Please note that some content is only available in Japanese

Chapter 01 SOLUTION Low-Carbon Technologies and Initiatives in the Construction Process

SOCIAL PROBLEM Operation

- We visualize energy consumption during building use to reduce “lifetime CO2 emissions.”

-

To live comfortably in today’s society, we rely heavily on systems like heating, cooling, and IoT devices—leading to ever-increasing energy use during a building’s operational phase.

If nothing is done, the building’s lifetime CO2 emissions will grow significantly.

How much energy is being consumed each day? What actions are needed to reduce it?

The first step is understanding. By advancing visualization technologies, we’re working not only to reduce emissions during construction, but also to decarbonize buildings throughout their use.

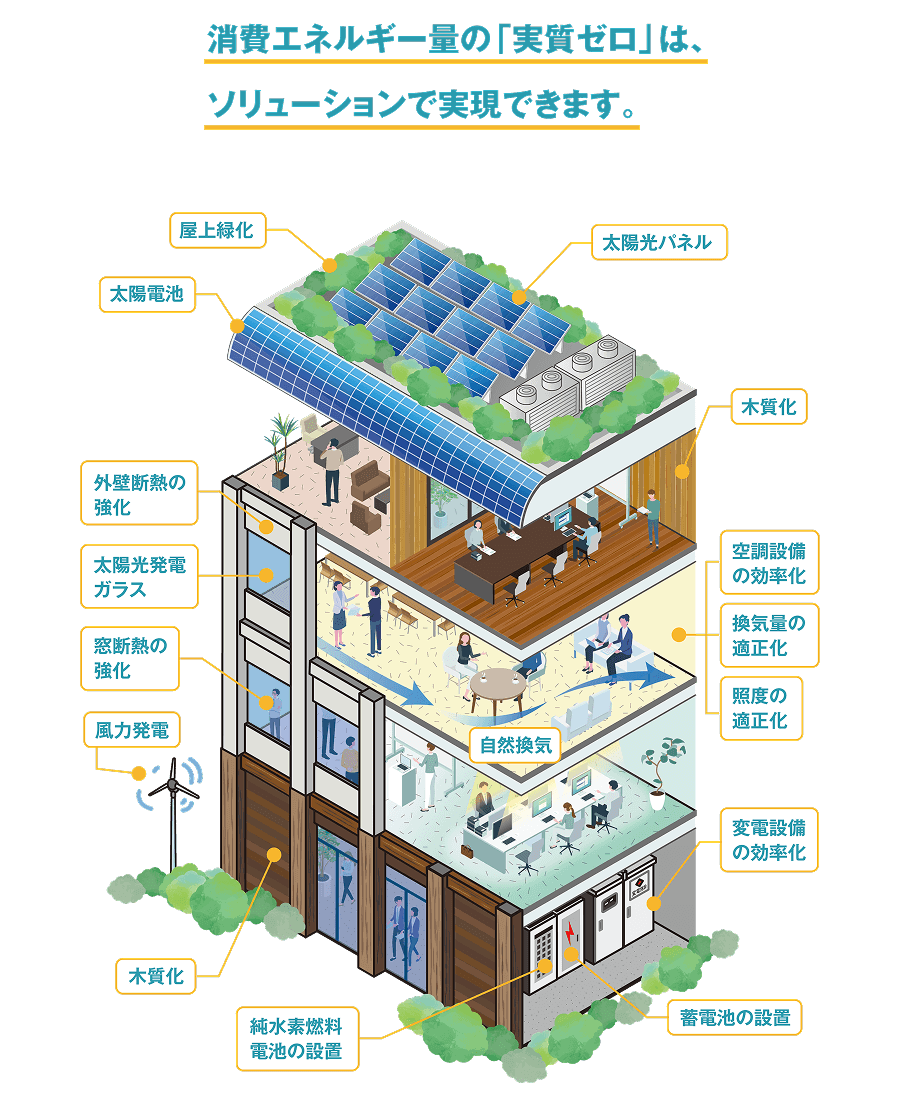

Zero-Energy Building (ZEB) Renovations

Energy-saving features

are now standard in new buildings.

