Please note that some content is only available in Japanese

Technologies and Initiatives Related to Low Carbon

From material production to construction, operation, renovation, and demolition—this chapter introduces the Obayashi Group’s technologies, initiatives, and real-world examples aimed at minimizing CO2 emissions at every stage of the construction process.

-

Chapter 01-1Materials Development

-

Chapter 01-2Construction

-

Chapter 01-3Operation and Renovation

-

Chapter 01-4Demolition

-

Chapter 01-1 Materials Development

-

Clean-Crete

Environmentally friendly concrete utilizing industrial by-products

-

Clean-Crete N

Achieving net-zero—and even negative—CO2 emissions during production

-

Lignin-Crete

Decarbonization-supporting concrete made with woody biomass

-

Recabo-Crete Method

Reusing CFRP offcuts as short fibers to reinforce concrete and reduce rebar usage

-

By-pro Geo / Clean-Crete Geo

Reducing CO2 emissions from ground improvement work by 50%

-

Infill Hard Geo

Grouting material for ground improvement—reduces CO2 emissions during production by 60%

-

Scallop Seal / Scallop Paint

Sealant and paint made with powdered scallop shells

-

3D Printing Technology Using Recycled Plastic Waste

Used in flake form as raw material for 3D printing

-

-

Chapter 01-2 Construction

-

Remote Crane Operation

Utilizing Digital Twins to achieve safe and efficient crane operations

-

Remote Construction for Dam Embankment and Chimney Demolition

Safe and efficient heavy machinery operations

-

Use of Battery-Powered Large Electric Construction Equipment

First on-site deployment of a 20-ton class battery-powered hydraulic excavator in Japan

-

Utilization of Biodiesel Fuel

Use of biodiesel fuel at construction sites to reduce CO2 emissions from diesel oil

