Please note that some content is only available in Japanese

Chapter 02 VISION Obayashi’s Vision for a Decarbonized Society

Explore the Obayashi Group’s broad-ranging concepts and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of construction.

Themes include resource circulation, biodiversity, energy, and transportation infrastructure.

Circular Timber

Construction

Contributing to a decarbonized, circular, and nature-symbiotic society through the sustainable use of forest resources—toward a future that circulates with wood.

- LOOP50

- The Future of Circular Timber Construction

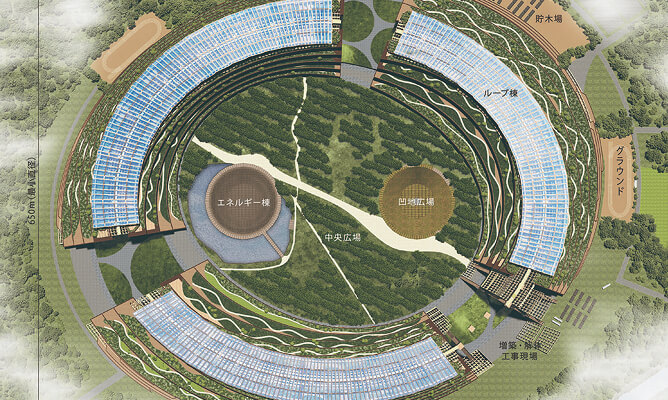

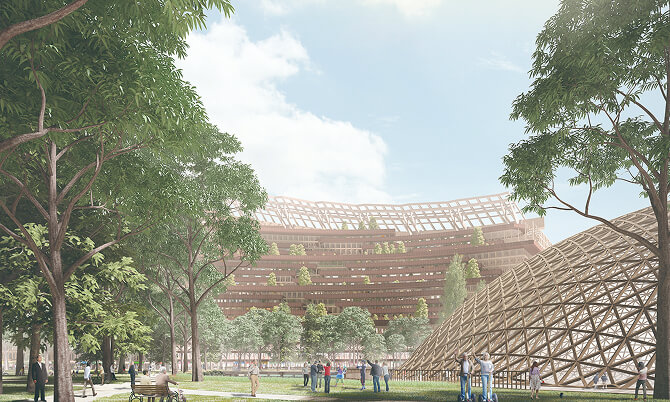

A Wooden, Circular City Living in Harmony with the Forest

- Circular Use of Forest Resources

- Using timber grown over 50 years in local forests, one section is added each year and dismantled after 50 years of use—creating a symbiotic city that grows in harmony with the forest through continuous circulation.

- Energy Self-Sufficiency

- Dismantled buildings are reused and recycled, and ultimately used as an energy source for the city in a biomass plant.

- Collaboration with Local Communities

- Infrastructure is renewed alongside buildings. The use of timber helps sustain the multifaceted functions of forests and contributes to revitalizing local communities.