Our challenge is

decarbonizing existing ones.

- Decarbonizing existing buildings all starts with determining whether a building has the potential to become a ZEB.

-

As demand grows to reduce energy consumption during building operation, it has become standard practice to design new buildings with energy-saving specifications.

But can existing buildings be brought up to the same level of performance? The answer isn’t always yes. Buildings that lack the right “potential” may require massive renovation costs without yielding sufficient benefits.

That’s why we first focused on developing a tool to assess that potential. We believe that “visualizing” the possibilities will help many buildings be reborn with advanced energy-saving performance.

Energy consumption inside buildings

is often less visible than we think—

making it “visible”

is the first step toward decarbonization.

Strong support for visualization and planning

Supporting investment effect analysis

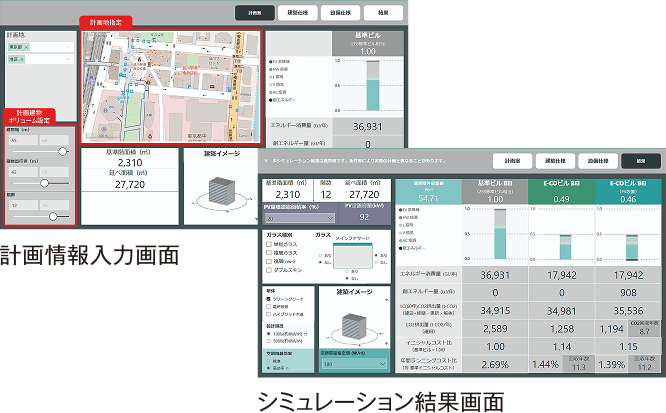

Carbon Designer E-CO BUILDER

Obayashi Corporation has integrated and advanced its CO2 emissions forecasting system, “Carbon Designer,” and its building energy-saving design tool, the “ZEB Ready Simple Evaluation System.” This enables instant comparison and verification of CO2 reduction effects and cost fluctuations during the early stages of building planning.

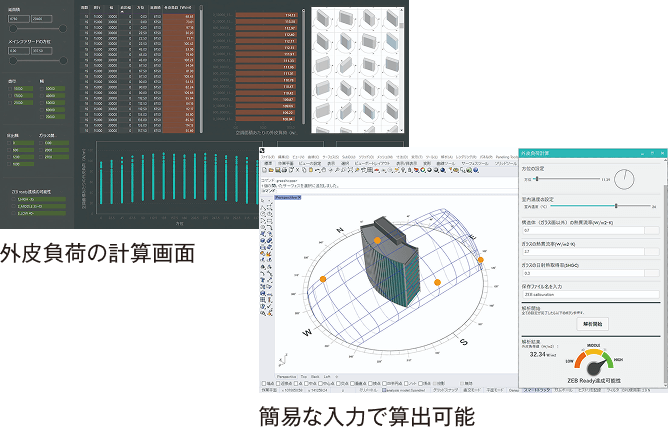

Quick and accurate evaluation through simple calculations

ZEB Ready Simple Evaluation System

By using a simplified 3D model to calculate building envelope loads, this tool enables evaluation of the feasibility of achieving ZEB Ready at the early design stage—before equipment specifications are determined. Even architectural designers without specialized knowledge can verify the effects of building shape, orientation, windows, and eaves within seconds.

“First in Japan” achievements

and expertise—

These are the foundations

on which we are driving forward ZEB construction.

-

-

Obayashi Technical Research Institute Techno-Station

-

Kubota New R&D Hub

©Shinwa

-

Kyowa Kirin Ube Mirai Project

©Masaya Yoshimura

-

Mitsui Fudosan Logistics Park Zama

©Kai Kanno / Nacasa & Partners Inc.

