Please note that some content is only available in Japanese

Chapter 01 SOLUTION Low-Carbon Technologies and Initiatives in the Construction Process

SOCIAL PROBLEM Construction

- By changing how people work and how machines operate, we are reducing CO2 emissions.

-

Every construction site is different in terms of space and environment, which means what we build—and how we build it—varies every time.

Unlike a factory production line where identical products are made in succession, construction sites involve people with diverse skill sets and a wide array of machinery. As a result, inefficiencies—such as overwork, waste, and inconsistency—inevitably occur.

These inefficiencies lead to even greater CO2 emissions through the movement of people and equipment.

So, what if we could automate the construction site, just like a factory? We’re now exploring that very possibility.

Transforming the Construction Production Process

Let’s evolve toward “advanced worksites.”

This will lead to the elimination of overburden, waste, and unevenness.

- Maintaining productivity through cyber-based production processes to build a sustainable society.

-

On-site construction often involves extreme heat, idle time, and rework—issues of overburden, waste, and unevenness. Declining labor availability and a shortage of skilled workers continue to reduce productivity and increase environmental impact. Obayashi’s “Robotics Construction” initiative envisions eliminating these inefficiencies through optimized planning and high-quality execution driven by cyber-connected systems. The goal is a construction production process that is sustainable for both people and the planet.

Advancing the smartification of construction sites by synchronizing cyber and physical spaces through a new approach.

Obayashi's “Robotics Construction”

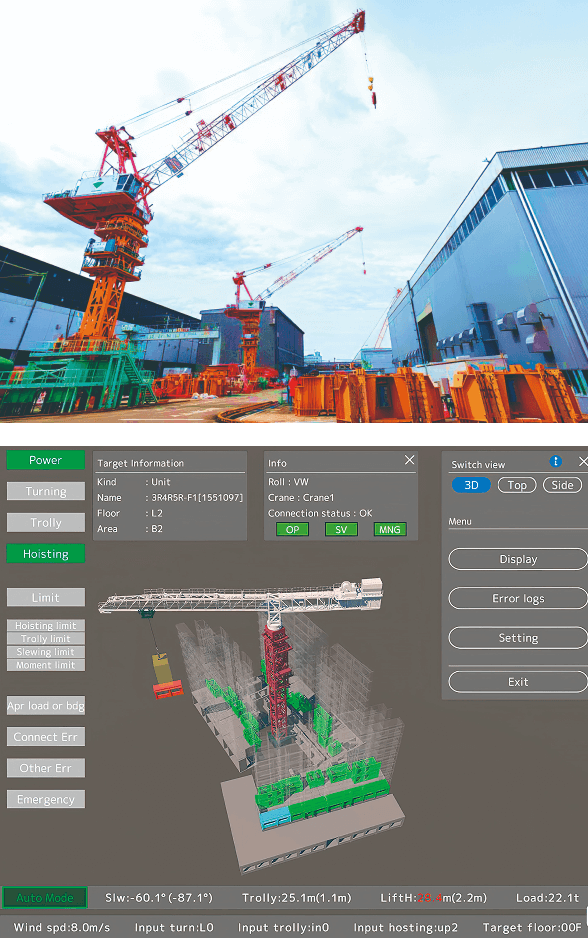

By building a dynamic Cyber-Physical System (CPS) that is synchronized with the construction site, we monitor digital twins of construction machinery and surrounding environments in cyberspace to plan operations, enabling automation and remote operation of construction machinery.

Safer and More Efficient Remote Construction Work

Remote Crane Operation Enables Safe and Efficient Lifting Tasks

The decline in the labor force and shortage of skilled workers lead to decreased productivity.

By utilizing digital twin technology and integrating remote and autonomous operation functions, skill supplementation, and management capabilities, we can enhance safety and curb the drop in operational efficiency.