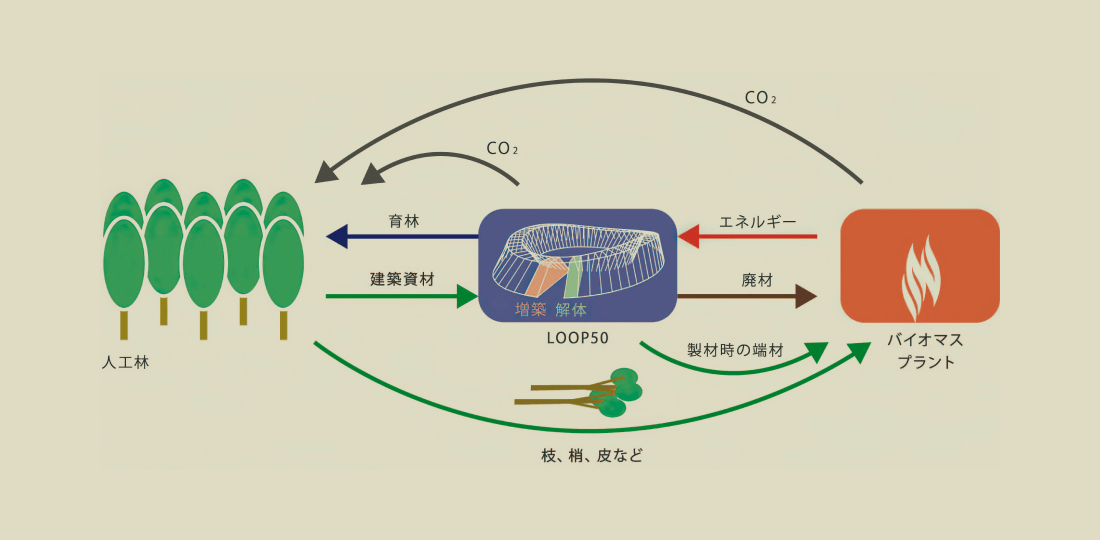

The Circular Use of Timber

is also the Circular Flow of CO2 (Carbon Dioxide)

Trees absorb CO2, and even after being harvested and turned into timber, they continue to store carbon. For this reason, timber is often referred to as "carbon storage." CO2 is only released back into the atmosphere when the timber is burned through thermal recycling, but by then, newly planted and grown trees will absorb it again. Continuously cycling through "growing," "producing," "using," "reusing," and "fully utilizing" timber helps maintain the fixation of CO2 in the atmosphere, leading to decarbonization. At Obayashi Corporation, this circular flow of timber use and CO2 fixation is called Circular Timber Construction (CTC) as part of our commitment to building a nature-symbiotic society.

-

- Grow

- Clear-cutting and reforestation are essential for the sustainable use of planted forests. Obayashi Corporation has developed a hybrid artificial light seedling production system that operates independently of weather conditions, and installed a pilot plant in Nichinan Town, Tottori Prefecture. This contributes to the stable supply of larch seedlings. These efforts, along with the sustainable forest management of company-owned forests, were recognized with the Excellence Award (Director-General of the Forestry Agency Award) in the “Forests × ACT Challenge 2024.”

-

- Produce

- The Obayashi Group promotes the expansion of the timber supply chain through wood processing carried out by its group companies, CYPRESS SUNADAYA and NAIGAI TECHNOS, which supply timber not only for in-house use but also to many external companies.

Processing into various types of timber

One of the leading CLT manufacturers in Japan

CYPRESS SUNADAYA

Experts in woodworking technology

NAIGAI TECHNOS-

Aligning laminated boards

-

Crossing the grain

direction, layering, and bonding them together -

Cross-Laminated Timber (CLT)