-

-

-

GLION ARENA KOBE

-

Yamaha Headquarters Building No. 22

-

Daido Life Hiroshima Building

©YOSHIHIRO ASADA/ViBRAphoto

-

Yokohama Symphostage

©SS

-

Smart Building Spaces

Our solutions to actualize ever-evolving smart buildings: reducing environmental impact while achieving economic efficiency.

- Visualize Built Environmental Performance to Increase the Value of Your Buildings.

-

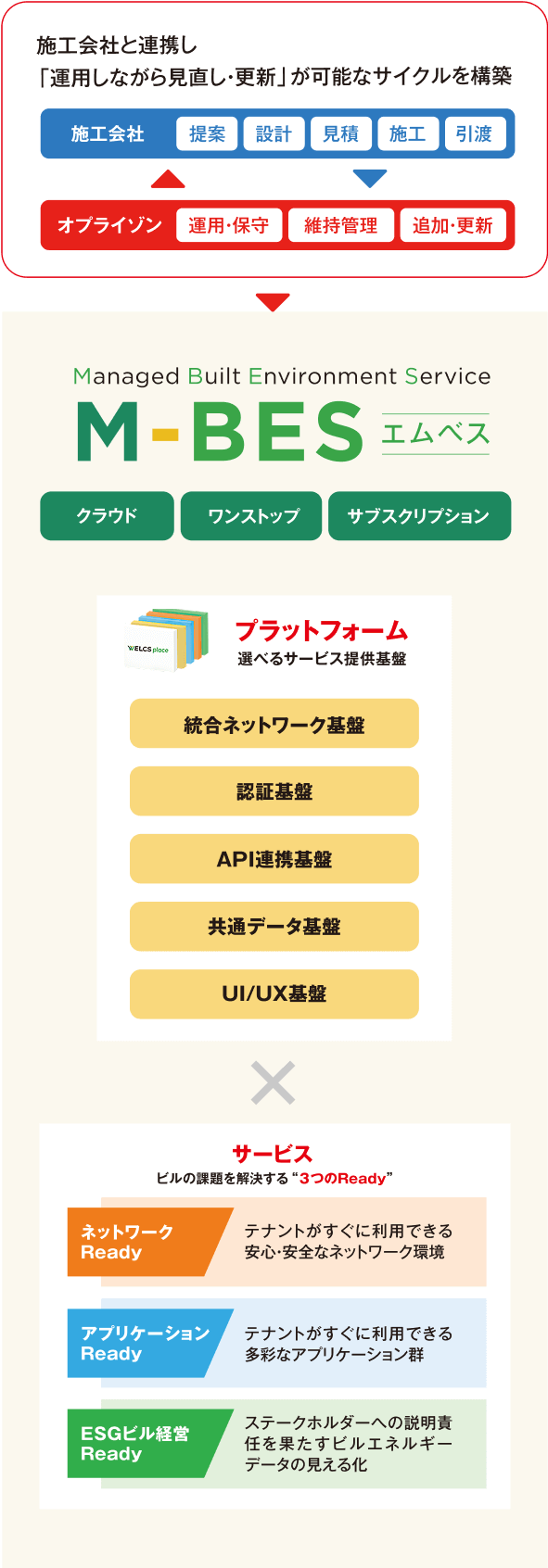

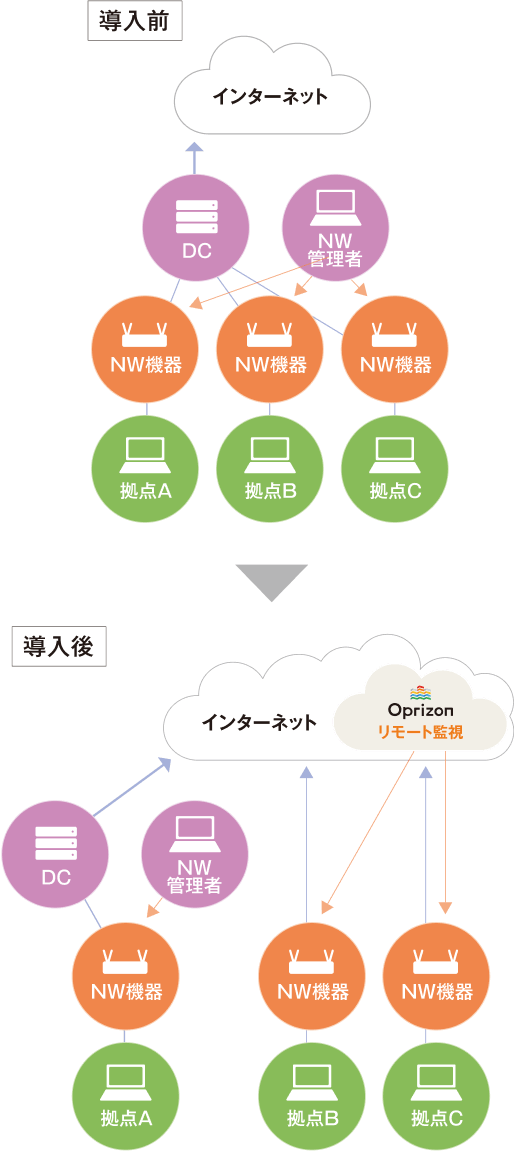

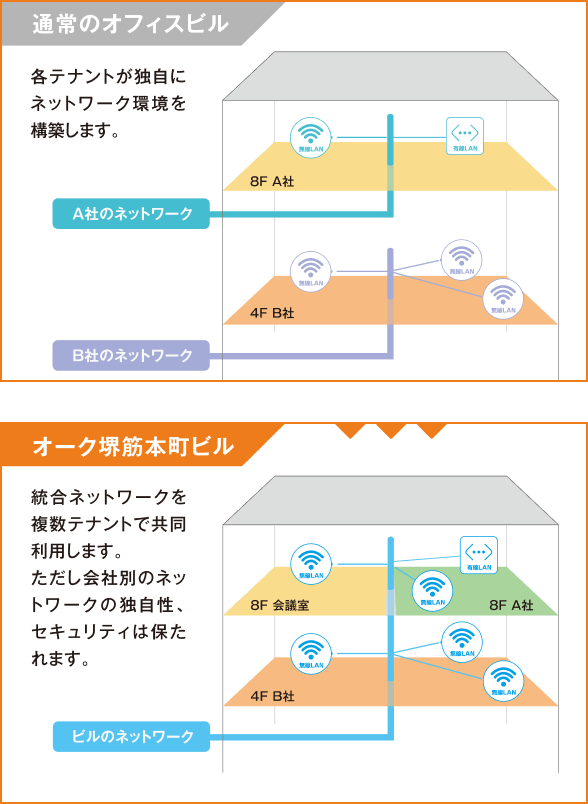

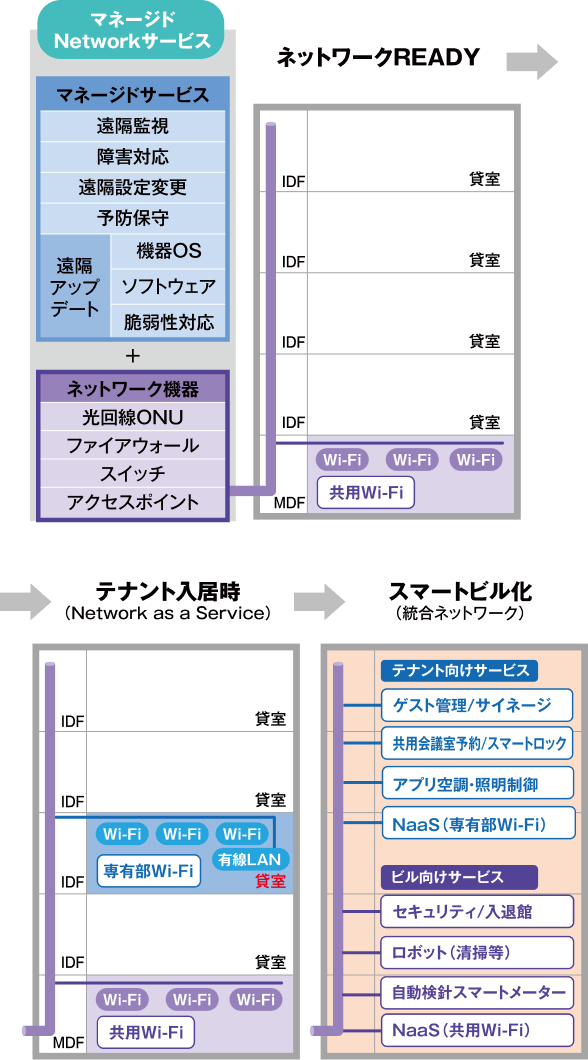

Even if you want to further improve a building’s operational efficiency, the common practice of tenants introducing their own networks and applications often stands as an obstacle. We believe a scalable, unified network plays a crucial role to visualize built environmental data, keeping the building updated with the