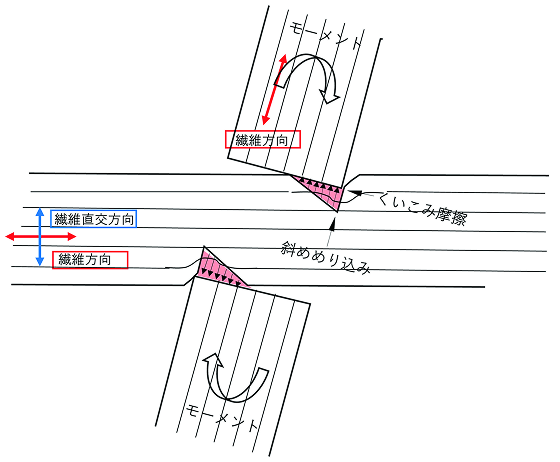

In typical nuki joinery, a beam is inserted through a hole in the column and secured by driving in wooden wedges to apply pressure. However, this method tends to be weaker against indentation on the beam side.

In this improved nuki joinery, the wedge shape was modified to enhance workability and performance. By using nuts and bolts, the system improves strength and stiffness against indentation on the beam side.

Low-Rigidity Type – Interior

Standard Type – Interior

High-Strength Type – Interior

Three types were developed to accommodate the various unit configurations of the Grand Ring

- Contributing to the Revitalization of Japan’s Forestry Industry, with a Focus on Workability and Safety

- In Obayashi’s construction zone, approximately 50% of the column material used is hinoki cypress sourced from Shikoku, while the beams are made from cedar grown in Fukushima. These materials were processed at one of Japan’s most advanced laminated timber production facilities, located in Namie, Fukushima Prefecture. For sections of the roof that serve as walkways for visitors, a wooden framework was combined with 9 cm-thick cross-laminated timber (CLT) panels. These were manufactured using the large-scale CLT production equipment operated by Cypress Sunadaya, part of the Obayashi Group. The outer perimeter of the ring, which reaches approximately 20 meters in height, was assembled on the ground in units, then lifted by crane and connected piece by piece—joining upper and lower segments. To reduce high-elevation work, the walkway fences were pre-attached to the CLT before lifting, and screws were pre-positioned so that final fastening could be completed easily with power tools, improving both safety and efficiency.

Timber Usage for the Grand Ring (Obayashi Construction Zone)

Laminated Timber (Hinoki cypress, European red pine, Cedar)

Approx. 6,500 m³ – Used for columns, beams, and girders

CLT (Hinoki cypress, Cedar)

Approx. 1,800 m³ – Used for flooring

CLT

Cypress Sunadaya produces Japan’s largest CLT panels, measuring 3m × 12m

Women’s Pavilion in collaboration with Cartier

This pavilion is a joint initiative by the Cabinet Office of Japan, the Ministry of Economy, Trade and Industry, Cartier, and the Japan Association for the 2025 World Exposition. It envisions a world where all people—regardless of gender—can coexist in true equality, respect one another, and fully realize their potential. Through the experiences and perspectives of women, the pavilion encourages visitors to pursue a fair and sustainable future. Environmentally conscious construction is also a key feature of the pavilion.