-

- Use

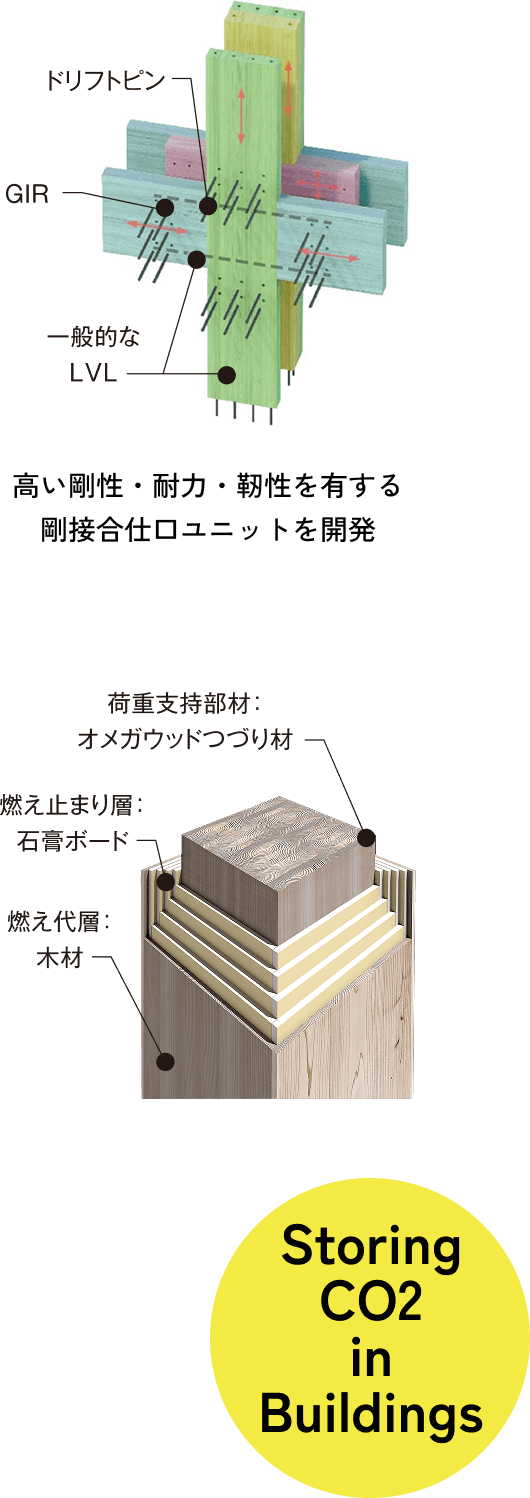

- Since timber continues to store CO2 even while being used as a building material, timber structures are often called “the second forests of the city.” Additionally, compared to steel and concrete, timber produces significantly less CO2 emissions during manufacturing, thus contributing to decarbonization. Obayashi Corporation is also developing a variety of timber construction technologies to promote the broader use of timber.

-

- Reusing

- Timber that has reached the end of its life as a building material is repurposed for other uses, continuing to store carbon. At Obayashi Corporation, reused timber has been adopted for the interior of the Osaka Head Office Building. A temporary wooden site office used and dismantled at a project site in Kobe is also being reused at a site in Yokohama from April 2025. In addition, timber is being used for parts of temporary fencing, with plans for future reuse.