latest technologies over time. As such we have launched a One-Stop service that covers what you need—from network construction to environmental data monitoring, analysis, and certification acquisition. You might say this is an innovation that enhances the value of buildings while achieving energy savings.

We provide valuable experiences by offering a smooth connection between humans and devices in our Built Environment.

Maintain Constantly Evolving Smart Buildings

Smart Building Services

Obayashi Corporation and Hitachi Solutions jointly established the smart building service provider, Oprizon. Combining their expertise and know-how in building implementation and IT services, Oprizon offers services that keep smart buildings continually updated over years.

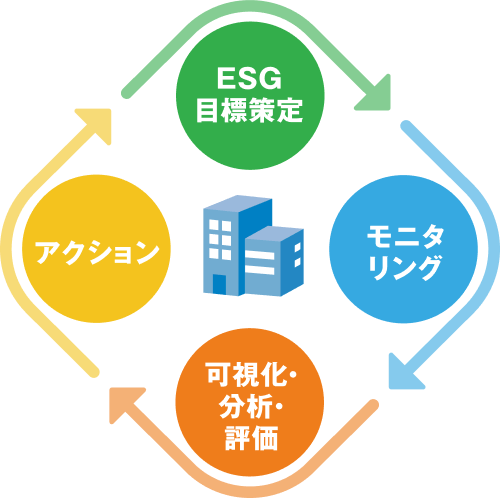

Implement the ESG Building Management Cycle

Managed ESG Service

The service puts into practice the ESG building management cycles: ESG goals setting; Data monitoring; Visualization/Analysis/Evaluation; Action, enhancing building value for all stakeholders by means of energy savings, building certifications and such.

Oprizon's managed services are brought in the next generation of smart buildings.

Introducing NaaS into a Large-Scale Office Environment

Hitachi Solutions Tower

Work out the smooth deployment by a seamless transition from legacy IT systems to modernized NaaS, replacing the existing network ensuring zero downtime for the workforce.

Multiple Services Introduced into a 40-Year-Old Building

Oak Sakaisuji-Hommachi Building

Deploy unified network with safe and secure office network environment for immediate use. It also introduces a meeting reservation system along with smart locks as well as an air quality control system with AI sensing.

