Please note that some content is only available in Japanese

Chapter 01 SOLUTION Low-Carbon Technologies and Initiatives in the Construction Process

SOCIAL PROBLEM Materials Development

- Our efforts begin with the decarbonization and carbon reduction of construction materials.

-

Steel and concrete—two of the most representative materials in construction.

They are widely used in buildings, bridges, dams, tunnels, and many other structures that surround our daily lives.

That’s because, for reasons such as strength, durability, and cost-effectiveness, using these materials is the most practical choice for construction.

However, both concrete and steel emit large amounts of CO2 during the manufacturing process.

That’s why we ask ourselves: “Can we create and use materials that produce less CO2?”

To decarbonize the construction process, we are addressing the challenge starting from the manufacturing stage of construction materials.

Concrete

The development theme:

Low-carbon concrete

that performs just like conventional concrete.

- No matter how advanced a material may be,

it’s meaningless if it’s not easy to use. -

Concrete fills our cities. Driven by the desire to dramatically reduce the CO2 emissions generated during its production, we developed Clean-Crete. By adjusting materials and mix proportions, we achieved the same workability and construction methods as conventional concrete. We also overcame the weakness of low-carbon concrete—its tendency to accelerate rebar corrosion due to faster carbonation—by developing a coating that slows this process. We’ve worked to expand adoption by overcoming differences in standards and regulations between building and civil engineering. Now, we are evolving the technology further—moving from simply reducing CO2 emissions to capturing and storing it.

If we can create materials

that are easy to use,

we believe we can contribute

to decarbonization.

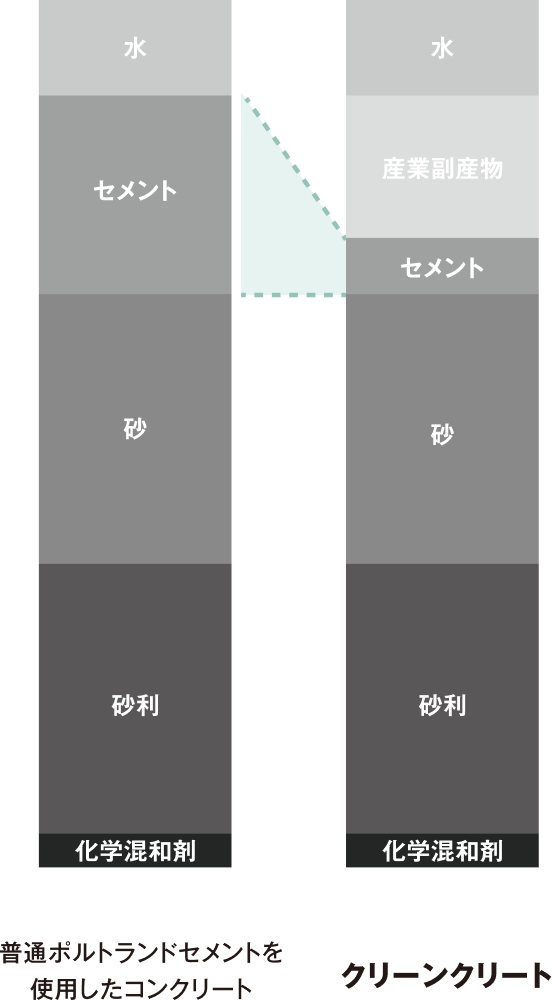

CO2 Reduction | Significantly cuts CO2 emissions while also meeting JIS standards.