-

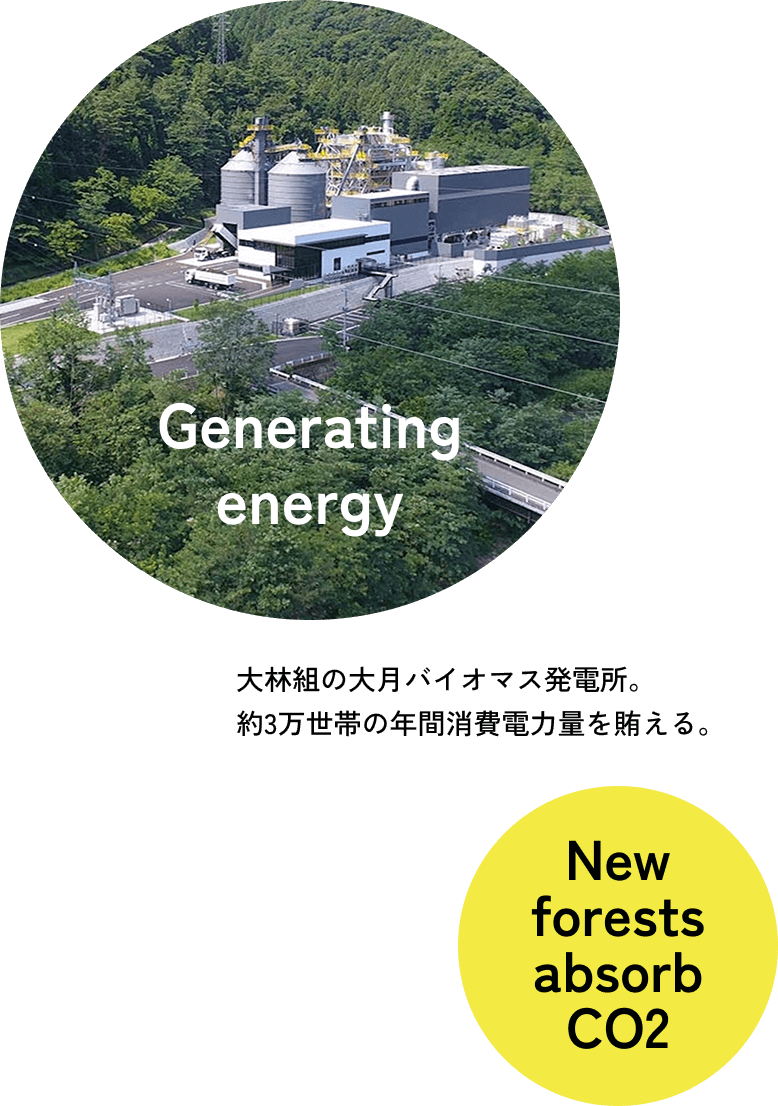

- Using up

- Wood that can no longer be used or reused is ultimately utilized as fuel for biomass power generation. Obayashi owns two biomass power plants in Japan. The Otsuki Biomass Power Plant (located in Otsuki City, Yamanashi Prefecture) uses only domestically sourced wood-based fuel and has a generation capacity of 14.5 MW, enough to supply the annual electricity needs of approximately 30,000 households. A portion of the resulting ash is reused as base course material or backfill material, further contributing to resource circulation.

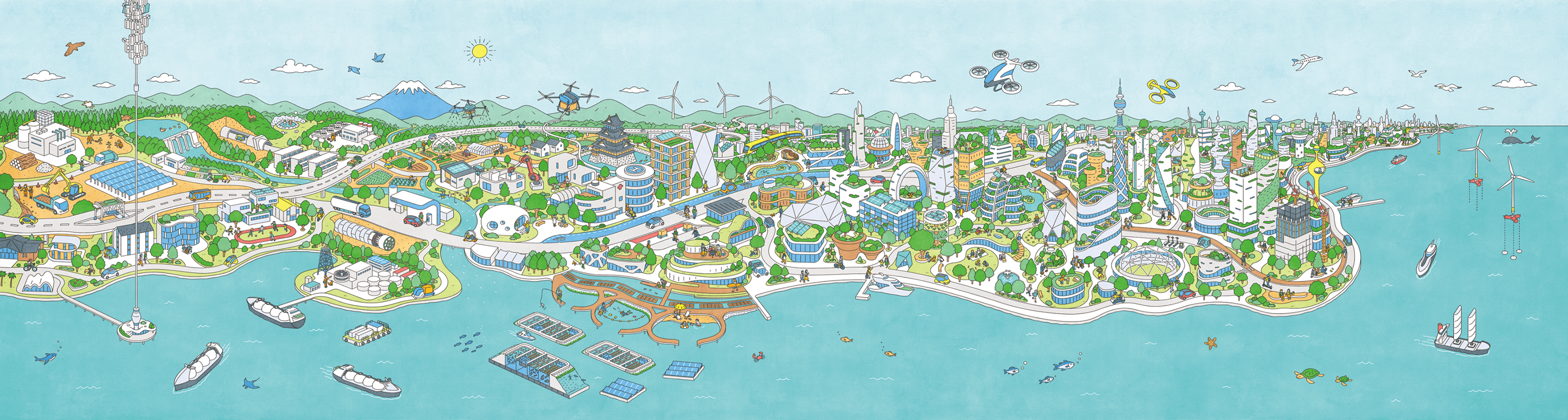

Decarbonization VISION MAP

- Green Infrastructure

-

- Zero-Emissions Energy

-

- Next-Generation Transportation Infrastructure

-

-

Chapter 01 SOLUTION

Low-Carbon Technologies and Initiatives in the Construction Process

See MoreFrom material production to construction, operation, renovation, and demolition—this chapter introduces the Obayashi Group’s technologies, initiatives, and real-world examples aimed at minimizing CO2 emissions at every stage of the construction process.

-

Chapter 03 CREATION

Realizing a Decarbonized Society and Creating New Social Value

See MoreExplore the many new value creation initiatives the Obayashi Group is making toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.