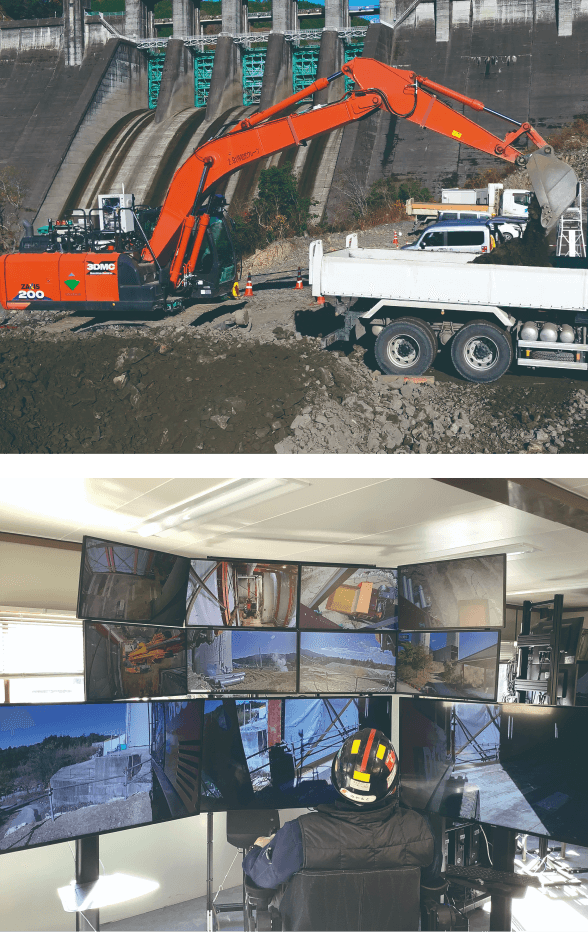

Safe and Efficient Heavy Machinery Operation

Remote-Controlled Dam Embankment and Chimney Demolition

A single supervisor can manage a full series of dam embankment operations—including loading, transport, and leveling. Construction machinery can be safely operated from a distance, away from demolition sites that are difficult for people to access. This approach addresses labor shortages and declining skills, contributing to labor-saving in heavy machinery operations.

The electrification of construction machinery and the use of biodiesel fuel have also begun.

Toward Zero-Carbon Construction with the Introduction of Electric Construction Machinery

Adoption of Battery-Powered Large Electric Construction Machinery

In October 2024, a 20-metric ton class battery-powered excavator was charged using an engine generator powered entirely by biodiesel fuel at a tunnel construction site. Moving forward, we will promote the adoption of electric construction machinery at various sites as part of our efforts to achieve carbon-free operations during use of machinery.

Promoting Resource Circulation Toward Zero-Carbon Construction

Utilization of Biodiesel Fuel

We are promoting the use of 100% biodiesel fuel refined from used cooking oil collected from households—including waste oil generated at our own company cafeterias—through a commissioned manufacturer, for use at construction sites. In addition to building a resource circulation process from fuel procurement to usage, we are also working to reduce CO2 emissions derived from diesel by promoting the use of alternative fuels.

Shield

Tunnels

Minimizing trouble—

That’s the secret

to reducing energy consumption deep underground.

- In the darkness of the underground,

where you can’t see even an inch ahead,

we illuminate with cutting-edge technology. -

You never know what obstacles lie underground. Shield tunneling work through urban areas is truly a process of groping in the dark. While we carry out construction by gathering and analyzing vast amounts of data, even a single oversight or misjudgment can result in having to redo the work. Such troubles can significantly increase CO2 emissions. While human experience and intuition are important, we are striving to capture the invisible underground conditions with advanced technology and guide decisions in the right direction using AI. Developing technologies that make tunnel construction safer, more secure, and more efficient—that is our challenge.

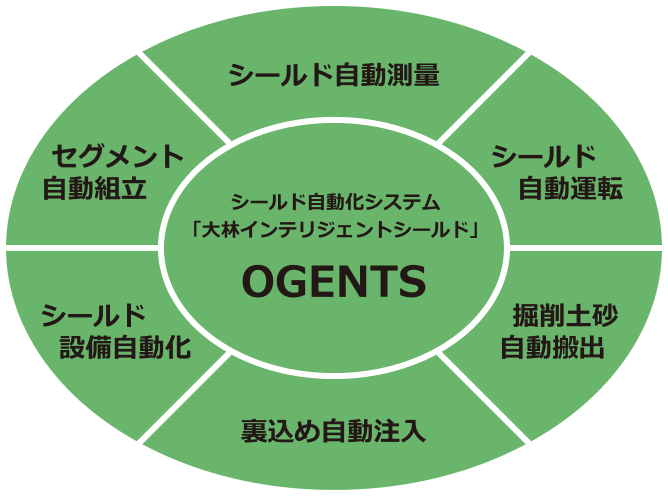

We are developing a system that integrates six technologies

to automate and autonomously operate tunnel construction.