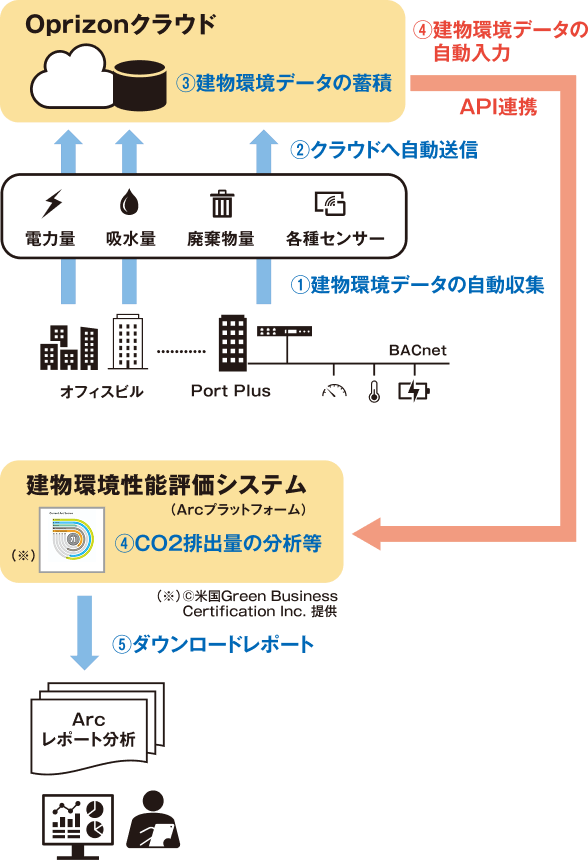

Visualizing Building Environmental Data with "Oprizon Open BMS"

Port Plus Obayashi Yokohama Training Center

By linking with the performance assessment tool "Arc" via API, the system automatically extracts building data and generates CO2 emissions analysis reports. This functionality has been actualized in the building for the first time in Japan.

Deploy Unified Network to meet needs of future expansion

Yokohama Symphostage

Introduced Managed Network Service (NaaS) as a building IT backbone (unified network), which can be used for tenants as well as for building services.

©SS

©SS

SOCIAL PROBLEM Renovation

- We renovate infrastructure in ways that are environmentally friendly—both during construction and over the long term.

-

Renovation work involves many people, machines, and vehicle movement at the site, all of which result in CO2 emissions. However, by extending the lifespan of structures through renovation, we can reduce total CO2 emissions over the long run—making it a vital effort.

At the same time, roadwork often causes traffic congestion, which leads to fuel consumption and CO2 emissions from idling and detours—emissions not directly caused by the renovation work itself.

We face these challenges head-on.

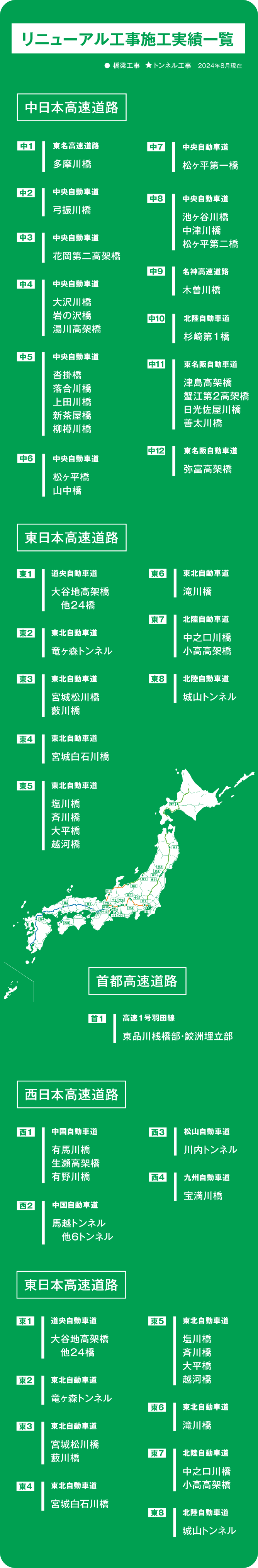

Infrastructure Renewal

Avoiding traffic congestion—

that is also an important environmental consideration

in road maintenance.

- By bringing together “non-stop” technologies, we have realized renovation works that also contribute to decarbonization.