※Available only in Japanese

Victor Picon ©Cartier

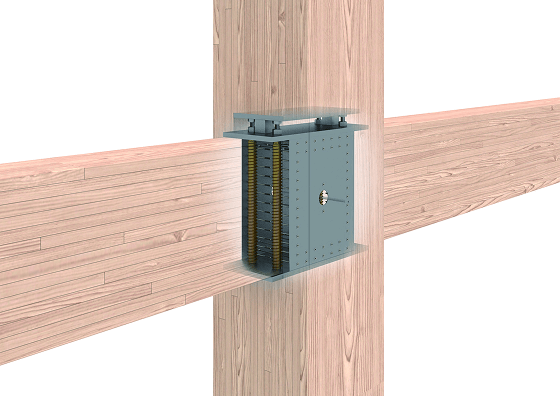

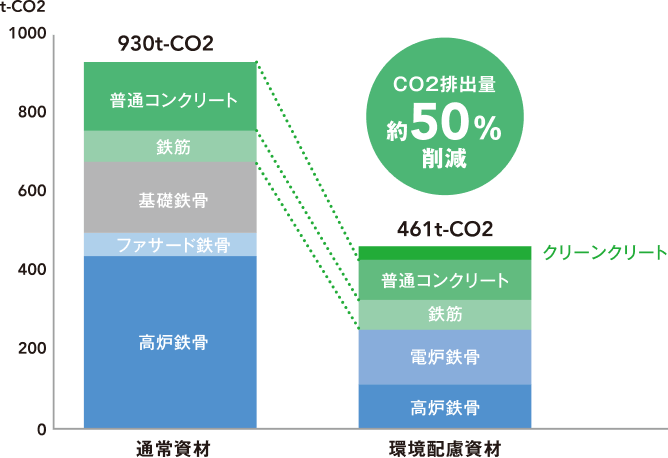

- From Dubai to Osaka—Reusing the Facade

- Obayashi Corporation purchased the facade used in the Japan Pavilion at Expo 2020 Dubai and repurposed it for the Women’s Pavilion. As a result, the construction of the facade produced zero CO2 emissions. In addition, by effectively using low-carbon materials for the steel frame and concrete, as well as leasing steel components for the foundation, the total CO2 emissions from constructing the pavilion were reduced by approximately 50% compared to using conventional building materials.

The facade from the Japan Pavilion at Expo 2020 Dubai was reused for the Women’s Pavilion with a modified layout

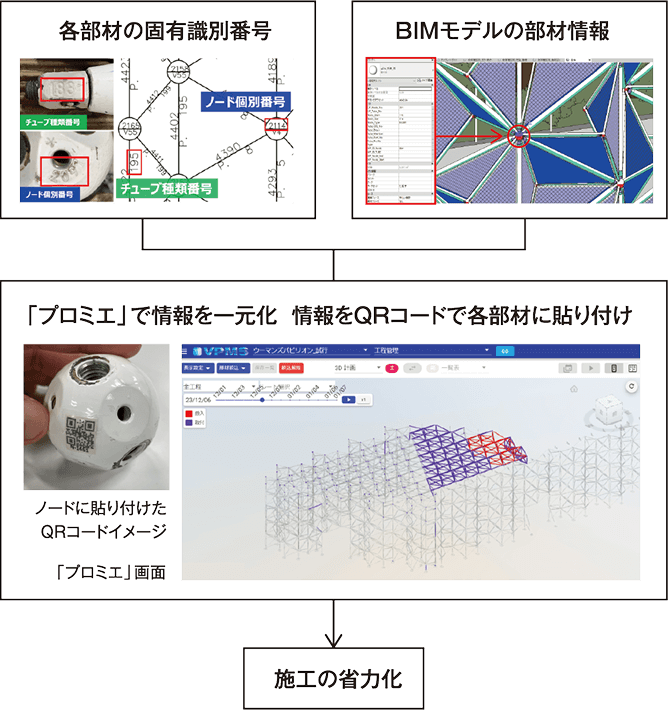

- Facade Assembly Using BIM Data

- In order to rearrange more than 6,000 facade materials, it was important to manage which components were used in which positions. Therefore, we utilized ProMIE, a project management system developed by Obayashi Corporation. The construction area and location of each component are entered into the system. Each component is numbered with a QR code, and by linking the QR code to the information in the system and visualizing it, we have improved work efficiency.

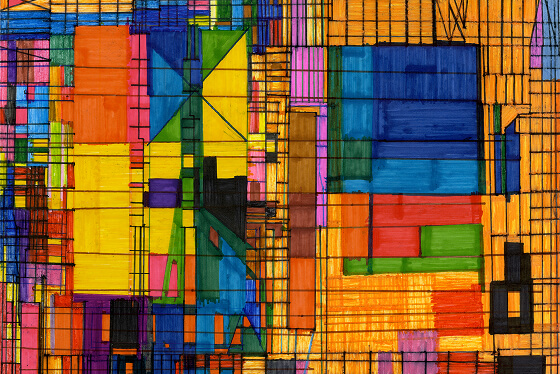

- Collaborating with Heralbony to Create Sitewear

- To express support for the themes of the Women’s Pavilion and Expo 2025 Osaka, Kansai, Japan—fostering empathy and respecting diverse cultures and perspectives—Obayashi collaborated with Heralbony, a creative company that brings the works of artists with intellectual disabilities into society. Together, they produced custom sitewear for construction office staff featuring artwork by these artists.

