Please note that some content is only available in Japanese

Energy-Saving Shield

Achieving high-speed excavation and energy savings with a double cutter method

POINT

-

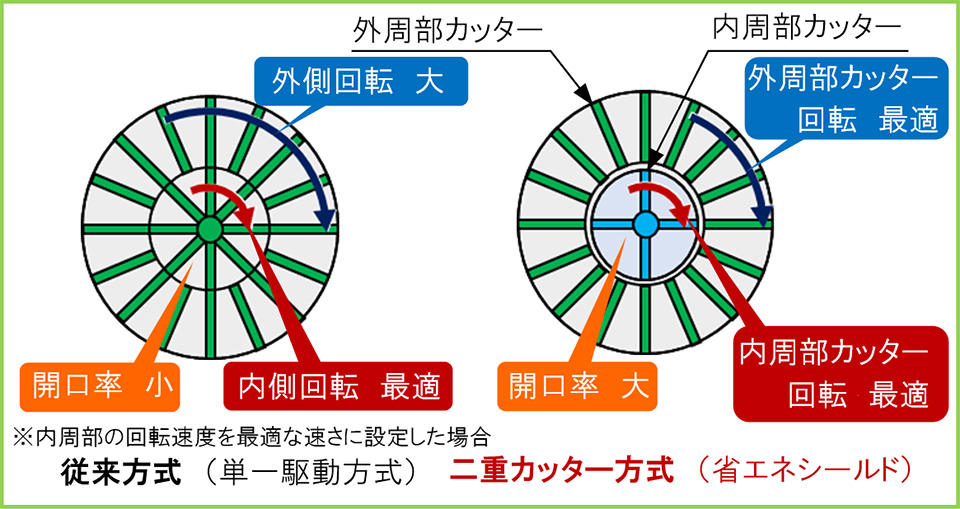

Individually optimized rotation speeds for outer and inner sections

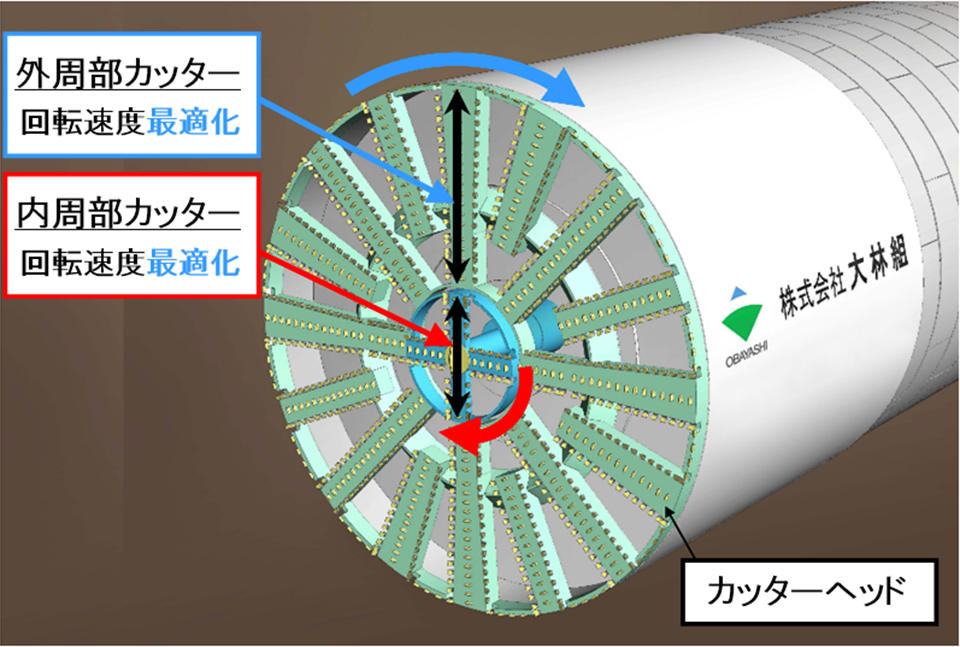

Exterior view of the Energy-Saving Shield

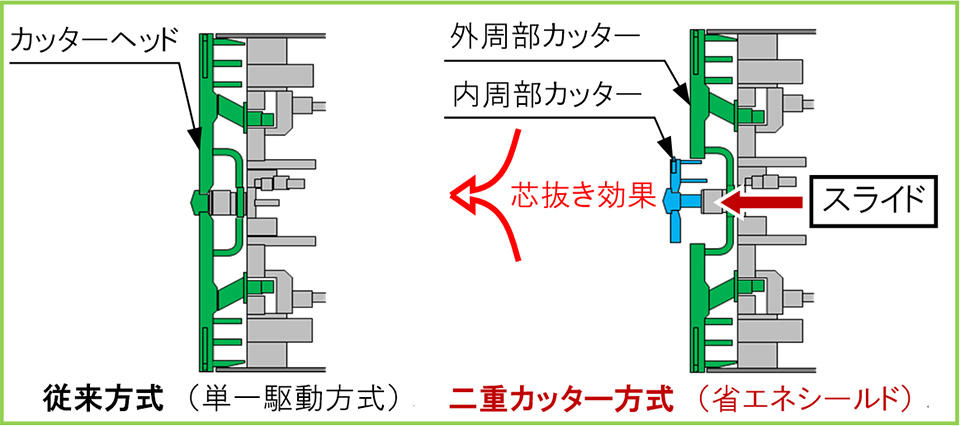

This shield machine adopts a double cutter method, in which the cutter head at the front is divided into outer and inner sections that rotate independently. By allowing separate optimization of the rotation speeds for each section, the system enables efficient excavation. This leads to high-speed tunneling and reduced power consumption, especially for large-diameter tunnels.

-

Exterior view of the Energy-Saving Shield

-

Front view of cutter section

-

Cross-sectional view of cutter section

-

Improved excavation speed and accuracy contribute to shorter construction periods

By optimizing rotation speeds, the system reduces the cutter bit penetration depth and utilizes a pilot-boring effect from the inner section’s advance excavation to lower cutter torque and thrust force. This results in approximately 25% faster excavation. In addition, by preventing soil adhesion to the center of the cutter, it ensures stable excavation and improves operating efficiency. These benefits contribute to a shorter overall construction period. Optimizing the outer cutter’s rotation speed and shortening the construction period also lead to about a 30% reduction in power consumption for shield machine operation, cutting costs

-

Stabilizing the tunnel face helps to suppress ground deformation

By adjusting the cutter rotation speed, the system enhances the soil-mixing performance within the chamber, ensuring adequate plastic flow. This contributes to greater tunnel face stability and helps suppress ground deformation.