-

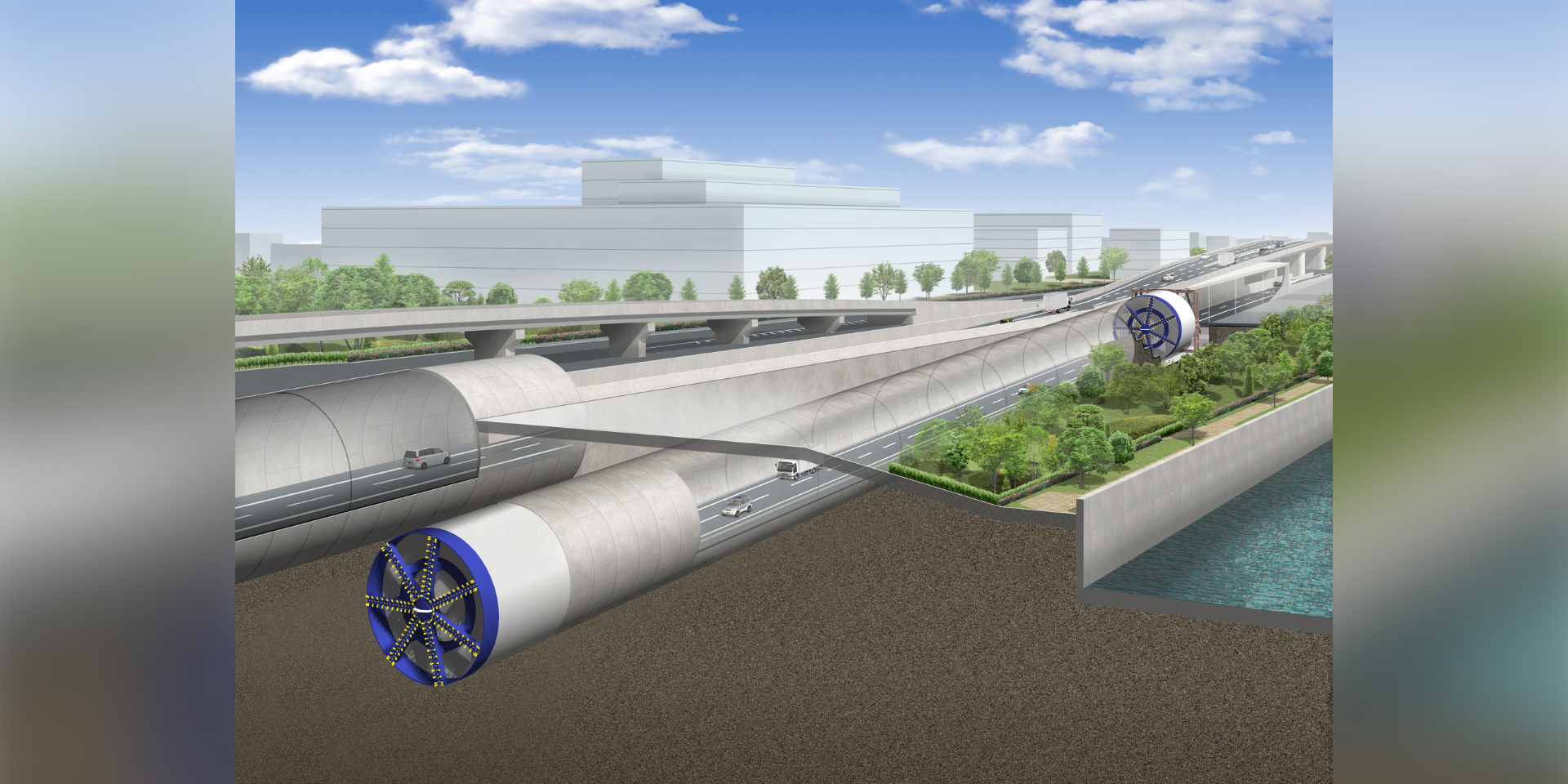

OGENTS

Automating various shield tunneling operations

-

Energy-Saving Shield

Achieving high-speed excavation and energy savings with a double cutter method

-

Carbon-Neutral Backfill Grouting Material

Reducing CO2 emissions during shield tunnel construction to net-zero or below

-

Clean-Crete Segments

Environmentally friendly segments with significantly reduced CO2 emissions

-

URUP Method

Significantly reducing CO2 emissions through ground-level launch and arrival

-

Fireproof Coating Spray Robot

Achieve the same productivity and spraying quality as skilled-workers

-

Construction Simulator GEN-VIR*

*GEN-VIR is a registered trademark of Toyota Motor Corporation.Visualizing work in advance with 3DCG to optimize processes and worker movements

-

MR-Based Quality Control System “holonica”