Artwork by Mr. Kiyoshi Yaegashi, featured on the sitewear.

Kiyoshi Yaegashi, artist of the featured work

| Client: | Richemont Japan LLC |

|---|---|

| Design and Supervision: | Yuko Nagayama & Associates Ove Arup & Partners Japan Ltd |

| Construction: | Obayashi Corporation |

Panasonic Group Pavilion The Land of NOMO

An experiential pavilion that stimulates children's senses and unlocks their imagination. Through exhibition experiences that incorporate Panasonic Group technologies—such as behavioral and facial expression analysis, and immersive spatial design—the pavilion encourages children to believe in their own potential and take their first steps forward.

※Available only in Japanese

Courtesy of: Panasonic Holdings Corporation

Photography: Nobutada Omote

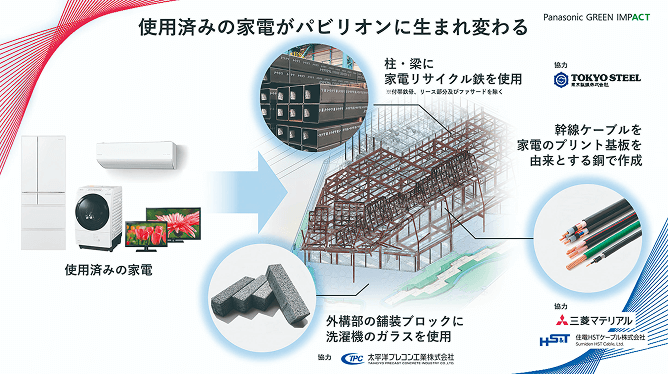

- Recycling Used Home Appliances

- The pavilion incorporates building materials made from recycled iron, glass, copper, and other materials recovered from used home appliances, as well as scrap and waste materials from Panasonic Group factories.

Courtesy of: Panasonic Holdings Corporation

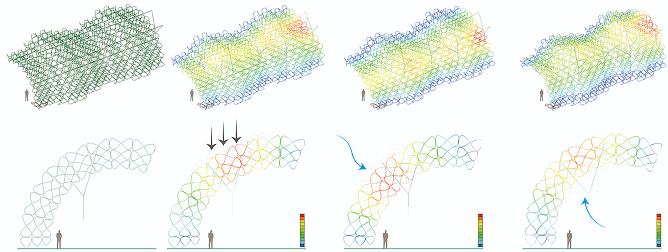

Analyzing the forces and deformations acting on each part of the facade due to self-weight, wind, and other factors

- A Facade That Embodies Circularity

- Designed by architect Yuko Nagayama, this organic and dreamlike facade is composed of approximately 1,400 units. Thin organdy fabric is stretched over a frame of steel pipes shaped using a 3D bending machine, creating a light and fluid architectural form that sways gently in the wind. Obayashi took on the challenge of bringing this unique facade to life through full-scale mockup testing and detailed structural analysis.

- Automated Control of Facade Effects

- The facade’s visual effects are automatically controlled through the integration of Electric Works Company, Panasonic Corporation’s “YOI-en” urban development cloud system and Obayashi Corporation’s smart building platform “WELCS place.” WELCS place collects real-time data such as temperature, humidity, rainfall, and wind speed, and sends signals to YOI-en based on preset thresholds. This enables mist spray control that adapts to the environment. The system helps maintain optimal conditions for the light, sound, and mist display that enhances the pavilion’s exterior—and also serves as a measure against daytime heat.

| Client: | Panasonic Holdings Corporation |

|---|---|

| Design and Supervision: | Obayashi Corporation Yuko Nagayama & Associates Kozo Keikaku Engineering Inc. Ove Arup & Partners Japan Ltd |

| Construction: | Obayashi Corporation |

Wireless Power Supply While in Motion

- Large-Scale EV Bus Demonstration at the Expo Venue Underway

- Obayashi Corporation, together with Kansai Electric Power, Osaka Metro, and DAIHEN Corporation, has formed a consortium to support the EV Bus Transportation Project—part of the Future Society Showcase at Expo 2025 Osaka, Kansai, Japan. To enable wireless charging of EV buses while in motion, the material covering the top of the power transmission coils must be non-magnetic and durable enough to withstand the weight of passing vehicles. Additionally, to ensure high power transfer efficiency, the coils must be embedded just beneath the road surface. Obayashi took on the challenge of addressing these requirements while carrying out the coil installation work.

