Please note that some content is only available in Japanese

Chapter 01 SOLUTION Low-Carbon Technologies and Initiatives in the Construction Process

SOCIAL PROBLEM Demolition

- We don’t see demolition as the end—but as the start of creating the future through reuse and recycling.

-

Demolishing buildings and structures generates a large volume of waste.

What’s more, building something new requires fresh construction materials, and their production inevitably emits CO2.

But what if we could reuse structural components like old clothing, or recycle them like plastic bottles? Wouldn’t that contribute to decarbonization?

That’s exactly what we believe—so we’re actively working on initiatives that look beyond demolition to what comes next.

Component and Structural Frame Reuse

How far can we go in reusing building components?

Achieving a circular economy is our mission.

- Exciting forms of “regeneration” have the power to shape a new world.

-

While it’s important to reuse as many components and structural frames as possible, if the reborn architecture becomes even more appealing, efforts toward reuse and recycling are likely to accelerate. We believe that maximizing the value of components and structural frames generated through demolition is key to achieving a true circular economy. By combining “using as is” with “reconfiguration,” we aim to reduce waste and CO2 emissions from demolition—pioneering new frontiers in reuse and recycling that no one has ventured into before.

We are actively adopting systems and sustainable technologies that promote the maximum circular use of building materials.

Component Reuse

First in Japan to reuse structural components in new construction

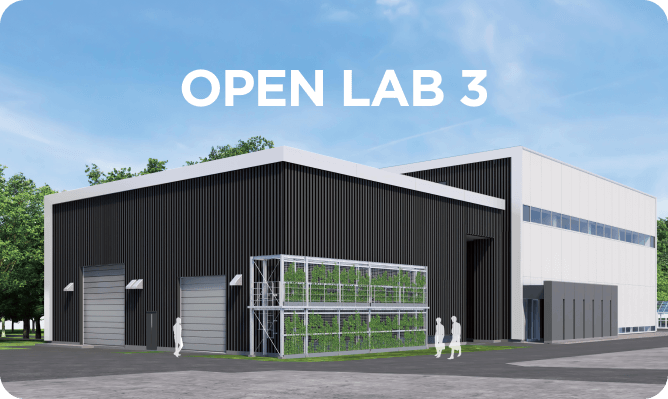

OBAYASHI CORPORATION TECHNOLOGY RESARCH INSTITUTE, OL3

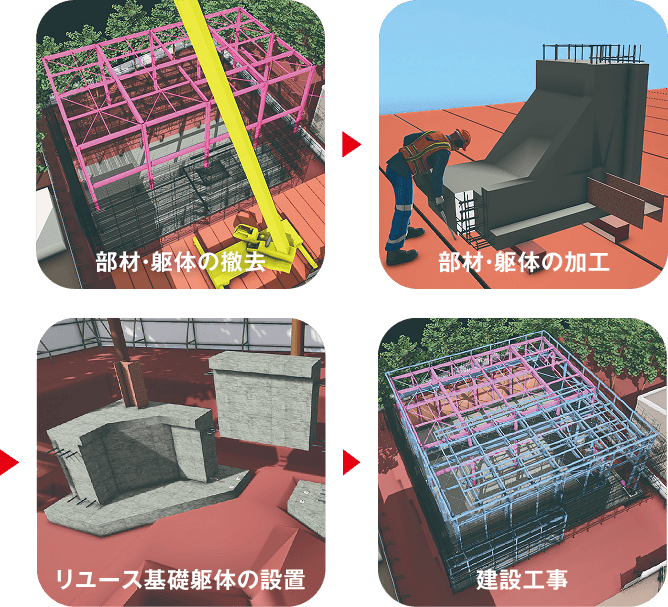

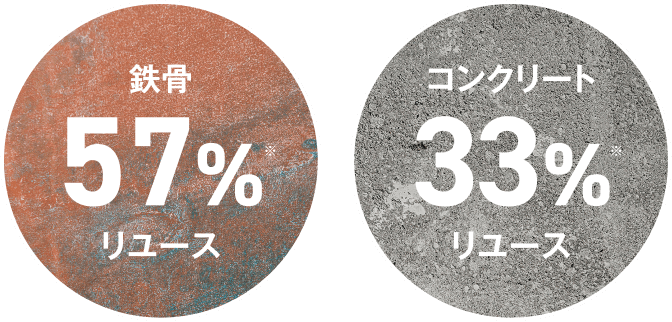

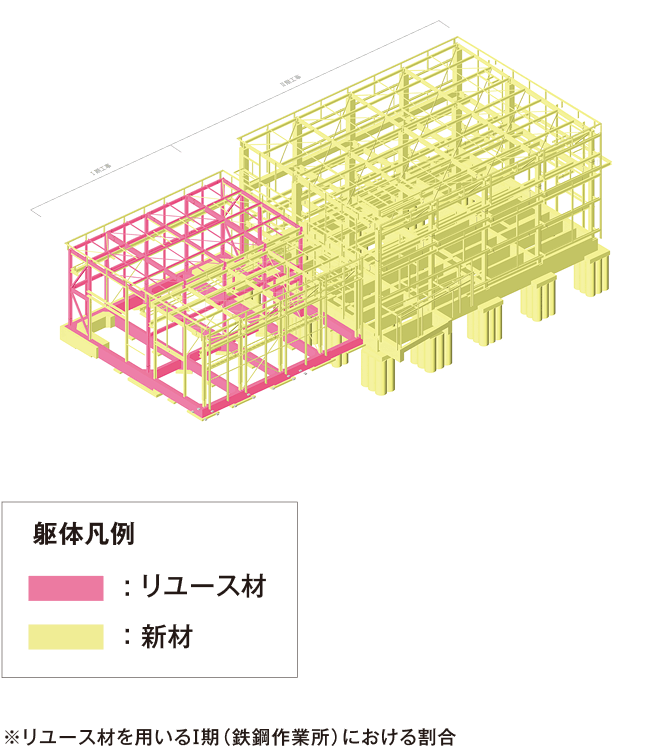

This is a new research facility currently under construction at OBAYASHI CORPORATION TECHNOLOGY RESARCH INSTITUTE. In an unprecedented initiative, steel beams and concrete structural members—normally destined for recycling—are being reused as the structural frame of a newly constructed building. By giving new life to previously used materials in a completely different building, the project breaks new ground in sustainable construction. As a facility embodying sustainability, it promotes resource conservation and CO2 reduction through advanced energy-saving, reuse, and recycling technologies.

Construction underway at the OBAYASHI CORPORATION TECHNOLOGY RESARCH INSTITUTE!

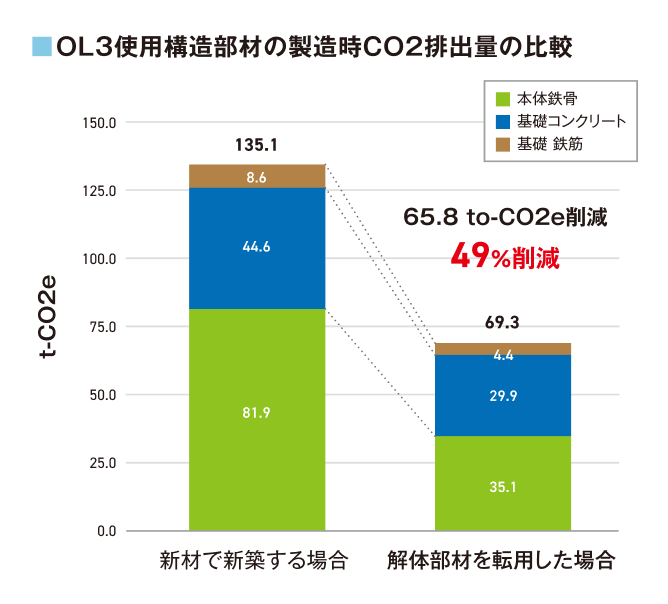

CO2 emissions cut in half compared to using entirely new materials

By reusing structural components from a demolished building, CO2 emissions associated with manufacturing structural members can be reduced by approximately 49% compared to sourcing all new materials. In addition, when compared to using recycled materials, reusing components significantly reduces CO2 emissions during manufacturing.