Overlaying BIM and reality to streamline inspections and construction checks

-

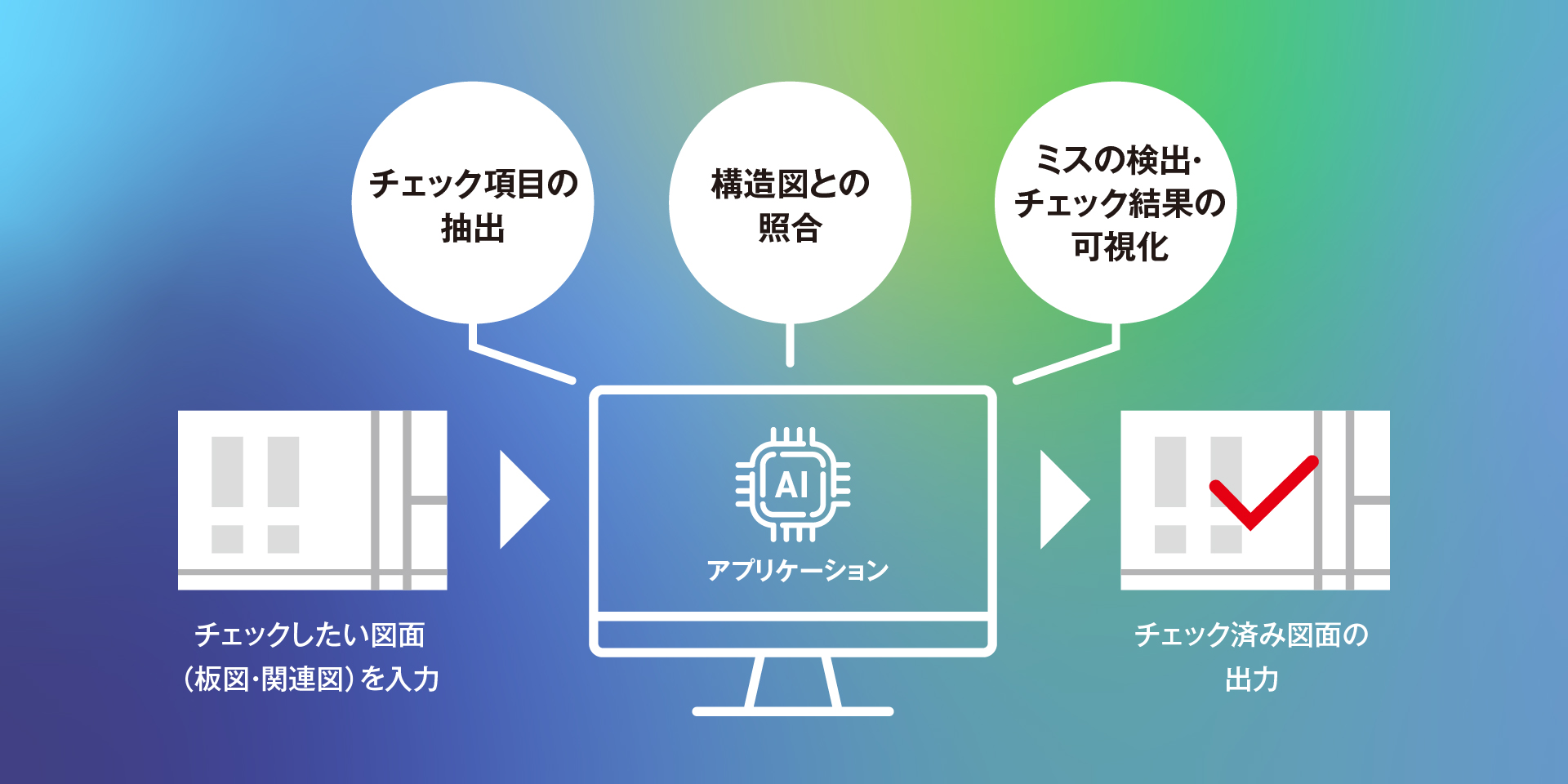

AI-Powered Drawing Verification System

Automatically checking structurally critical areas of LRV construction

-

Soil-Adhesion Prevention Component “GeoDrop”

Reduces heavy equipment work time by over 10%, contributing to CO2 emission reduction

-

3D Printing in Architecture

Turning free-form design ideas directly into reality

-

3D Printing in Civil Engineering

Enhancing safety and construction quality while shortening the project timeline

-

Metal 3D Printing

Expanding the possibilities of construction 3D printing with metal materials

-

-

Chapter 01-3 Operation and Renovation

-

Carbon Design Tool “E-CO BUILDER”