To solve these challenges, the embedded coils were installed as part of a precast coil unit integrated with the pavement. The underside of the unit was constructed with reinforced concrete, and metal enclosures were used to securely house auxiliary equipment. Between the coils and the road surface, Obayashi applied a newly developed low-carbon variant of its high-performance cement composite material—Universal-Crete GX—specifically designed for in-motion wireless charging applications. This also contributes to reducing CO2 emissions. Universal-Crete is reinforced with organic fibers to enhance durability. Since these fibers are non-magnetic, they do not interfere with the power transmission efficiency. As a result, the pavement structure—just 25 mm thick—is strong enough to support vehicle loads while also maintaining efficient wireless power transfer.

※Available only in Japanese

Image production: Kansai Electric Power / Osaka Metro

Installation of precast coil unit

Upon completion of precast installation

The installation of power transmission coils at Expo 2025 Osaka, Kansai, Japan is being carried out with support from NEDO (New Energy and Industrial Technology Development Organization).

Signature Pavilion Better Co-Being

Designed by SANAA, the architectural duo of Kazuyo Sejima and Ryue Nishizawa, this pavilion blends seamlessly into the surrounding “Forest of Tranquility.” It defies conventional architectural notions by eliminating both ceilings and walls. An 11-meter-high silver canopy, composed of four layers in a grid-like structure, stretches across the site. Only slender columns, carefully positioned and precisely connected, support it from the ground—giving the impression that the canopy is floating like a cloud. The structure provides no shelter from wind or rain, embodying the core philosophy of the Better Co-Being Pavilion. It also serves as a stage for immersive, art-centered experiences.

※Available only in Japanese

Obayashi Corporation constructed not only the pavilion, but also developed Better Co-Being, an application that can be used throughout the Expo site, with a focus on the pavilion. We are also taking on the challenge of creating new towns by applying this initiative to actual towns as a legacy of the Expo.

| Client: | Japan Association for the 2025 World Exposition |

|---|---|

| Executive Producer: | Hiroaki Miyata (Professor, Department of Health Policy and Management, Keio University School of Medicine) |

| Architectural Design: | SANAA (Kazuyo Sejima & Ryue Nishizawa) |

| Construction: | Obayashi Corporation |

PASONA NATUREVERSE “OPELUMI”

- What Is OPELUMI?