Effective use of industrial by-products

Clean-Crete

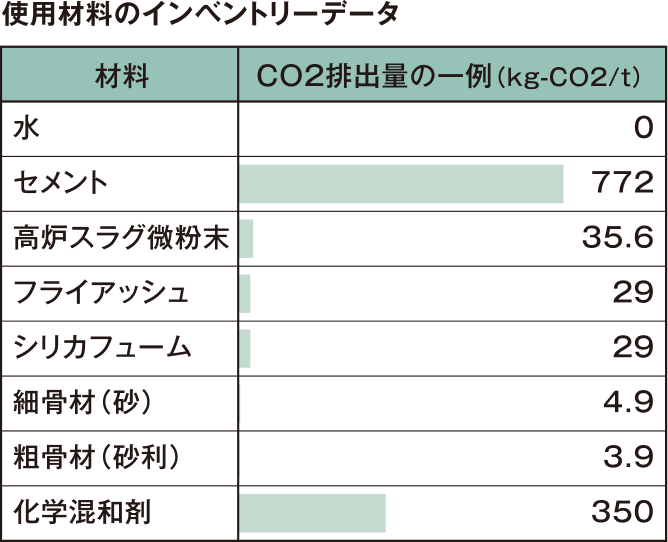

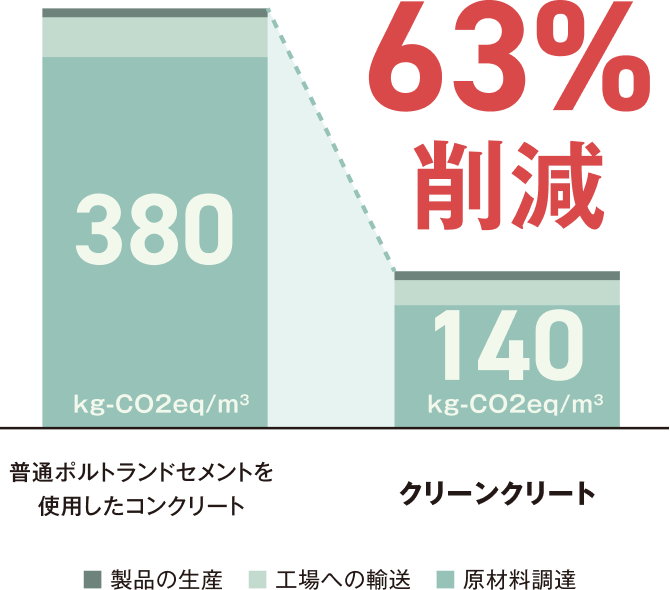

By replacing most of the cement with low-emission industrial by-products (such as ground granulated blast furnace slag and fly ash), Clean-Crete reduces CO2 emissions by up to 80% compared to conventional concrete.

- More than 60% of the cement replaced

-

- Environmental Product Declaration label SuMPO EPD obtained

-

It was verified through accurate third-party assessment that CO2 emissions can be reduced by 63% compared to concrete of the same compressive strength made with only ordinary Portland cement.

Leading the industry in placement volume and CO2 reduction

Largest use of Clean-Crete in domestic civil engineering

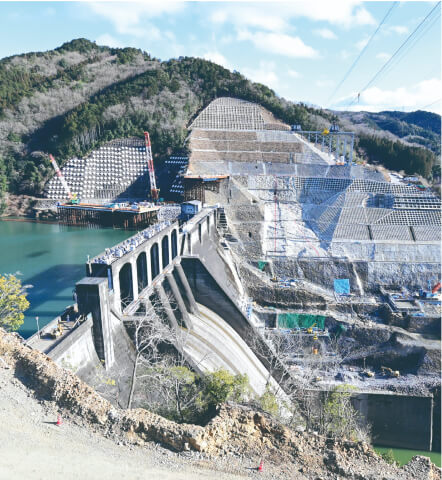

Shin-Maruyama Dam

In the Shin-Maruyama Dam construction project underway in Yaotsu Town and Mitake Town, Kamo District, Gifu Prefecture, approximately 15,500 m³ (design volume) of Clean-Crete was placed—making it the largest use of this material in a domestic civil engineering project. The resulting CO2 reduction is equivalent to the annual emissions from approximately 1,500 people’s households.

Clean-Crete was used in the construction of Shin-Maruyama Dam downstream cofferdam (left) and closure of the existing Maruyama Dam temporary drainage tunnel (right), as shown in orange

Record-breaking 90,000 m³ of Clean-Crete placed

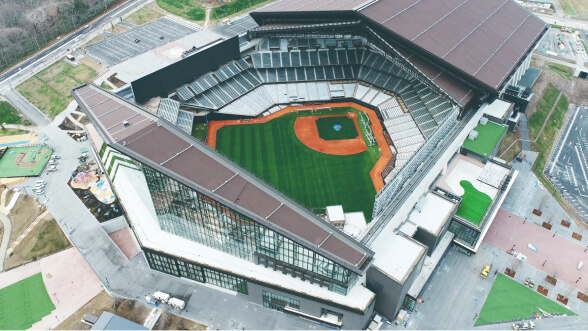

ES CON FIELD HOKKAIDO

Approximately 90,000 m³ of Clean-Crete was placed in the reinforced concrete girder structure supporting the retractable roof. In Hokkaido, where sourcing low-carbon concrete is challenging, this represents the largest application to date across both civil engineering and building construction.