Automating Various Shield Tunneling Operations

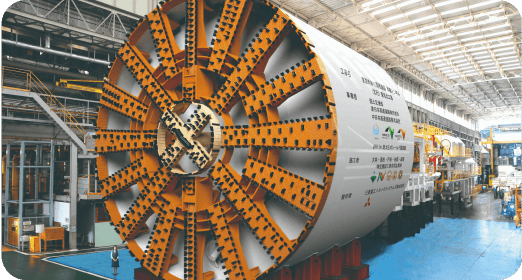

OGENTS

To address the growing issue of labor shortages caused by population decline and an aging workforce, OGENTS is a system that integrates automation technologies for six key processes involved in shield tunneling. By linking these processes, OGENTS enables the overall automation of shield construction, making it possible to both reduce labor requirements and improve construction quality.

-

High-speed Excavation and

Energy Saving with Dual Cutter System Energy-saving Shield -

By dividing the cutterhead at the front of the shield machine into outer and inner sections that rotate independently, each can be set to its optimal speed, enabling efficient excavation. This method allows for faster tunneling and reduced power consumption, especially in the excavation of large cross-section tunnels.

See More

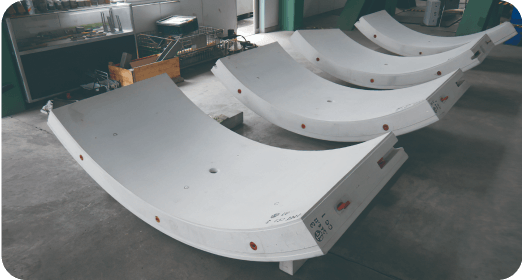

- Environmentally Friendly Segments Clean-Crete Segments

-

By using Clean-Crete—concrete mixed with ground granulated blast-furnace slag—in the reinforced concrete segments that form the lining of shield tunnels, CO2 emissions can be significantly reduced compared to segments made with conventional concrete.

See More

-

Achieving Net-Zero

or Lower CO2 Emissions

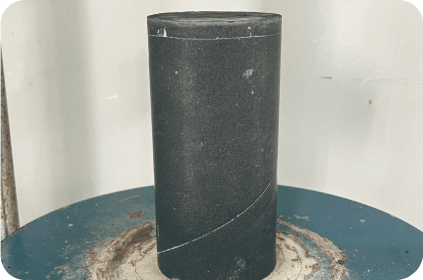

During Construction Carbon-Neutral Backfill

Grouting Material -

In shield tunneling, the gap between the assembled segments and the surrounding ground is typically filled with cement-based grouting materials, which emit CO2 during production. By replacing these with biochar—capable of capturing and storing carbon—it is possible to achieve a net CO2 reduction of approximately 105%.

See More

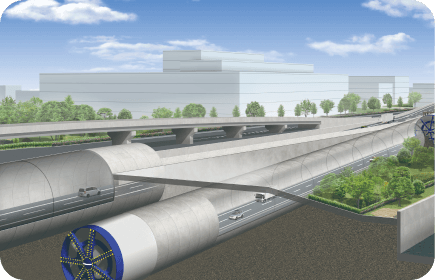

- Reducing CO2 Emissions with Ground-Level Launch and Arrival URUP Method

-

By enabling shield tunneling to start and end at ground level, the URUP (Ultra Rapid Under Pass) method eliminates the need for shaft construction and open-cut excavation. This reduces the use of large construction machinery and decreases the number of dump trucks needed for soil removal, thereby significantly lowering CO2 emissions.

See More

From Hokkaido to Kyushu,

Our shield tunneling technology

is driving progress beneath Japan’s cities.

Reducing CO2 Emissions through Smoother Traffic Flow

Tokyo Outer Ring Road

Sections of the Tokyo Outer Ring Road are being constructed using the shield tunneling method. By improving traffic flow, the project is expected to significantly reduce CO2 emissions generated by vehicles.

First Application of Clean-Crete Segments

Okayama Electric Power Utility Tunnel

Clean-Crete segments were applied for the first time in a new underground power transmission line project. CO2 emissions per segment ring were reduced from the conventional 588 kg to 199 kg, achieving an approximate 66.2% reduction.

Contributing to Traffic Congestion Relief in Urban Areas

Fukuoka City Subway Nanakuma Line

The section between the new Kushida Shrine-mae Station and Tenjin-Minami Station on the Fukuoka City Subway Nanakuma Line, which was extended and opened in March 2023, was constructed using the shield tunneling method. The project contributes to easing traffic congestion in Hakata City and, by extension, reducing CO2 emissions.