Supporting evaluation of investment effectiveness toward carbon neutrality

-

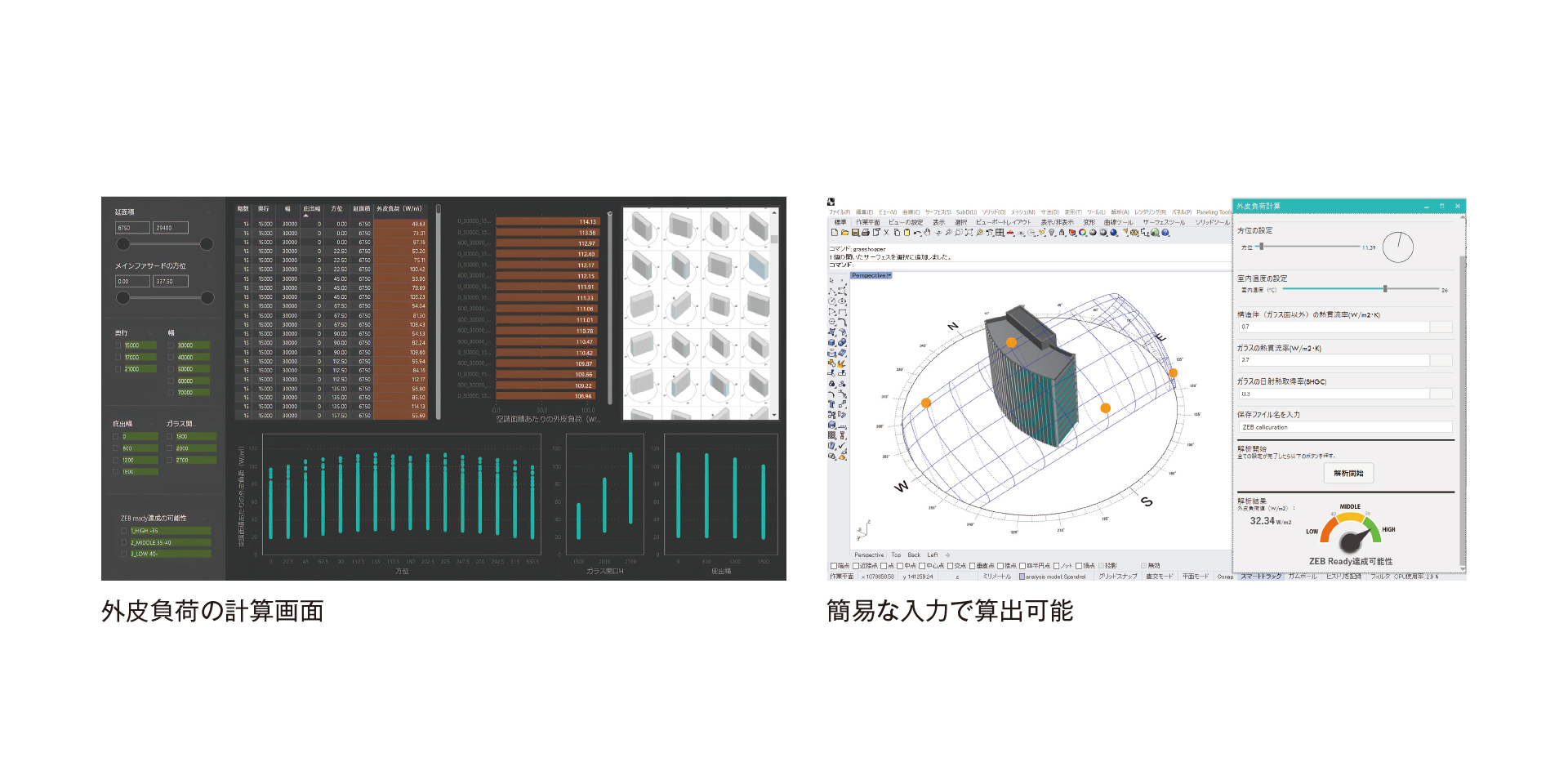

Simplified ZEB Ready Evaluation System

Quick and highly accurate evaluation using simplified building envelope load estimates

-

Smart Building Service

Managed Built Environment Service (M-BES)