Carbon Sequestration | Applicable to both precast products and cast-in-place construction

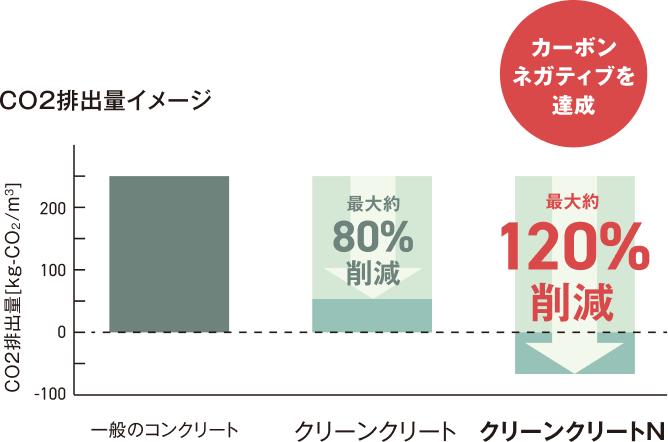

Achieving carbon negativity

Clean-Crete N

An advanced version of Clean-Crete, Clean-Crete N mixes in CCU powder, enabling the CO2 emissions to be reduced to zero (carbon neutral) or even further into the negative (carbon negative), depending on the amount of powder added.

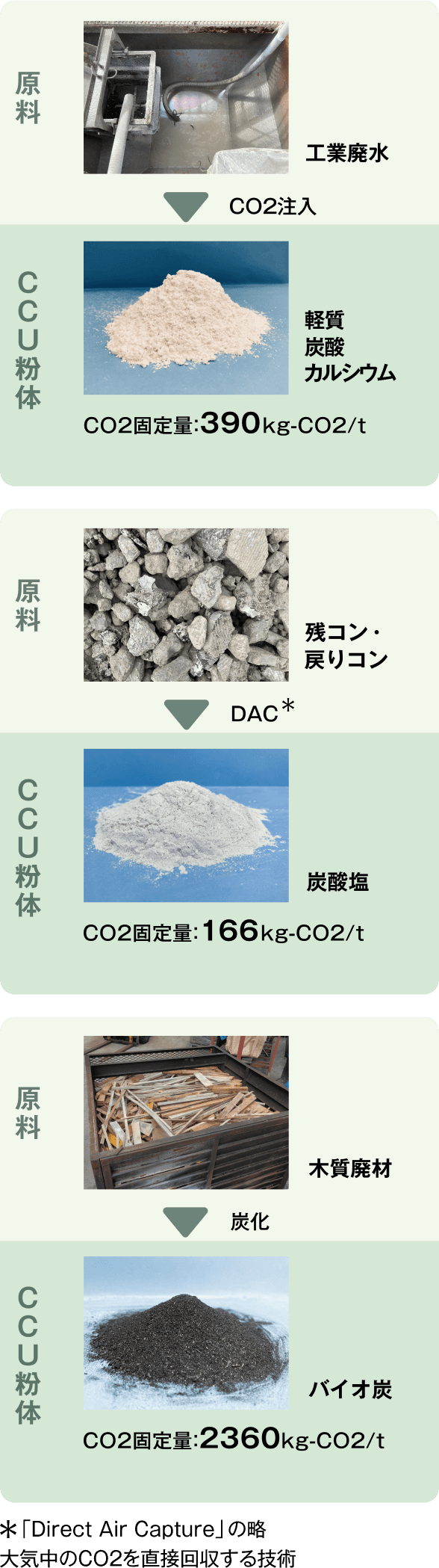

Use of CCU powder

CCU (Carbon Capture and Utilization) powder refers to powder that has absorbed and fixed CO2.