Excavation Underway Beneath Central Sapporo

Hokkaido Shinkansen Sasson Tunnel

Of the approximately 26.2 km long Sasson Tunnel, the roughly 8.4 km urban section on the Sapporo side is being constructed using the shield tunneling method. This approach is particularly well-suited for urban areas due to its ability to reduce noise and vibration during construction.

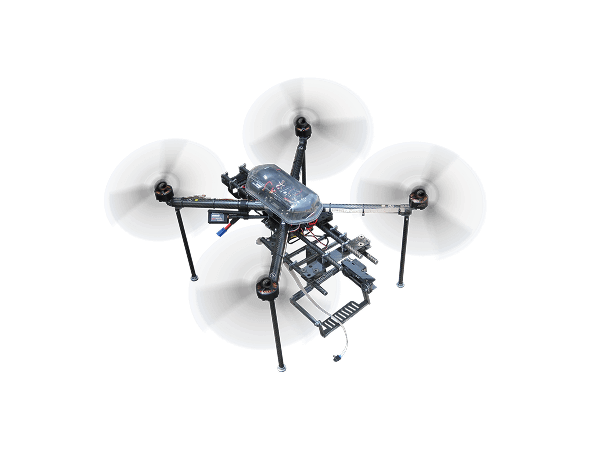

Collaboration Between Humans and Robots

Transporting. Building. Inspecting.

We’re beginning to foster collaboration

between people and robots

in a variety of construction scenarios.

- Promoting collaboration between humans and robots in readiness for skilled labor shortages.

-

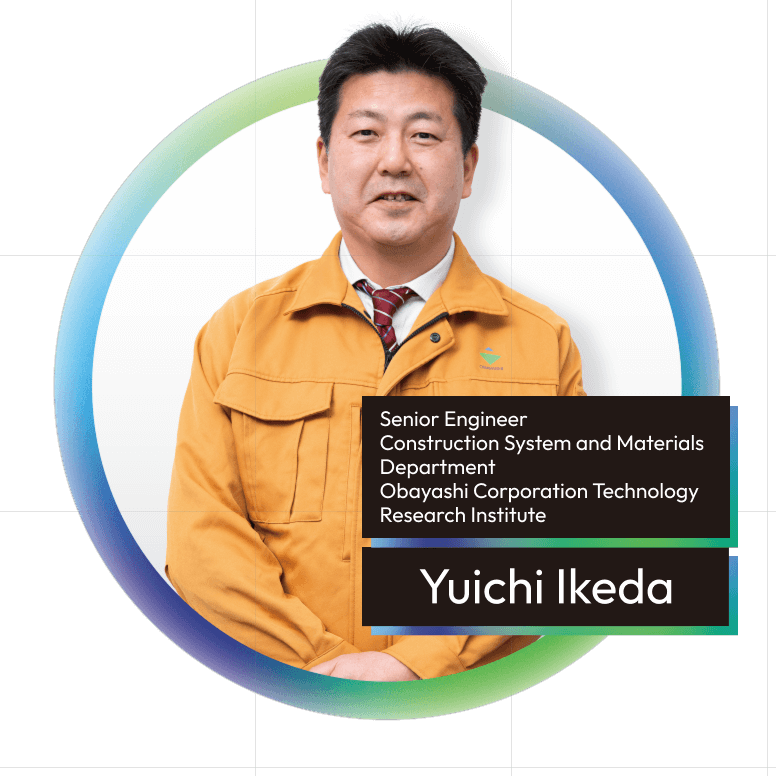

While entrusting dangerous tasks to robots is one approach, our perspective is, “Can we make robots true partners on site?” At Obayashi, we have a longstanding culture of dedicating significant time to on-site communication. By training AI with the practical expertise gained on the front lines of construction, we believe robots can become more flexible—almost human-like—in how they respond. Our goal is to design “work environments where both robots and people can work comfortably,” and to enhance productivity together.

A wide array of construction machinery,

robots, and digital technologies—

all connecting with people

to bring about major transformations on site.