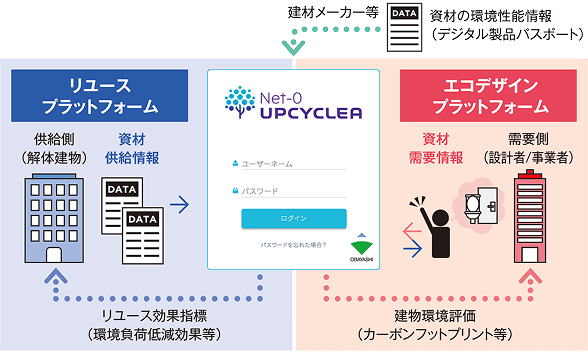

Obayashi is utilizing the reuse platform Upcyclea

Obayashi is utilizing the reuse platform Upcyclea, which visualizes the environmental performance of construction materials and their potential for reuse*. The platform’s built-in AI allows it to match supply information for reusable materials from demolition sites with demand from new construction sites.

*Reuse potential: Indicates that construction materials are in a condition—both in quality and function—that allows them to be reused in other buildings, with measurable reductions in environmental impact.

Maximizing the use of components and structures from existing buildings

Structural Reuse

Contributing to a stock-based society by reusing existing structures

Gotanda JP Building

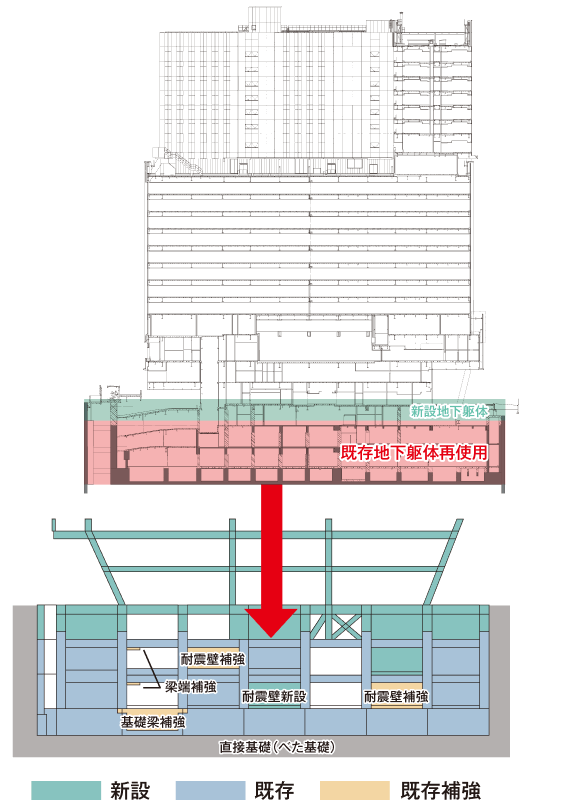

This project sought to maximize the permanent reuse of the existing underground structure of the former Gotanda U-Port Hall building, while also maximizing business value. It aimed to establish a new approach for a stock-based society and realize an upcycled building that serves as a new urban hub. By reusing the existing structure and combining it with low-carbon materials, the project achieved a 15% reduction in upfront carbon (equivalent to 11,408 t-CO2e).

Since the weight of the superstructure increased compared to the original, many seismic walls were added to the underground structure to withstand the additional load. These seismic walls were also used to reinforce beams and columns, and to connect new columns to existing ones that were offset, ensuring proper stress transfer. Beyond reusing the structure, it was also repurposed to serve a new function as a parking facility.

-

Chapter 02 VISION

Obayashi’s Vision for a Decarbonized Society

See MoreExplore the Obayashi Group’s wide-ranging visions and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of the construction industry. Themes include resource circulation, biodiversity, energy, and transportation infrastructure.

-

Chapter 03 CREATION

Realizing a Decarbonized Society and Creating New Social Value

See MoreExplore the many new value creation initiatives the Obayashi Group is making toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.