-

Managed ESG Service

ESG Building Management solutions

-

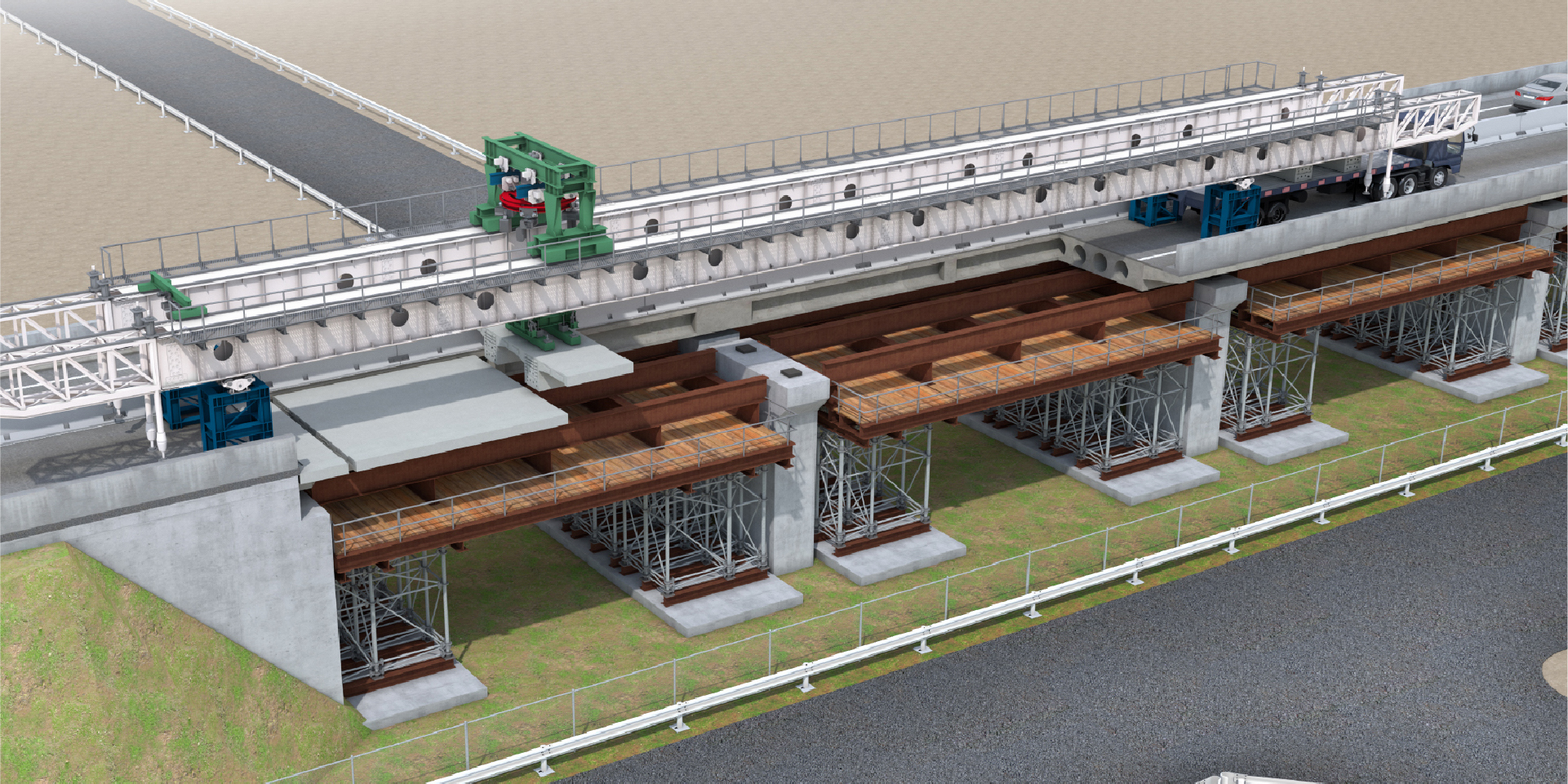

DAYFREE

Replacing highway bridge decks with just one lane closed at night

-

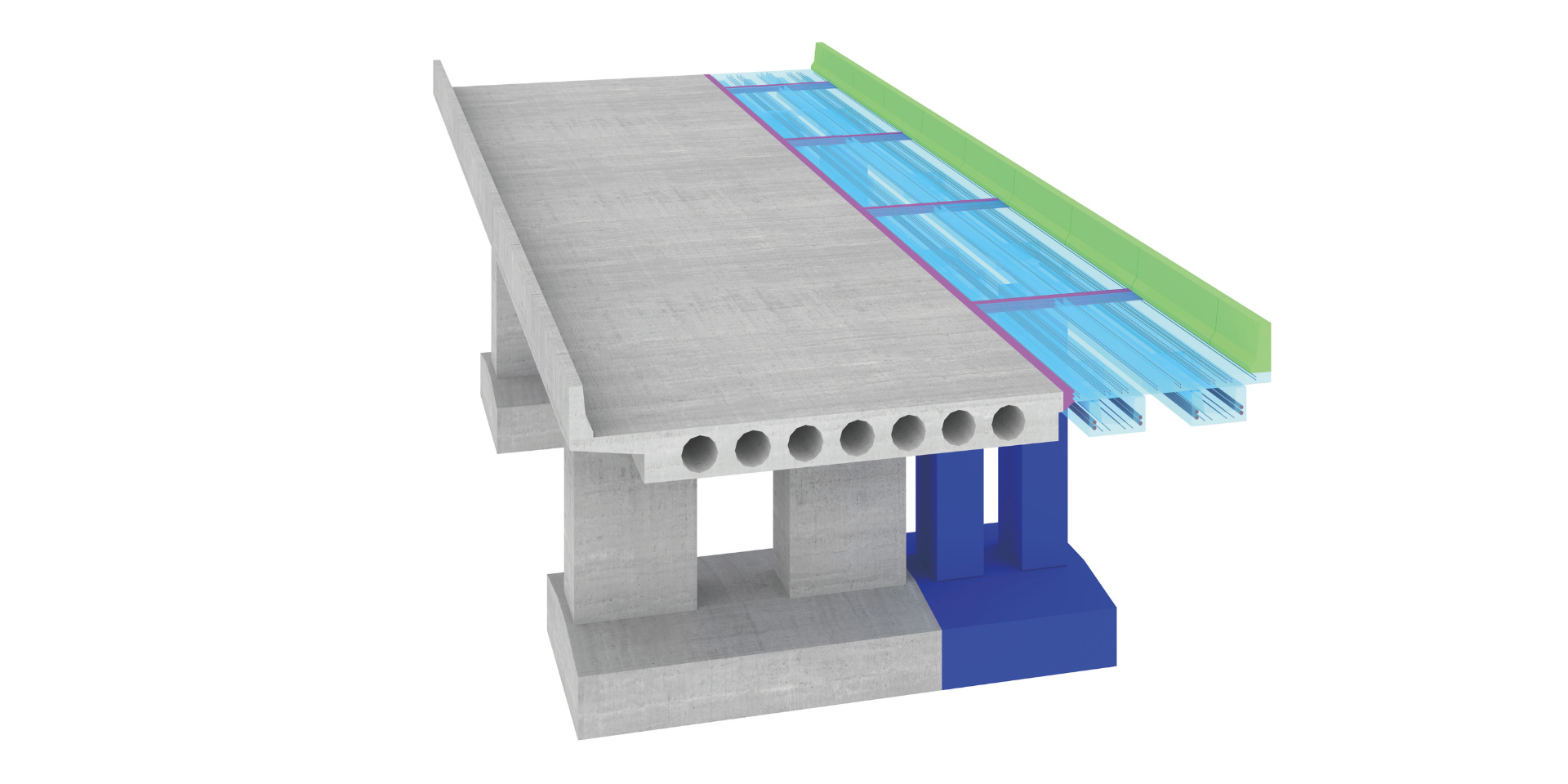