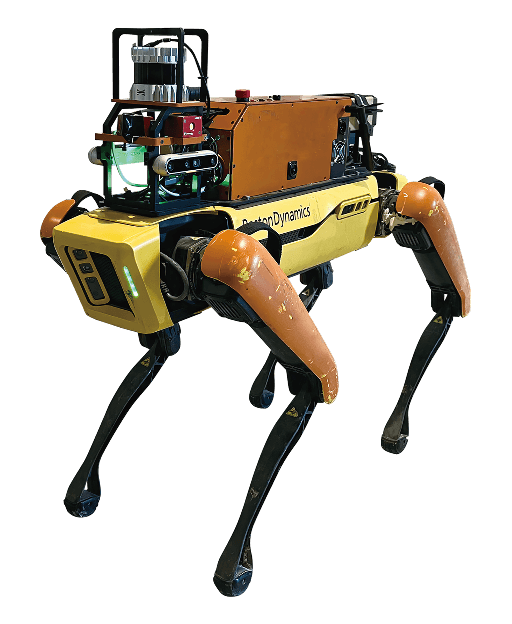

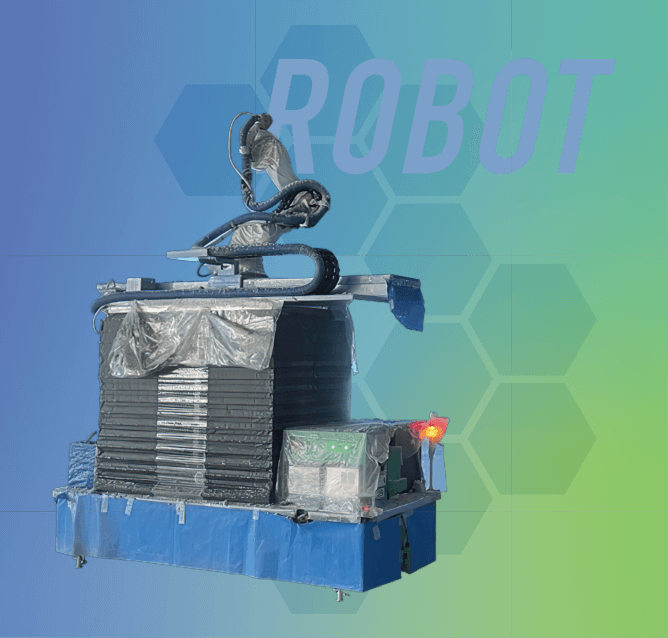

Robots are transforming construction by taking on tasks in place of people.

Achieve the same productivity and spraying quality as skilled workers

Fireproof Coating Spraying Robot

To protect steel frames in steel-structure buildings from fire damage, Obayashi has automated the fireproof coating spraying application process. The robot was specifically designed and developed to efficiently spray beams in office buildings. Both the productivity and spraying quality now reach the level of skilled workers.

Harnessing the power of digital technology to bring greater productivity and safety to construction sites

Visualizing work in advance with 3DCG

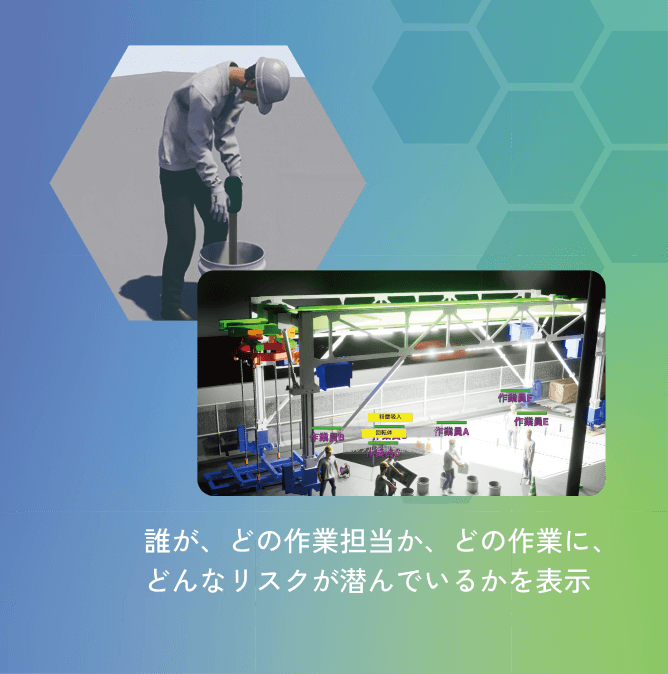

Construction Simulator

GEN-VIR*

GEN-VIR is a 3DCG-based construction work simulation technology jointly developed by Obayashi Corporation and Toyota Motor Corporation’s Frontier Research Center to reduce the physical fatigue on workers, improve productivity, and avoid risks. It recreates construction sites and worker movements in a virtual space, enabling detailed planning before actual work begins.