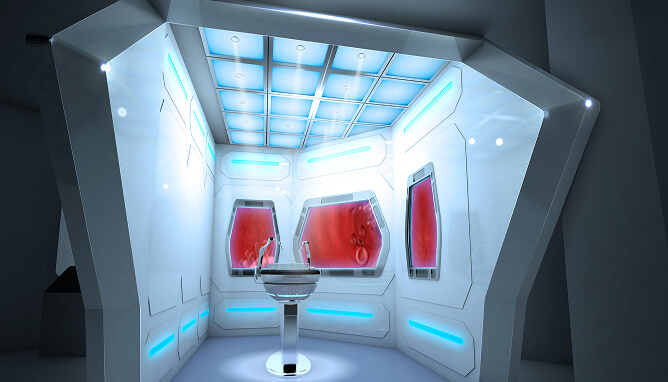

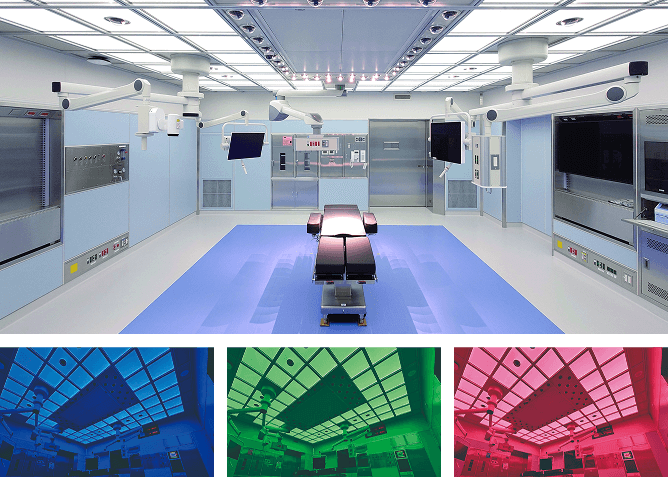

- OPELUMI is an advanced operating room system that eliminates the need for conventional large, disc-shaped shadowless shadowlesslights by integrating equivalent lighting functionality directly into the ceiling. This reduces heat-related stress on surgeons and improves airflow within the operating room—helping to lower the risk of infection. The system combines high-output, high color-rendering automated shooting lights that illuminate the surgical field, with full-color LED panel lighting using light guide plates to evenly light the entire space. These components can be freely configured based on the size and needs of each facility. Because there are no ceiling-mounted surgical lights to interfere with other suspended medical equipment, OPELUMI is ideally suited for robot-assisted operating rooms and hybrid emergency rooms equipped with angiographic CT systems. Looking ahead, Obayashi is also exploring applications of this technology in mobile operating rooms for use in disaster zones and remote areas.

※Available only in Japanese

- PASONA NATUREVERSE

- This pavilion, produced by Dr. Yoshiki Sawa—Professor Emeritus at Osaka University and a leading figure in regenerative medicine using iPS cells—was created by Pasona Group Inc. One of its featured exhibits, the “Future of Medical Care: Remote-Controlled Flying Operating Room,” includes a display of “OPELUMI,” a ceiling-mounted surgical lighting system that eliminates the need for traditional shadowless shadowlesslights. Obayashi Corporation co-developed this system with Dr. Sawa and is supporting the exhibition.

Color adjustment functionality provided by OPELUMI

- First OPELUMI System Installed at Osaka Police Hospital

- In January 2025, the first OPELUMI system was installed in an operating room at Osaka International Medical & Science Center (located in Tennoji Ward, Osaka City; Director: Dr. Yoshiki Sawa). The system is now being used in actual surgeries, primarily in cardiovascular procedures. Doctors using OPELUMI have praised its exceptional brightness, recognizing it as a significant enhancement to the surgical environment.

Taking On the Challenge of Advanced Technology

- This Is a Testing Ground for the Society of the Future

- In constructing the Expo 2025 venue, we set out to explore new ways of building that would lead into the future. Yumeshima, the site of the Osaka-Kansai Expo, is a vast greenfield area located close to a major urban center. It has been designated as a “Super City-type National Strategic Special Zone,” allowing for regulatory flexibility in planning and developing new urban infrastructure such as roads and energy systems. Against this backdrop, leading-edge solutions are being implemented and tested in pursuit of a globally recognized model for a sustainable city. The first step in this grand endeavor was the construction of the Expo venue itself. Treating the site as a “city” and the workers as its “citizens,” we introduced a range of digital technologies to streamline site management and improve working conditions. The completion of the venue is not the end goal—it is just the beginning. The insights and experience gained here will contribute to solving urban challenges and improving quality of life for citizens in the smart cities of tomorrow.

Senior General Manager, Yumeshima Development Promotion Division Osaka Main Office, Obayashi Corporation Manabu Kadoshige

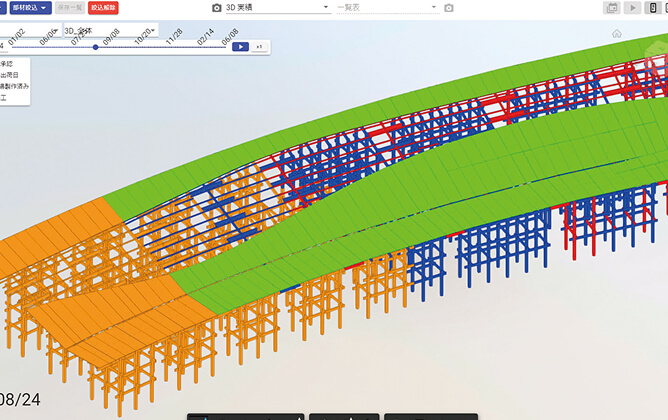

- Introducing a range

of technologies to accelerate

construction DX - We customized cutting-edge technologies for construction and introduced them at large-scale construction sites where large numbers of people and things move around every day. We took on the challenge of construction DX, which greatly changes conventional construction methods.