Carbon Sequestration | Materials for a wide range of structures

Fixing CO2 using woody biomass in concrete

Lignin-Crete

This concrete uses lignin, a type of woody biomass produced as a by-product of the papermaking process that uses wood. By adjusting the mix, it can fix an amount of CO2 within the concrete equivalent to the CO2 emitted during its production—enabling long-term storage directly in the concrete.

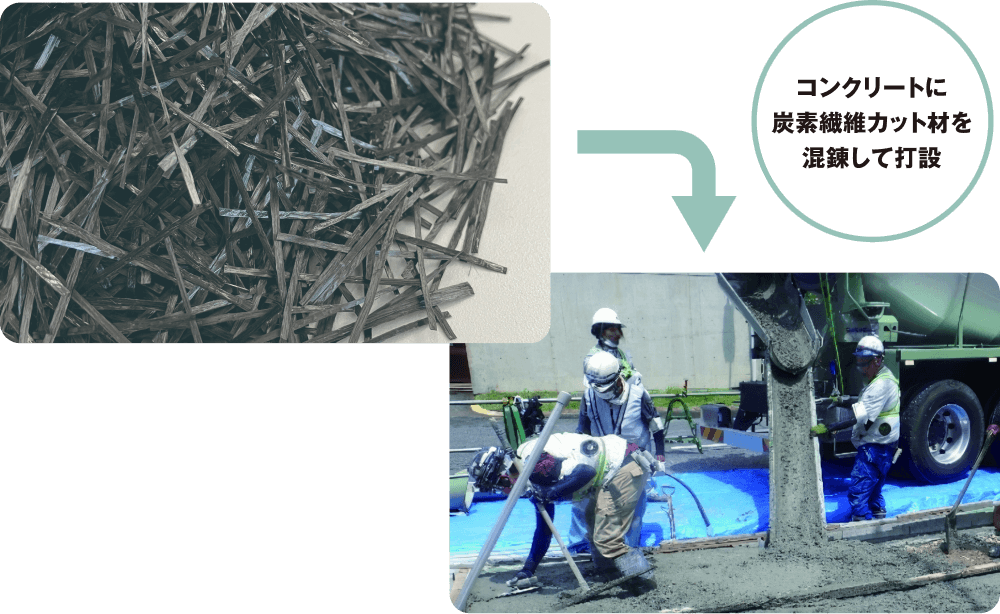

Recycled Fiber Materials | Enhancing concrete performance

Reducing rebar and CO2 emissions by using recycled carbon fiber

Recabo-Crete Method

Offcuts of carbon fiber reinforced plastic (CFRP) used in the hydrogen tanks of the fuel cell vehicle, TOYOTA MIRAI, are recycled into short fibers for concrete reinforcement, helping to reduce the need for rebar reinforcement. With just two-thirds the dosage of polypropylene fibers, they deliver equal or greater compressive strength and enhanced toughness, making the concrete more resistant to external forces.

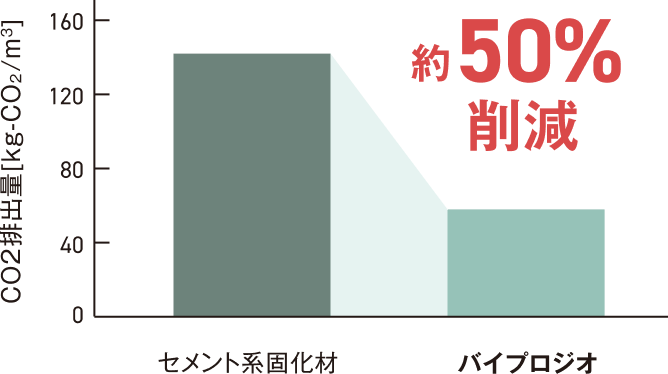

Ground Improvement Materials | Low-carbon, just like concrete

50% reduction in CO2 emissions from ground improvement work

By-pro Geo/Clean-Crete Geo

These ground improvement materials contribute to decarbonization. Their CO2 emission factor is approximately 50% of that of conventional materials. They also pose no risk of hexavalent chromium leaching, even in soils like Kanto loam, which are typically prone to such issues. With excellent strength development, the required strength can be achieved using roughly the same amount of additive as conventional methods.