*GEN-VIR is a registered trademark of Toyota Motor Corporation.

Overlaying BIM and reality for quality control

MR Quality Management System holonica

holonica is a quality management system that overlays BIM data onto actual construction sites to perform inspections and verify work. By visualizing design information in 3D, it helps detect early signs of defects and improves efficiency by digitizing the entire workflow, including coordination with subcontractors.

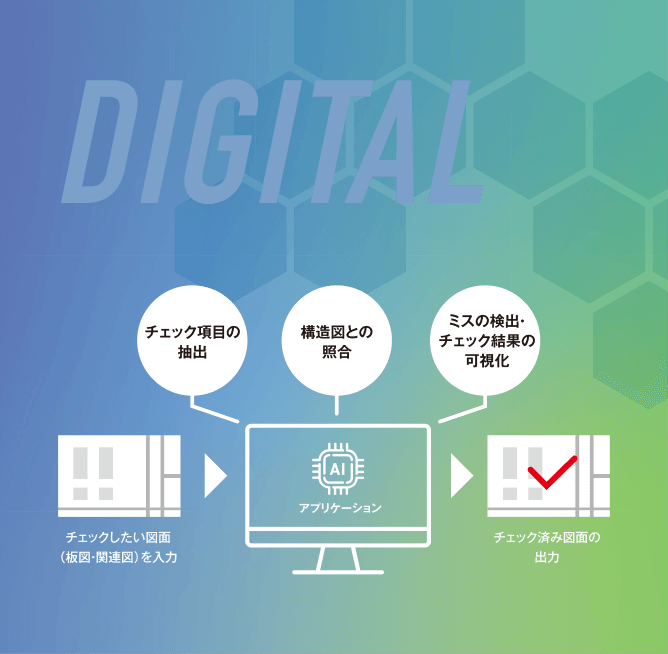

Automatic verification of panel drawings for the LRV method

AI-Based Drawing Verification System

Verification of construction drawings is a time-consuming task, and any oversight can lead to costly rework and major schedule delays. To address this issue, we developed a system that automatically verifies the coverage of structural drawings for precast (PCa) components used in the LRV method.

Over 10% reduction in heavy equipment operation time

Soil-Adhesion Prevention Component GeoDrop

By simply attaching a component made of fluoropolymer bonded to a steel plate onto an excavator bucket, GeoDrop effectively prevents soil from sticking. This reduces heavy equipment operation time by more than 10% and also contributes to lower CO2 emissions, reduced noise and vibration, improved productivity, and extended bucket lifespan.

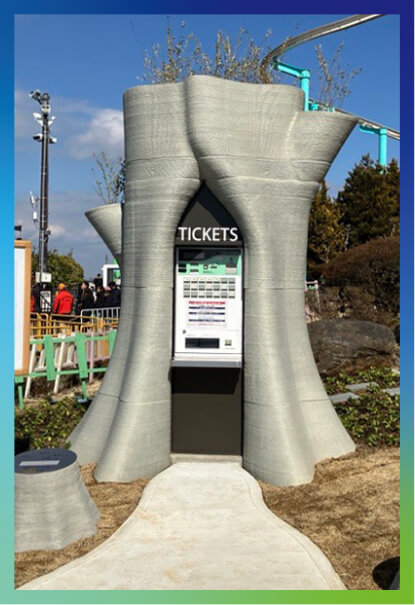

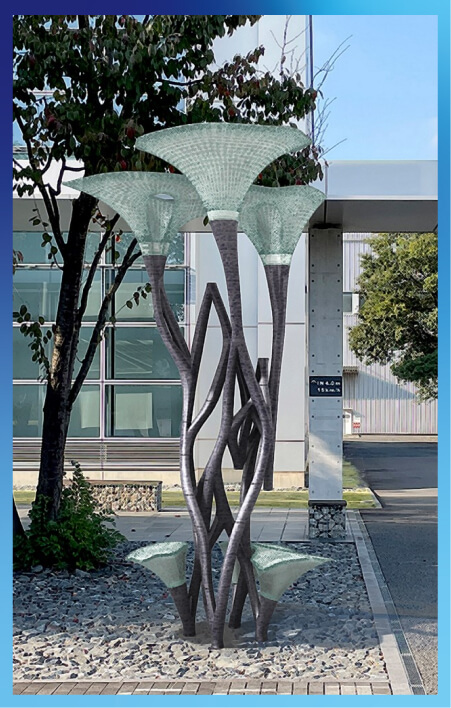

Construction 3D Printing

By utilizing 3D printers,

we reduce materials and manpower—

while also expanding the possibilities of design.

