Please note that some content is only available in Japanese

MR-Based Quality Control System “holonica”

Overlaying BIM and reality to streamline inspections and construction checks

POINT

-

Completing inspection and correction workflows entirely in a digital environment

holonica overview video

holonica is a quality management system that overlays BIM data onto real construction sites for tasks such as construction checks and inspections.

Comments and defect reports can be recorded directly on the overlaid BIM data and shared in real time. Issues are displayed as digital pins in the mixed reality (MR) space, enabling smoother communication with other workers and greatly reducing oversights and misunderstandings.

With just one click, correction instructions can be issued to subcontractors, who can then check the details and submit reports via smartphone. This allows the entire workflow for quality control and final inspections to be completed digitally. -

Visualizing BIM data on-site and accessing finish details in real time

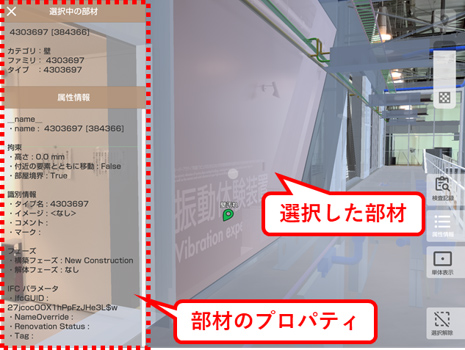

Tablet screen example

By visualizing design information in 3D, users can immediately identify discrepancies in shapes, helping detect potential issues early. At the same time, users can access detailed information embedded in the BIM data—such as part IDs, cross-sectional dimensions, finish specifications, and product data—allowing for construction management that goes beyond shape inspection, all within a single system.

-

Also applicable for various construction checks and layout marking

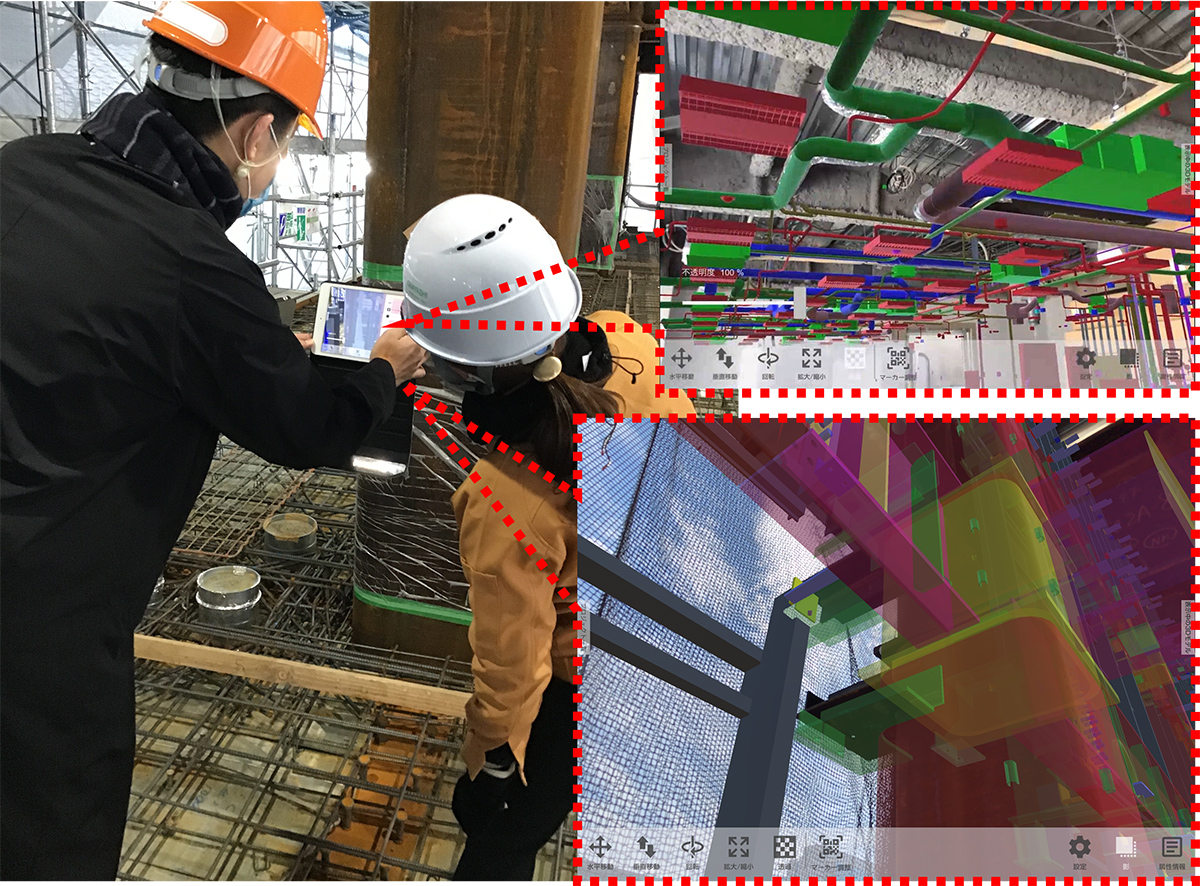

Example use of MR technology

holonica can be used not only for inspections but across a wide range of construction management tasks. For example, by overlaying post-pour BIM data (structural model) onto a site before concrete placement, users can check the location and quantity of sleeves and openings, and verify reinforcement placement. It can also be applied to layout work where slight deviations are acceptable, such as for pile head reinforcement, ceiling inserts, or contaminated soil areas. Moreover, it can be used in steel product inspections and even at groundbreaking ceremonies, delivering benefits to subcontractors, designers, supervisors, and clients alike. It’s a system that broadly supports construction sites across various phases and stakeholders.