60% reduction in CO2 emissions during manufacturing

Infill Hard Geo

By replacing factory-produced colloidal silica used in grout materials with naturally derived alternatives, we have achieved approximately a 60% reduction in CO2 emissions during manufacturing—while maintaining the same level of performance.

Resource Circulation and Recycling

Can we harness naturally occurring

inorganic resources for construction?

This material was born from

that spirit of exploration.

- With a mindset of

“What more can we do?”

we continue the research

for the best natural materials. -

Sealants used to fill joints and gaps in buildings, as well as exterior paints, generate a significant amount of CO2 emissions during manufacturing. We asked ourselves, “Could we reduce this by using natural materials?” That question led us to powder-made products by crushing shells. Through desk research and repeated testing with various types of shells, including abalone, clams, and oysters, we discovered that scallop shells showed the most promise.

Scallop shells are discarded in large quantities, posing a social issue—so finding a way to repurpose them is truly a win-win. That said, we don’t believe scallops are the final answer.Our research is far from over.

The raw material is discarded scallop shells—

and yet we were able to create a finishing material

that's just as effective as conventional products.

Giving discarded shells new life— as building materials

Finishing materials made with scallop shell powder

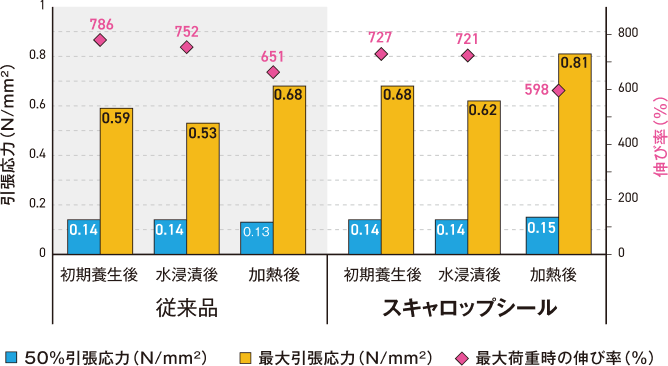

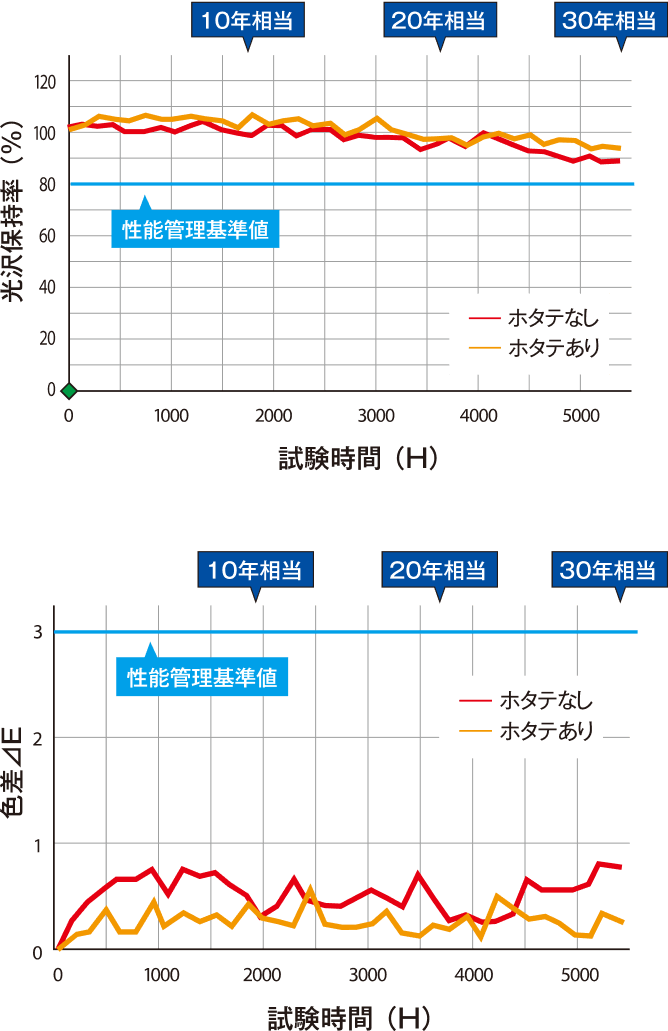