HOLLOWAL

Replacing hollow slab bridges in half the time

-

PC Wider

Bridge widening using PCa-U girders for concrete bridges

-

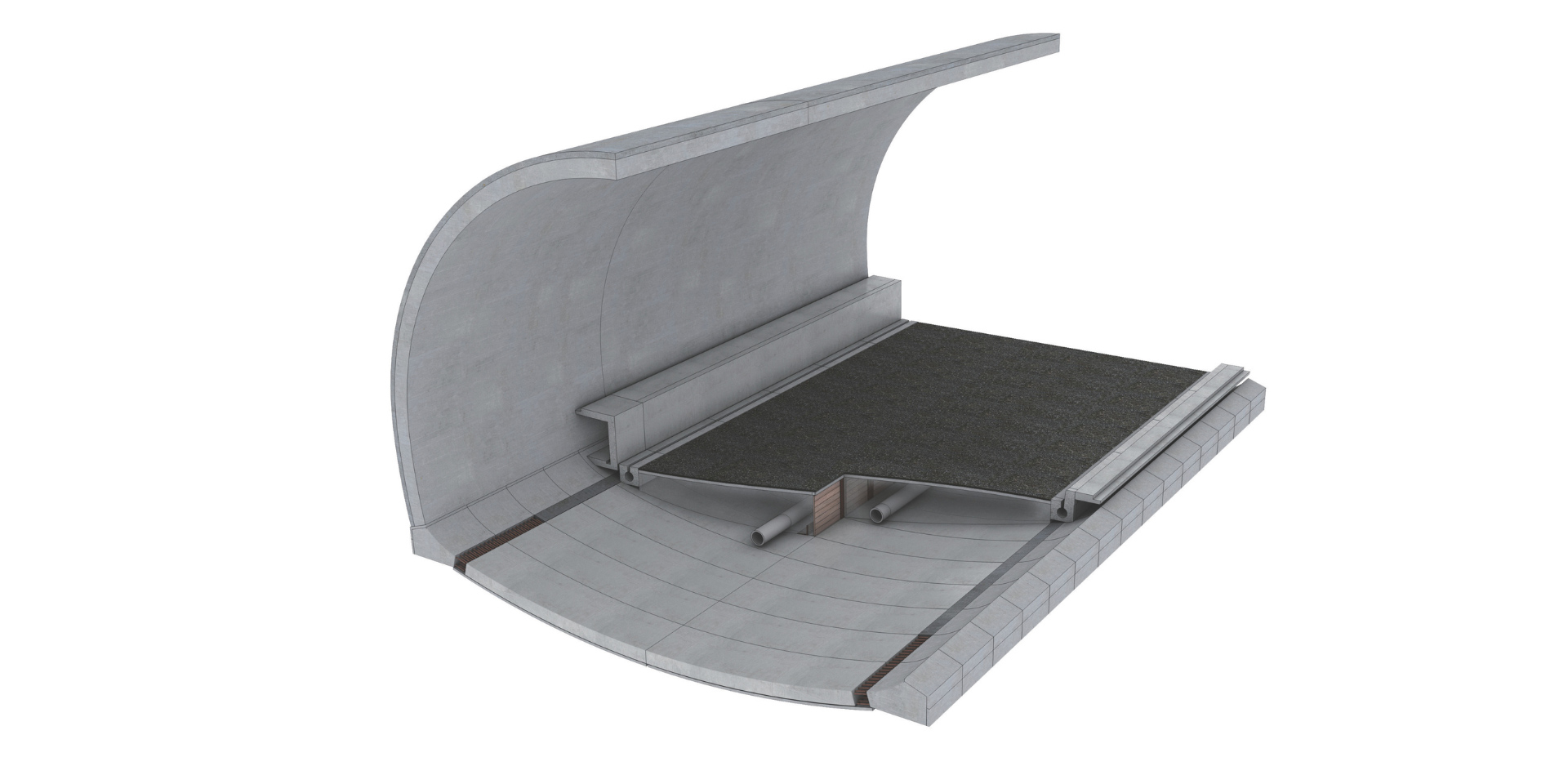

Compact Invert

Rapid invert construction using precast components

-

One-Bind Cross

Faster, higher-quality reinforcement of tunnel linings

-

Stiff-Crete

Achieving both early traffic reopening and highly durable deck reinforcement

-

-

Chapter 01-4 Demolition