-

What contributes to the decarbonization in highway renewal projects? One approach is to shorten construction time and reduce CO2 emissions during the work itself. However, in road construction, there’s another major challenge: traffic congestion, which can actually increase CO2 emissions. That’s where we focused our attention.

We developed a range of technologies to reduce traffic congestion, integrated them, and applied them to highway renewal projects. Today, we continue working on roadworks across Japan without ever bringing traffic to a halt.

Keeping both traffic

and construction flowing smoothly—

That’s the kind of highway renewal

we’re carrying out across Japan.

Obayashi's Technologies for Alleviating Traffic Congestion During Renewal Work

-

DAYFREE

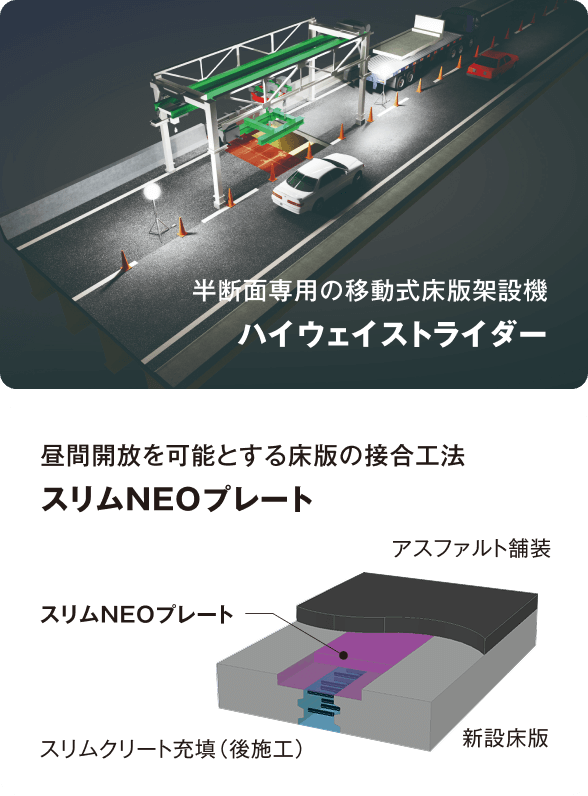

See MoreA new construction method that replaces deck slabs by closing only a single lane during low-traffic nighttime hours. By combining specialized equipment, a proprietary slab-jointing method, and a temporary deck system, it enables work within limited time and space—allowing full traffic flow during the day.

Technologies that make DAYFREE possible

-

HOLLOWAL

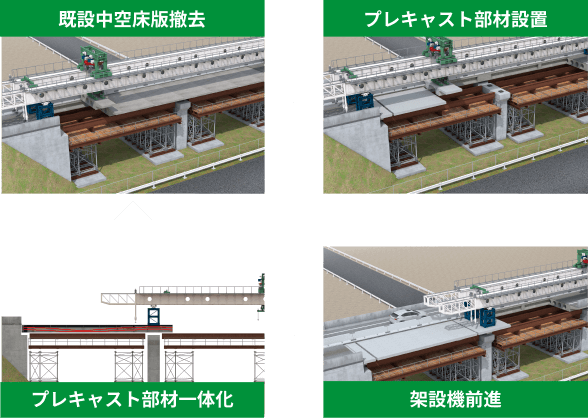

See MoreA new replacement method using precast segments designed for widthwise (transverse) split construction. Since the components are factory-made in advance and simply assembled on-site, the method allows rapid construction without weather-related delays, cutting the lane closure period to half that of conventional methods.