Scallop Seal / Scallop Paint

A biomass filler made from ground scallop shells is used as a substitute for calcium carbonate, which is commonly found in sealants for joints and in paints. As scallops grow, they absorb and trap CO2 from seawater in their shells, which helps reduce CO2 emissions during manufacturing.

-

Scallop Sealant Manufacturing Process

-

Scallop Seal Tensile Adhesion Test Results (JIS A 1439: Test Method for Building Sealants)

Both water resistance and heat resistance were equivalent to conventional products.

-

Scallop Paint Weather Resistance Test Results

There was virtually no change in gloss, and only minimal color change was observed.

Reusing Construction Waste

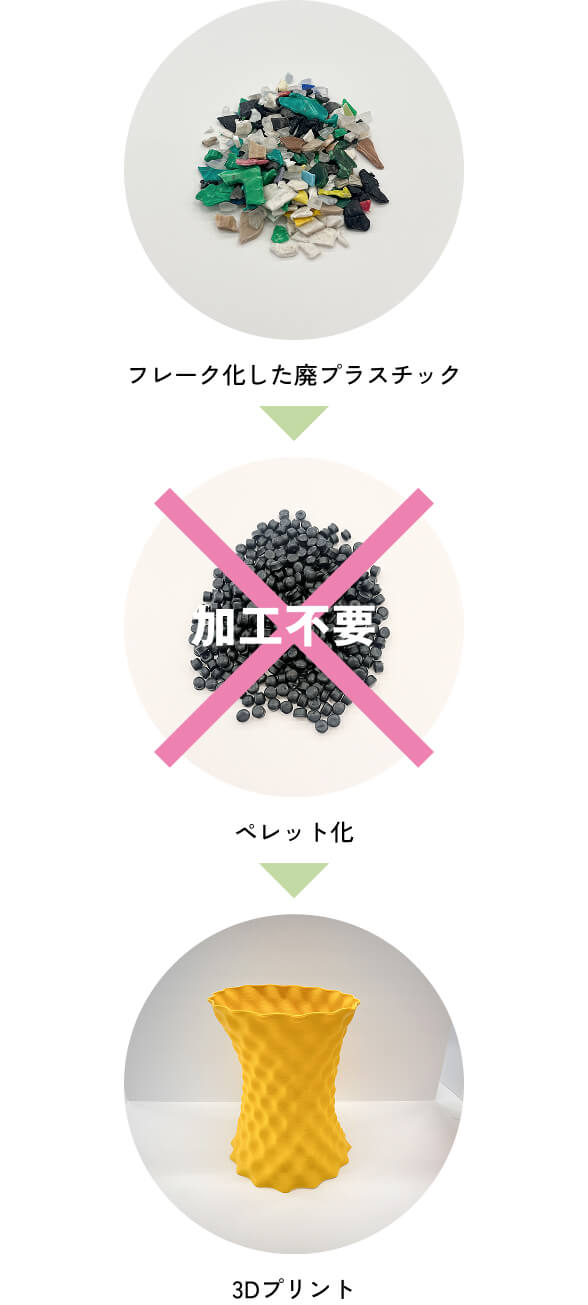

3D Printing Technology Using Recycled Plastic Waste

Plastic waste generated at construction sites is reused as raw material for 3D printing in flake form, without being pelletized.

This reduces both the energy and cost required for processing, while still allowing for print quality equivalent to that of pelletized material.

-

Chapter 02 VISION

Obayashi’s Vision for a Decarbonized Society

See MoreExplore the Obayashi Group’s wide-ranging visions and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of the construction industry. Themes include resource circulation, biodiversity, energy, and transportation infrastructure.

-

Chapter 03 CREATION

Realizing a Decarbonized Society and Creating New Social Value

See MoreExplore the many new value creation initiatives the Obayashi Group is making toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.