- We’re bringing free-flowing ideas

and fluid forms to life—

by printing them directly into society. -

3D printers are becoming increasingly familiar in everyday life, and they’re now starting to shine in the world of construction as well. They’re already making their mark in architecture, where distinctive design is essential, and also in civil engineering, where they excel at producing small quantities of highly customized components. Today’s cutting-edge technology allows for flexible control over the thickness of layered materials, making it possible to shape even freer, more expressive designs. As we explore this new way of “making,” new “things to make” are emerging too. We will continue to push the boundaries of this promising technology.

We’re using 3D printing

across a wide range of applications

to create entirely new forms

and previously difficult-to-build structures.

Fully 3D-printed architecture

3dpod

3dpod was constructed on the grounds of the OBAYASHI CORPORATION TECHNOLOGY RESEARCH INSTITUTE using a unique structural method in which a 3D-printed formwork is filled with Slim-Crete. It is the first building in Japan made with cement-based 3D printing materials to receive certification from the Minister of Land, Infrastructure, Transport and Tourism under the Building Standards Act.

Building with 3D printing

at OBAYASHI CORPORATION

TECHNOLOGY RESEARCH INSTITUTE

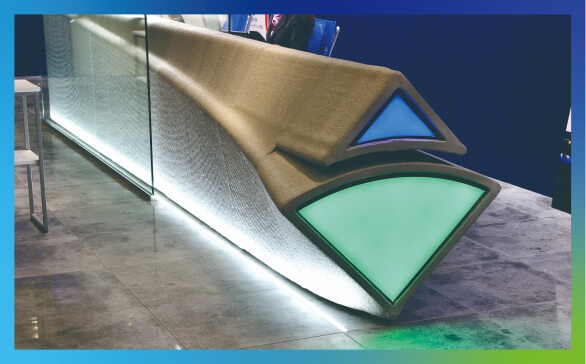

Reception Counter

at Osaka Main Office,

OBAYASHI CORPORATION

Creating beautifully streamlined benches

Yokohama Symphostage

– Outdoor Benches

Realizing complex

freeform structures

with a proprietary method

Ikomasanjo Amusement Park

– Ticket Booth

Toward full precast construction

with standard components

Shinmaruyama Dam

Construction Project –

Retaining Wall

First in Japan:

Application to a large-scale

civil engineering structure

R3 Submerged

Bedrock Type Groyne

on Seisho Coast

Expanding the possibilities

of construction 3D printing

Metal 3D Printing

We are pursuing the use of 3D printing technologies that utilize not only concrete but also metal materials in the construction field. Our goal is to develop technologies that can serve as alternatives to casting and support the production of a wide variety of components in small quantities.

See More-

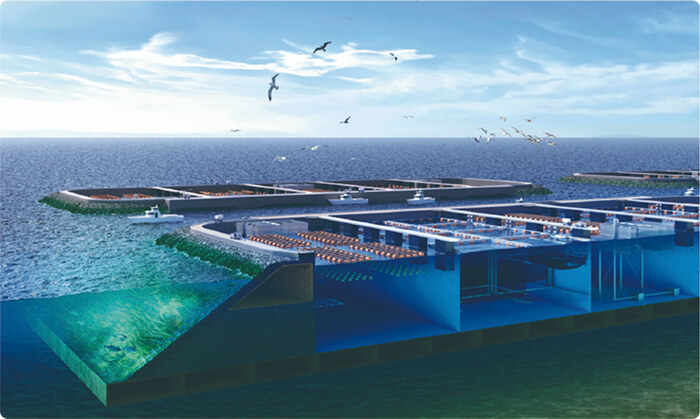

Chapter 02 VISION

Obayashi’s Vision for a Decarbonized Society

See MoreExplore the Obayashi Group’s wide-ranging visions and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of the construction industry. Themes include resource circulation, biodiversity, energy, and transportation infrastructure.

-

Chapter 03 CREATION

Realizing a Decarbonized Society and Creating New Social Value

See MoreExplore the many new value creation initiatives the Obayashi Group is making toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.