-

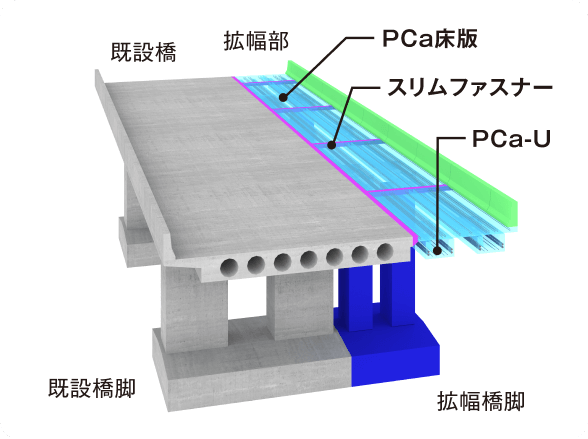

PC Wider

See MoreBy using precast (PCa) components and optimizing the arrangement of prestressing steel, this method enables widening of bridges with low girder heights while maintaining the same girder height as the existing structure. It reduces the amount of concrete and prestressing steel required for the superstructure extension and can shorten the traffic restriction period to one-third of that required by conventional methods.

-

Compact-Invert

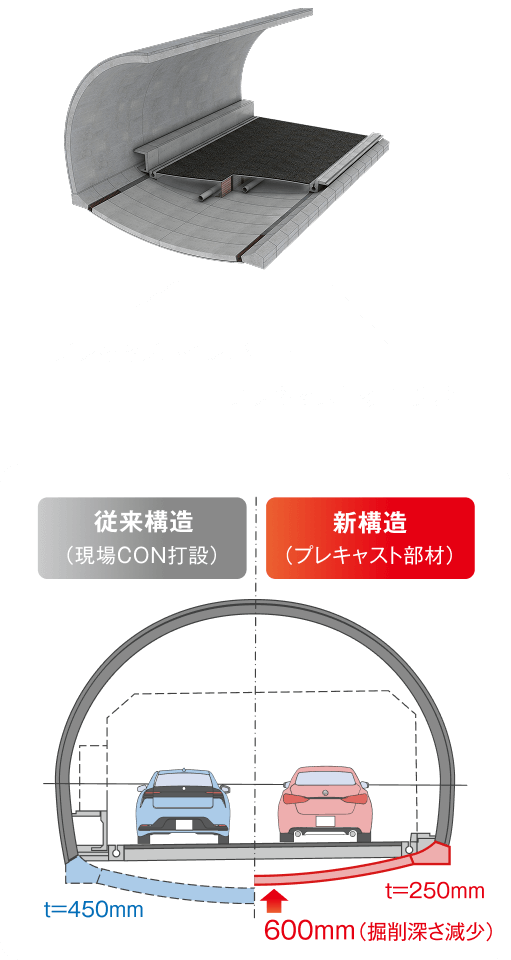

See MoreThis new invert structure maintains the original curvature while reducing thickness by using high-strength reinforced concrete, allowing installation in locations that avoid interfering with utilities. Both the invert and the lining support sections are precast units, which reduces the labor required for the connection between the invert and the lining.

-

One-Bind Cross

See MoreSince reinforcement can be completed with a single layer of sheet, the construction process is shortened. The use of wide-format sheets (1 meter wide) also improves installation efficiency. The specially manufactured carbon fiber sheets also provide the same strength with one layer as in the conventional two layer method, preventing delamination between layers

-

Stiff-Crete

See MoreAchieves the required strength within 3 hours after placement, enabling early reopening to traffic. Its ultra-high strength and durability extend the service life of deteriorated concrete deck slabs. With a dedicated truck-mounted plant, it can also be used for construction within a single-lane closure.

-

Chapter 02 VISION

Obayashi’s Vision for a Decarbonized Society

See MoreExplore the Obayashi Group’s wide-ranging visions and technologies aimed at achieving a decarbonized society—extending beyond the boundaries of the construction industry. Themes include resource circulation, biodiversity, energy, and transportation infrastructure.

-

Chapter 03 CREATION

Realizing a Decarbonized Society and Creating New Social Value

See MoreExplore the many new value creation initiatives the Obayashi Group is making toward realizing a decarbonized society—starting with its efforts at Expo 2025 Osaka, Kansai, Japan.