-

- Construction Vehicle Management System “FUTRAL”

- At the Expo construction site, up to 1,000 vehicles enter and exit each day. Obayashi advanced its proprietary system “FUTRAL” specifically for the Expo project, enabling centralized management of all vehicles on-site and helping to prevent congestion in the surrounding area.

-

- Facial Recognition Entry and Exit System

- At peak times, over 5,000 workers are on-site each day at the Expo construction site. To manage this scale efficiently, world-class facial recognition systems were installed at all entry and exit gates, enabling advanced security and real-time monitoring of worker numbers.

-

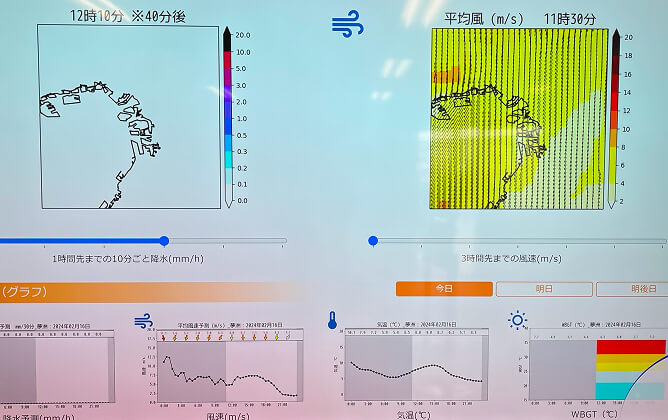

- AI-Based Weather Forecasting for Construction

- In collaboration with Osaka Gas, Obayashi customized AI-driven weather prediction technology for use on construction sites. By training the system on weather patterns specific to the Expo venue area, the accuracy of forecasts was improved. The system also delivers critical weather alerts—such as those affecting construction activity—directly to smartphones and other devices in real time.

-

- Progress Management App “ProMIE”

- The company developed a web application that leverages BIM models to enable real-time progress management for tasks such as structural work. For the construction of the Grand Ring, the entire process—from timber production to on-site delivery and installation—was centrally managed to streamline operations.

-

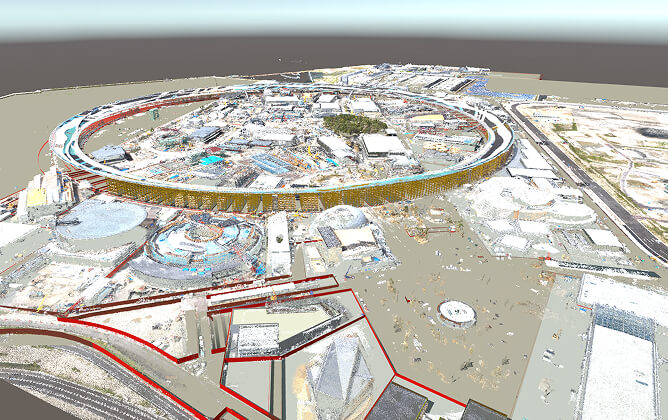

- Point Cloud Capture Using Autonomous Drones

- Autonomous drones were deployed to monitor the vast construction site. In addition to capturing images and video, the drones instantly generate 3D point cloud data that can be shared. This enables remote teams to check the latest site conditions in real time and carry out progress tracking and dimensional measurements from afar.

-

- Digital Twin System

- A digital twin of the construction site was created by overlaying 3D-designed BIM models onto point cloud data captured by autonomous drones. By integrating the positions of workers, construction machinery, and other elements within the 3D space, the system enables safe and efficient construction planning.

From the Expo

to the Future

-

Chapter 01 SOLUTION

Low-Carbon Technologies and Initiatives in the Construction Process

See MoreFrom material production to construction, operation, renovation, and demolition—this chapter introduces the Obayashi Group’s technologies, initiatives, and real-world examples aimed at minimizing CO2 emissions at every stage of the construction process.

-

Chapter 02 VISION

Obayashi’s Vision for a Decarbonized Society

See MoreExplore the Obayashi Group’s wide-ranging visions and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of the construction industry. Themes include resource circulation, biodiversity, energy, and transportation infrastructure.